Material Overview

Aluminum Nitride (AlN) is a cutting-edge ceramic material renowned for its exceptional thermal conductivity (up to 170 W/mK), low thermal expansion coefficient (4~6×10⁻⁶/K), and superior electrical insulation (resistivity >10^13 Ω·cm), so AlN is deal for thermal management and electrical applications. Composed of aluminum and nitrogen, this non-oxide ceramic features a hexagonal wurtzite crystal structure, making it ideal for high-power electronics, aerospace components, and advanced semiconductor packaging.

Technical Data Table

| Property | AlN (99% Purity) | AlN (Enhanced) |

| Density (g/cm³) | 3.3 | 3.32 |

| Flexural Strength (MPa) | >310 | >310 |

| Modulus of Elasticity (GPa) | 310 | 310 |

| Thermal Conductivity (W/m·K) | 170–230 | 230 |

| Max. service temperature (℃) | 1200 | 1200 |

| Dielectric Strength (kV/mm) | >17 | >17 |

Aluminum Nitride Productions

The aluminum nitride power is processed into complex geometric shapes through relevant forming processes. Then it is sintered for densification. The sintering process causes the aluminum nitride parts to shrink by about 20%. After sintering, it must be ground with diamond tools until the desired shape is achieved. In order to fully demonstrate the high thermal conductivity of AlN, the AlN substrate is common product form with a thickness of no more than 1 mm, which is then laser cut into the required specifications. The following displays are common aluminum nitride products of Jinghui Company, which can be processed according to your customized needs.

-

Aluminum Nitride Wafer

Aluminum Nitride Wafer -

Aluminum Nitride Sheet

Aluminum Nitride Sheet -

Aluminum Nitride Heater

Aluminum Nitride Heater -

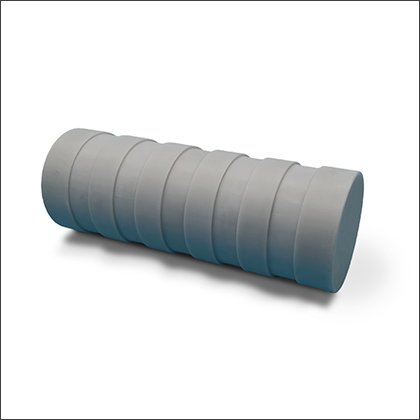

Aluminum Nitride Rod

Aluminum Nitride Rod -

Aluminum Nitride Insert

Aluminum Nitride Insert -

Aluminum Nitride Parts

Aluminum Nitride Parts

Core Properties That Exceed Limits

When your design faces thermal dissipation bottlenecks, high-frequency losses, or challenging environmental conditions, ordinary materials often fall short. Aluminum nitride ceramics, with their unique crystal structure and material science properties, offer a comprehensive solution.

The most striking characteristic of aluminum nitride is its extremely high thermal conductivity. Its theoretical value can reach 320 W/(m·K), and in actual industrial production, you can easily obtain high-conductivity products with values ranging from 170 to 260 W/(m·K). This means that it can quickly dissipate the heat generated by chips, with an efficiency several times higher than traditional alumina substrates. For modern electronic devices that require high power density (such as IGBT modules and high-power LEDs), this characteristic directly relates to the system’s stability and lifespan.

Thermal stress is one of the main causes of packaging failure. The thermal expansion coefficient of aluminum nitride ceramic (approximately 4~6× 10⁻⁶/℃) is very close to that of major semiconductor materials such as silicon (Si) and gallium arsenide (GaAs). This matching ensures that during drastic temperature cycles, significant stress will not be generated between the chip and the substrate due to uneven expansion and contraction, thus greatly improving the reliability and durability of the packaging structure.

In addition to its thermal conductivity, aluminum nitride is also an excellent electrical insulator, possessing high volume resistivity, a low dielectric constant, and low dielectric loss. This makes it perform exceptionally well in high-frequency, high-power radio frequency (RF) and microwave circuits, effectively reducing signal transmission delays and energy losses. It is an ideal substrate material for 5G communication and radar systems.

