Cordierite Material Overview

Cordierite ceramic is a magnesium aluminum silicate advanced ceramic material, chemically expressed as 2MgO·2Al₂O₃·5SiO₂. It is best known for its ultra-low thermal expansion coefficient, outstanding thermal shock resistance, and excellent dimensional stability under rapid temperature changes.

Unlike high-strength structural ceramics such as alumina or zirconia, cordierite ceramics are specifically engineered for applications where thermal cycling resistance, lightweight design, and cost efficiency are more critical than mechanical strength. As a result, cordierite ceramics are widely used in catalytic converter substrates, ceramic burner plates, kiln furniture, and thermal insulation components.

Because of its stable crystal structure and low internal thermal stress, cordierite ceramic maintains integrity under repeated heating and cooling cycles, making it one of the most reliable materials for high-temperature thermal management systems.

Typical Properties of Cordierite Ceramic

| Property | Cordierite Ceramic |

|---|---|

| Density (g/cm³) | 2.1 – 2.5 (bulk); 1.9 – 2.3 (honeycomb) |

| Flexural Strength (MPa) | ~55 |

| Modulus of Elasticity (GPa) | ~140 |

| Thermal Conductivity (W/m·K) | ~1.6 |

| Thermal Expansion Coefficient (×10⁻⁶/°C) | 1 – 3 |

| Maximum Service Temperature (°C) | ~1300 |

| Dielectric Strength (kV/mm) | ~19 |

Engineering note: Cordierite’s strength is lower than alumina ceramics, but its thermal shock resistance is significantly superior, making it ideal for thermally demanding but mechanically moderate environments.

Cordierite Ceramic Products & Forms

Cordierite ceramics can be manufactured into a variety of shapes depending on application requirements. Jinghui mainly supplies cordierite ceramics optimized for thermal shock resistance and high-temperature stability.

Common cordierite ceramic product forms include:

-

Cordierite honeycomb ceramic substrates

-

Cordierite kiln shelves and refractory supports

-

Cordierite thermocouple protection tubes

-

Custom-shaped cordierite ceramic components

These products are widely used in automotive exhaust systems, industrial furnaces, combustion equipment, and thermal insulation assemblies.

-

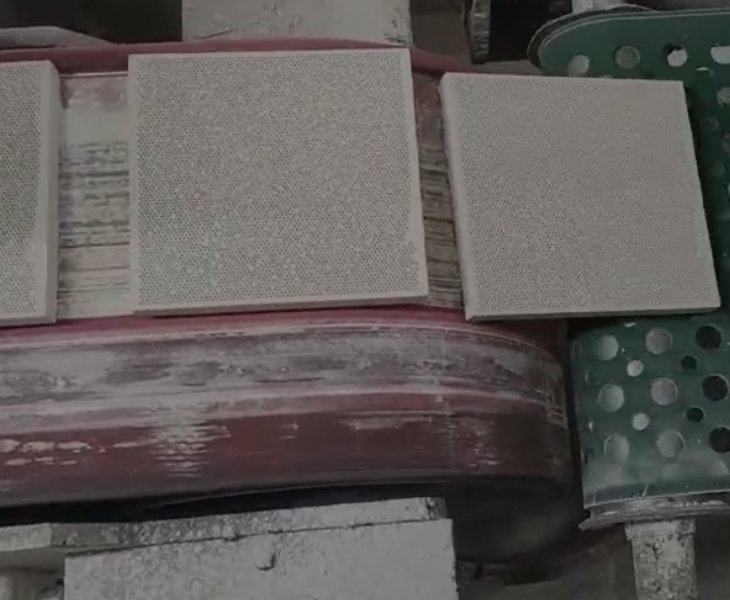

Honeycomb Ceramic Plate

Honeycomb Ceramic Plate -

Cordierite Ceramic Tube

Cordierite Ceramic Tube -

Ceramic Heating Elements

Ceramic Heating Elements

Key Advantages of Cordierite Ceramics

With a thermal expansion coefficient as low as 1–3 × 10⁻⁶/°C, cordierite ceramics experience minimal dimensional change during rapid heating and cooling.

