Mullite Ceramic Material Overview

Mullite ceramic is an aluminosilicate advanced ceramic material with the chemical composition 3Al₂O₃·2SiO₂. It is one of the most stable ceramic phases at elevated temperatures and is widely recognized for its excellent thermal stability, low thermal expansion, strong thermal shock resistance, and chemical inertness.

Unlike alumina ceramics, which prioritize mechanical strength, mullite ceramics are specifically suited for applications requiring long-term exposure to high temperatures combined with repeated thermal cycling. Its unique needle-like crystal structure effectively inhibits crack propagation, allowing mullite components to maintain structural integrity in harsh thermal environments.

As a result, mullite ceramics are extensively used in kiln furniture, refractory linings, furnace components, and high-temperature insulation systems across industrial, energy, and materials processing sectors.

Typical Properties of Mullite Ceramic

| Property | Mullite Ceramic |

|---|---|

| Density (g/cm³) | 2.8 – 3.1 |

| Flexural Strength (MPa) | 100 – 150 |

| Modulus of Elasticity (GPa) | 150 – 170 |

| Thermal Conductivity (W/m·K) | ~5 |

| Thermal Expansion Coefficient (×10⁻⁶/°C) | 4.5 – 6.0 (RT–1000°C) |

| Maximum Service Temperature (°C) | ~1600 |

| Dielectric Strength (kV/mm) | >20 |

Engineering insight: Mullite ceramics offer a balanced combination of thermal stability and mechanical reliability, positioning them between alumina and cordierite in high-temperature applications.

Mullite Ceramic Products & Forms

Jinghui supplies mullite ceramics primarily for refractory and high-temperature structural applications, where dimensional stability and thermal shock resistance are critical.

Common mullite ceramic product forms include:

-

Mullite ceramic crucibles

-

Mullite ceramic plates and slabs

-

Mullite ceramic rods and tubes

-

Mullite kiln furniture components

-

Custom-shaped mullite refractory parts

These products are widely used in industrial furnaces, heat treatment equipment, and materials processing systems operating under continuous high-temperature conditions.

-

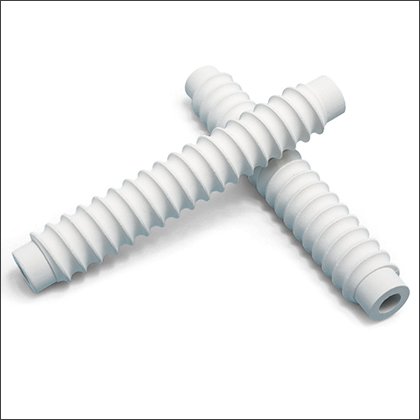

Mullite Ceramic Tubes

Mullite Ceramic Tubes -

Ceramic Electrical Insulator

Ceramic Electrical Insulator -

Kiln furniture

Kiln furniture

Key Advantages of Mullite Ceramics

Mullite maintains structural integrity and phase stability at temperatures up to 1600°C, making it suitable for continuous high-temperature service.

Its needle-like microstructure deflects cracks and reduces thermal stress accumulation, enabling reliable performance during repeated heating and cooling cycles.

Mullite resists most acids (except HF), alkalis, and molten slags, ensuring long service life in chemically aggressive furnace and kiln environments.

Lower thermal conductivity than alumina helps improve energy efficiency and temperature uniformity in high-temperature systems.

Limitations of Mullite Ceramics

To ensure proper material selection, the following limitations should be considered:

-

Lower mechanical strength compared with alumina ceramics

-

Higher thermal conductivity than cordierite ceramics

-

Not suitable for precision load-bearing or impact-resistant applications

-

Limited resistance to prolonged contact with molten metals

Mullite ceramics perform best in environments dominated by thermal stress rather than mechanical stress.

Typical Applications of Mullite Ceramic Materials

Refractory & Kiln Furniture Applications

Mullite ceramics are extensively used for:

-

Kiln shelves and setters

-

Furnace linings and structural supports

-

Heat treatment fixtures

Their resistance to thermal deformation and thermal shock significantly extends service life compared with conventional refractory materials.

High-Temperature Industrial Equipment

Mullite components are used in:

-

Furnace insulation structures

-

Thermocouple protection tubes

-

High-temperature processing equipment

Electronics & Insulation Applications

Due to low dielectric loss and thermal expansion compatibility with silicon, mullite ceramics are used in selected electronic substrates and insulating components operating at elevated temperatures.

Related Materials

-

ZTA ceramics combine the hardness of alumina with the toughness of zirconia, making them suitable for cutting tools and wear-resistant components.

-

Cordierite ceramics have ultra-low thermal expansion and are resistant to thermal shock, making them suitable for use as catalyst carriers and thermal insulation materials.

-

The machinable ceramics have excellent machinability and can be machined using traditional metalworking tools.

-

Steatite ceramics are low-cost, high-frequency insulators, and have low mechanical strength, making them suitable for use in general equipment parts.

-

Silicon nitride ceramics are high-strength, lightweight, and thermally shock resistant advanced ceramics commonly used in bearings and turbine components.

Mullite Ceramic Manufacturing & Processing

Solid-State Synthesis

Mullite ceramics are produced by solid-state reaction of alumina and silica-based raw materials (such as kaolin), sintered at temperatures between 1500–1750°C to achieve high phase purity.

Forming & Machining

Depending on geometry, mullite components can be manufactured via pressing, extrusion, or casting. Limited post-sintering machining is available for precision features.

Mullite vs Alumina vs Cordierite (Material Selection Guide)

| Property | Mullite | Alumina | Cordierite |

|---|---|---|---|

| Max. Service Temperature (°C) | ~1600 | ~1700 | ~1300 |

| Thermal Expansion (×10⁻⁶/°C) | 4.5–6.0 | 7–8 | 1–3 |

| Thermal Shock Resistance | High | Moderate | Excellent |

| Mechanical Strength | Medium | High | Low |

| Typical Applications | Kiln furniture, refractories | Structural parts | Catalyst substrates |

Material selection tip: Mullite is ideal when high temperature and thermal cycling resistance are more critical than maximum mechanical strength.

Mullite ceramic is preferred for kiln furniture because it offers an optimal balance between thermal shock resistance, high-temperature stability, and cost efficiency.

Compared with alumina ceramics, mullite exhibits:

-

Lower thermal expansion

-

Reduced risk of cracking during thermal cycling

-

Better resistance to long-term furnace operation

These advantages allow kiln furniture made from mullite to withstand repeated heating cycles from room temperature to over 1200°C with minimal deformation or failure.

Yes. Mullite ceramics are specifically designed for long-term exposure to temperatures up to 1600°C, with excellent resistance to thermal deformation and phase instability.

In many cases, yes. Mullite is preferred when thermal shock resistance and dimensional stability are more important than maximum strength.

Yes. Mullite ceramics can be supplied in custom shapes and sizes for refractory and industrial applications, depending on design and service conditions.