Aluminum nitride ceramics possess high hardness and good mechanical strength, enabling them to withstand considerable mechanical loads. More importantly, they exhibit excellent chemical stability and high-temperature resistance, remaining stable in air and at high temperatures, and demonstrating excellent corrosion resistance to molten metals (such as aluminum). This makes them suitable not only for electronic packaging but also for the demanding requirements of core components such as electrostatic chucks and heating plates in semiconductor manufacturing equipment.

Other Advanced Ceramic Materials

-

Alumina ceramics are advanced ceramics with excellent comprehensive properties, and they were researched early, are the most widely used, and are the most mature.

-

Zirconia ceramics are second only to alumina ceramics in terms of applicability and are very important advanced ceramics for structural applications.

-

Steatite ceramics are low-cost, high-frequency insulators, and have low mechanical strength, making them suitable for use in general equipment parts.

-

The machinable ceramics have excellent machinability and can be machined using traditional metalworking tools.

-

Silicon carbide ceramics are advanced ceramics with semiconductor properties and resistance to high-temperature corrosion, making them suitable for power devices and high-temperature structural components.

Having superior materials is only the first step; processing them into precision components that meet stringent requirements is the key to realizing their value. Jinghui Ceramic possesses extensive technical expertise and full-process control capabilities in this field..

Applications

- Electronics: Substrates for high-frequency circuits, LED packaging, and power modules.

- Aerospace: Radomes, thermal management systems, and engine sensors.

- Semiconductors: Dielectric isolation layers and heat sinks for ICs.

- Industrial: Crucibles for molten metal handling and high-temperature furnace components.

Manufacturing & Customization

- Forming Method: Dry pressing is suitable for simple shapes and has high efficiency; tape casting can prepare ultra-thin substrates..

- Advanced Machining: Laser cutting, grinding and cutting.

- Composite Enhancements: Adding SiC or Y₂O₃ improves fracture toughness (up to 4.5 MPa√m) for demanding applications.

Aluminum nitride outperforms alumina due to its 6x higher thermal conductivity (170 W/mK vs. 30 W/mK for alumina), enabling efficient heat dissipation in high-density circuits. Its thermal expansion coefficient (4~6×10⁻⁶/K) closely matches silicon (3×10⁻⁶/K), reducing stress-induced failures in semiconductor packaging. Additionally, AlN’s non-toxicity and volume resistivity (>1*1013 Ω·cm) make it safer and more reliable for power modules and LED systems.

In semiconductor etching and thin-film deposition processes, heating plates need to provide rapid, uniform, and stable heating to wafers in vacuum, plasma, and corrosive gas environments. Aluminum nitride ceramics offer irreplaceable advantages in this application: 1) Ultra-high thermal conductivity: enabling rapid heating and cooling, improving process efficiency; 2) Excellent temperature uniformity: ensuring consistent processing across the entire wafer, improving yield; 3) Outstanding plasma resistance: exhibiting good durability and long lifespan in halogen plasma; 4) Thermal expansion matching: having a thermal expansion coefficient close to that of silicon wafers, reducing wafer warping or breakage caused by thermal stress. Therefore, it is the material of choice for advanced processes (such as 7nm and 14nm).

AlN’s low dielectric loss (tanδ <0.001 at 1 MHz) and high thermal stability minimize signal attenuation in high-frequency 5G circuits. Its ability to dissipate heat efficiently prevents overheating in RF amplifiers, improving signal integrity and device lifespan. For instance, AlN substrates in GaN-based RF devices reduce junction temperatures by 20%, enhancing power output by 15%.

Yes. AlN’s non-porous structure and chemical inertness allow it to withstand corrosive agents like sulfuric acid (pH <1) and molten aluminum. In chemical reactors, AlN thermocouple tubes show <0.1% weight loss after 5 years of exposure. Its resistance to oxidation at 1,200°C also makes it ideal for aerospace engine components.

Aluminum nitride ceramics can be machined (such as cutting and drilling), but special processes are required, such as diamond wheel cutting, laser processing or ultrasonic drilling, to avoid edge collapse. Ordinary drill bits cannot be used for processing, and diamond tools are recommended. The cost of precision processing of aluminum nitride ceramics is relatively high, and it is best to achieve near-net shape without additional processing.