Support any customized shapes, sizes, dimensional accuracy and surface treatments in diversity of advanced ceramic materials.

Not only own various forming, sintering and post-processing equipment, but also mold design and assembly capabilities.

Scientific quality-control personnel structure, well-trained operators and stringent quality-control flow charts from incoming materials to shipping.

Jinghui - A Reliable Advanced Ceramics Factory in China

Jinghui has specialized in R&D and advanced ceramics manufacturing since 2008. We offer a wide variety of customized ceramic parts, tailored to different materials, shapes, sizes, surface treatments, and levels of dimensional accuracy.

We implement quality control as the first red line of the enterprise, adhere to the principle of customer commitment first, and provide 24-hour service by dedicated personnel. We have gained the trust and in-depth cooperation of 1,000+ customers from all over the world. Based on our advanced and complete production facilities and innovative and experienced R&D, engineering, and production teams, you will get the most outstanding support from your prototype design to the final product quality assurance.

We embrace the motto “Happy Clients, Happy Teams” so that every client and employee can feel at home and gain a sense of achievement. At the same time, we focus on the future, and a sustainable development strategy is the top priority of business operations.

If you are looking for a better ceramic solution, please contact us today. You will get five-star plus service and satisfactory products from here.

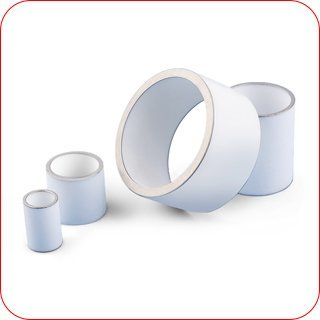

Custom Advanced Ceramic Parts Tailored to Your Needs

After fully understanding your needs, we will carefully customize the production process to ensure that your requirements can be realized. Our engineers provide tailored solutions through the following services:

- We fully consider the characteristics of advanced ceramic materials to ensure the feasibility of the design.

- Our professional technical team tailors production and processing solutions.

- We use ceramic forming technology to form ceramic compounds into desired shapes.

- We trim the green ceramic body to make it reach the required size and then sinter it.

Additionally, we can carry out ceramic machining, surface treatment, etc., according to the design requirements.

Main Products

Metallized ceramics are functional components, which can realize ceramic-to-metal bonding directly with ideal connection strength and vacuum tightness.

Grinding burrs are vital parts like the soul in seasoning and coffee mills. The quality of the grinding burr will affect the particle size of the ground powder, and thus affect the taste.

Jinghui produces a variety of ceramic substrates, providing material selection and customized size, pattern and surface treatment.

We can produce a wide range of precision ceramics in different materials, sizes, machining accuracy, etc. to meet your bespoke needs.

Your tailored ceramic to metal brazing supplier in China, empower your components with ultra-high vacuum requirements and reliable connections.

Jinghui supplies many standard pepper mill grinder mechanisms for your seasoning grinders, and can customize them to your specifications.

Typical Applications of Advanced Ceramics

Jinghui can manufacture any ceramic parts for your application. Just send us your drawings to get our best quote.

We produce metallized ceramic tubes and isolators for the electronics and power industries.

Jinghui can produce household parts such as ceramic burrs and pepper mill grinder mechanisms, which are key components of pepper grinders and salt grinders.

We can provide ceramic PCBs such as blank ceramic substrates, metalized ceramic substrates and more.

Why Jinghui is Trusted by 1000+ Customers

Our custom advanced ceramic products benefit your business or project. Here are the advantages of our services.

Exquisite craftsmanship and professional manufacturing technology make our advanced ceramic products stand out from similar products. They become representatives of high quality and reflect our pursuit of excellence.

We reduce production costs through refined management and pass the profits on to you. We provide you with cost-effective solutions that deliver higher quality and better performance at the same price.

Our 24-hour online service ensures that you can contact our expert team for support at any time.

-

Ceramic Parts Fabrication Equipment

Jinghui has comprehensive manufacturing equipment for ceramic parts such as:

- Ball Milling & Mixing Machine

- Spray Granulation Machine

- Dry Pressing Machine

- Hot Pressing Machine

- Isostatic Pressing Machine

- Extrusion Shaping Machine

- Ceramic Injection Molding Machine

- High-temp Sintering Furnace

-

Available Secondary Processing

Our facility offer a wide range of secondary processing to enhance the performance of ceramic parts and deepen their uses.

- Grinding

- CNC Machining

- Lapping

- Polishing

- Glazing

- Laser Cutting and Scribing

- Metallizing

- Ceramic-to-Metal Brazing

Materials You Can Choose for Advanced Ceramics

Jinghui utilizes a diverse range of advanced ceramic materials for your ceramic parts. Our selection includes alumina, zirconia, silicon nitride, aluminum nitride, boron nitride, and more. Each material comes in different grades and varieties with designated additives. These materials possess distinct mechanical, thermal, electrical, and chemical properties. If you are looking for a specific material for your ceramic components, please don’t hesitate to consult with our technical ceramic experts.

Featured Ceramic Parts

Jinghui provides more customized featured products, such as:

What Our Customer Say

-

We accept you and your company as our long term partner. We have to support each other to make more valuable business in the future.

Canerfrom Turkey

Canerfrom Turkey -

Thank you for your design proposal, we will send the new 3D data to our R&D colleagues for further evaluation and confirmation.

Easonfrom Russia

Easonfrom Russia -

Thank you for the detailed explanation on the design. Please see attached comments from our team on your proposed design.

Madhufrom USA

Madhufrom USA -

Please find our internal report from the sample you sent. In general samples look good, thanks!

Abraham Khofrom Indonesia

Abraham Khofrom Indonesia -

This batch of metallized ceramic parts was delivered on time and the quality is very good. Well done!

Ginafrom Slovenia

Ginafrom Slovenia