Silicon Nitride Ceramic Overview

Silicon nitride ceramic (Si₃N₄) is a high-performance structural ceramic known for its exceptional mechanical strength, low density, and outstanding thermal shock resistance. Due to its covalently bonded silicon–nitrogen structure and elongated β-phase grain microstructure, silicon nitride exhibits high fracture toughness, excellent wear resistance, and dimensional stability under rapid temperature changes.

Compared with conventional ceramics and metals, silicon nitride maintains reliable performance at temperatures up to 1,400 °C, making it an ideal material for demanding applications in aerospace, automotive, industrial bearings, and precision mechanical systems where strength-to-weight ratio and thermal reliability are critical.

Silicon Nitride Vs Aluminum Nitride – Material Comparison

| Property | Aluminum Nitride (AlN) | Silicon Nitride (Si₃N₄) |

| Density (g/cm³) | ~3.3 | 3.2–3.25 |

| Flexural Strength (MPa) | >310 | >700 |

| Modulus of Elasticity (GPa) | ~310 | 290-310 |

| Thermal Conductivity (W/m·K) | 170–230 | 20-30 |

| Max. service temperature (℃) | ~1200 | ~1400 |

| Dielectric Strength (kV/mm) | >17 | ~13 |

Summary:

Aluminum nitride excels in thermal conductivity for electronic substrates, while silicon nitride is preferred for high-load, high-speed, and high-temperature structural applications, especially bearings and rotating parts.

Silicon Nitride Ceramic Products & Forms

We supply silicon nitride ceramic components in various standard and custom forms, including:

-

Precision silicon nitride structural parts

-

Custom-machined components for bearings and mechanical assemblies

All products can be manufactured according to customer drawings and performance requirements.

-

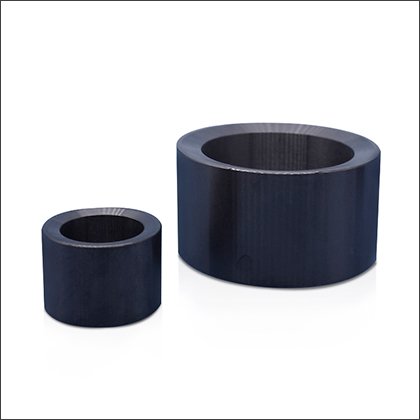

Silicon Nitride Bearings

Silicon Nitride Bearings -

Silicon Nitride Wafer

Silicon Nitride Wafer -

Silicon Nitride Tube

Silicon Nitride Tube -

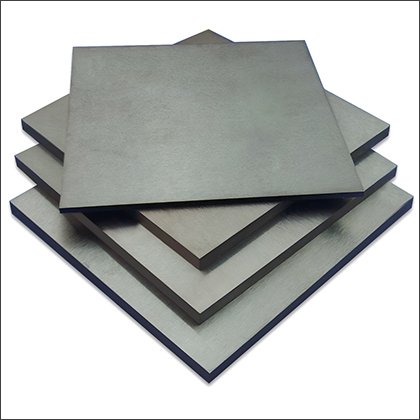

Silicon Nitride Sheet

Silicon Nitride Sheet -

Silicon Nitride Crucible

Silicon Nitride Crucible -

Ceramic Dowel Pins

Ceramic Dowel Pins

Key Properties of Silicon Nitride Ceramic

Operates continuously at temperatures up to 1,400 °C with excellent resistance to thermal shock.

Flexural strength exceeding 700 MPa and compressive strength over 2,500 MPa, outperforming most structural ceramics.

ypical density of 3.2–3.25 g/cm³, reducing centrifugal forces in high-speed rotating components.

High hardness (~1,420 HV) and superior rolling contact fatigue performance.

Excellent resistance to acids, alkalis, oxidation, and molten metals.

Non-conductive behavior prevents electrical arcing in hybrid and electric systems.

Widely used in medical and dental components due to proven biological safety and mechanical reliability.

Applications of Silicon Nitride Ceramics

Industrial and Bearing Applications

-

Hybrid ceramic bearings

-

High-speed spindle bearings

-

Rolling elements and bearing balls

-

Industrial pumps and valves

Silicon nitride bearings enable 30–50% higher rotational speeds than steel bearings while significantly reducing wear and maintenance.

Automotive and Turbocharger Components

-

Turbocharger rotors

-

Diesel engine glow plugs

-

Valve components and wear parts

Silicon nitride turbocharger rotors operate reliably at 1,400 °C, reducing turbo lag and improving engine efficiency under rapid thermal cycling.

Medical and Precision Devices

-

Components for medical equipment

-

Dental and orthopedic ceramic parts

-

Precision mechanical components

Its combination of strength, wear resistance, and biocompatibility makes silicon nitride suitable for long-term medical use.

Related Advanced Ceramic Materials

-

Alumina ceramics are advanced ceramics with excellent comprehensive properties, and they were researched early, are the most widely used, and are the most mature.

-

Zirconia ceramics are second only to alumina ceramics in terms of applicability and are very important advanced ceramics for structural applications.

-

Aluminum nitride ceramics are advanced ceramics with high thermal conductivity and insulation, and are often used in electronic packaging substrates and heat dissipation components.

-

Silicon carbide ceramics are advanced ceramics with semiconductor properties and resistance to high-temperature corrosion, making them suitable for power devices and high-temperature structural components.

-

The machinable ceramics have excellent machinability and can be machined using traditional metalworking tools.

Processing Techniques for Silicon Nitride Ceramics

The final performance of silicon nitride components is closely related to the selected forming and machining processes:

-

Dry Pressing

Suitable for high-density components (≥99%) requiring excellent mechanical strength. -

Injection Molding

Ideal for small, complex, and precision parts such as gears and bearing cages. -

Tape Casting

Used for thin plates and ceramic substrates. -

CNC Machining

Achieves tight tolerances up to ±0.01 mm for precision and medical applications.

Silicon nitride bearings outperform steel bearings due to their low density (≈3.2 g/cm³), high hardness, and excellent thermal stability. Reduced centrifugal force enables 30–50% higher speeds, while low friction minimizes heat generation. In high-vibration environments, silicon nitride bearings can achieve up to 10× longer service life, significantly lowering maintenance costs.

Silicon nitride turbocharger rotors maintain dimensional stability at temperatures up to 1,400 °C due to low thermal expansion. This improves transient response and reduces turbo lag by approximately 15% compared with metal alloys. The material’s resistance to thermal shock also extends service life under cyclic heating conditions.

Silicon nitride substrates can replace aluminum-based substrates in high-power or high-temperature electronic modules, such as IGBT systems, where mechanical strength and thermal reliability are critical. However, aluminum or aluminum nitride substrates remain more cost-effective for general heat-dissipation applications. A hybrid material strategy is often used to balance performance and cost.