Cordierite components can withstand sudden temperature changes of 300–350°C without cracking, making them ideal for exhaust systems and combustion environments.

Cordierite ceramics are approximately 30–40% lighter than alumina ceramics, reducing thermal mass and improving energy efficiency in high-temperature systems.

Cordierite exhibits strong resistance to acids, alkalis, and combustion exhaust gases, ensuring long service life in chemically aggressive conditions.

Low dielectric loss and high electrical resistivity make cordierite suitable for insulation and electronic support applications.

Cordierite Ceramics Engineering Considerations

To ensure correct material selection, it is important to understand the limitations of cordierite ceramics:

-

Lower mechanical strength compared to alumina and zirconia

-

Not suitable for heavy structural load-bearing applications

-

Limited resistance to prolonged contact with molten metals

Cordierite ceramics perform best in applications dominated by thermal stress rather than mechanical stress.

Typical Applications of Cordierite Ceramic Materials

Automotive & Emission Control

Cordierite honeycomb ceramics are the industry-standard substrate material for catalytic converters, accounting for over 85% of ceramic catalyst carriers due to their low thermal expansion and high thermal shock resistance.

Combustion & Heating Systems

Cordierite ceramic burner plates promote uniform combustion, reduce carbon monoxide emissions, and maintain structural stability under repeated ignition cycles.

Industrial Furnace & Kiln Equipment

Cordierite kiln furniture, shelves, and supports maintain flatness and integrity under repeated thermal cycling, improving furnace efficiency and service life.

Electronics & Thermal Insulation

Cordierite ceramics are used as insulating components and structural supports in high-temperature electronic and thermal management systems.

Related Materials

-

ZTA ceramics combine the hardness of alumina with the toughness of zirconia, making them suitable for cutting tools and wear-resistant components.

-

Mullite ceramics are resistant to high temperatures and have low thermal expansion, making them suitable for use in kiln furniture and refractory materials.

-

The machinable ceramics have excellent machinability and can be machined using traditional metalworking tools.

-

Steatite ceramics are low-cost, high-frequency insulators, and have low mechanical strength, making them suitable for use in general equipment parts.

-

Silicon carbide ceramics are advanced ceramics with semiconductor properties and resistance to high-temperature corrosion, making them suitable for power devices and high-temperature structural components.

Cordierite Ceramic Manufacturing & Customization

Sintering & Material Control

Cordierite ceramics are typically sintered at approximately 1350°C, achieving high phase purity and optimized thermal properties. Raw material selection and firing profiles are carefully controlled to ensure consistent thermal shock resistance.

Additive & Formulation Optimization

Selected dopants may be introduced to improve microstructural stability or fracture resistance under specific application conditions.

Custom Shapes & Machining

Custom cordierite ceramic components can be supplied with dimensional tolerances of ±0.02 mm, depending on geometry and structure.

Cordierite ceramic is the preferred substrate material for catalytic converters because its ultra-low thermal expansion prevents cracking during rapid exhaust temperature fluctuations, which can exceed 1000°C within seconds.

Its honeycomb structure provides:

-

High surface area for catalytic reactions

-

Low exhaust backpressure

-

Excellent resistance to thermal fatigue

Compared with metallic substrates, cordierite honeycomb ceramics reduce backpressure by approximately 15–20%, contributing to improved fuel efficiency and long-term emission control stability.

No. Cordierite ceramics are composed of stable inorganic minerals and do not release harmful substances at operating temperatures below 1300°C. They are non-toxic, odorless, and environmentally friendly.

Raw materials such as talc, kaolin, and alumina directly affect phase purity, porosity, and thermal properties. Proper pre-calcination and formulation control are critical for achieving high thermal shock resistance.

Yes. Cordierite ceramics show excellent resistance to acids, alkalis, and combustion gases. In industrial applications, cordierite components demonstrate minimal degradation even after years of exposure.