What Are Advanced Ceramic Materials

Advanced ceramics, also known as technical ceramics or engineering ceramics, are high-purity ceramic materials manufactured with controlled compositions and microstructures. Unlike traditional ceramics, advanced ceramics are optimized for functional and structural performance rather than decorative use.

They are widely applied in environments requiring:

-

High-temperature resistance

-

Mechanical strength and wear resistance

-

Electrical insulation or conductivity control

-

Chemical inertness

-

Dimensional stability

Advanced Ceramic Materials Overview

Advanced ceramic materials are engineered inorganic, non-metallic solids designed to perform under extreme mechanical, thermal, electrical, and chemical conditions. Compared with metals and polymers, ceramics offer superior hardness, wear resistance, heat stability, and electrical insulation, making them essential in aerospace, electronics, energy, semiconductor, and industrial manufacturing.

This materials hub provides a comprehensive overview of the most commonly used advanced ceramic materials, their key properties, typical applications, and guidance on how to select the right ceramic material for your specific engineering needs.

Advanced ceramics VS Traditional ceramics

| Items | Traditional Ceramics | Advanced Ceramics |

| Raw Materials | Natural minerals, used directly without treatment | Highly selected raw materials, artificial synthesis |

| Structure | The microstructure is coarse, uneven, and porous | Uniform and fine microstructure |

| Preparation Process | Low sintering temperature, no processing required after sintering | The sintering temperature is high and processing is required after sintering |

| Product Performance | Limited to daily life and construction use | Excellent physical, chemical and other properties, industrial fields |

The commonly ceramic forming processes for technical ceramics include isostatic pressing, dry pressing, tape casting,hot die casting, extrusion forming, injection molding,slip casting, etc. The initial blank is sintered to densify the internal structure. In order to achieve the product dimensional accuracy required by customers, diamond tools are sometimes required for grinding.

Common Advanced Ceramic Materials Overview

Below is an overview of the most widely used ceramic materials in industrial and engineering applications.

-

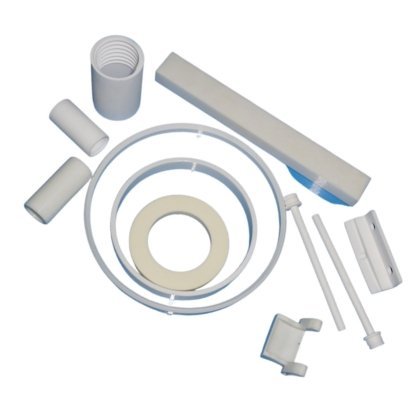

Alumina Ceramic Parts

Alumina Ceramic PartsAlumina ceramic is one of the most widely used technical ceramics due to its high hardness, excellent wear resistance, good electrical insulation, and cost-effectiveness.

-

Zirconia Ceramic Parts

Zirconia Ceramic PartsZirconia ceramic is known for its exceptional fracture toughness and impact resistance compared with other ceramics. Its transformation toughening mechanism makes it suitable for load-bearing applications.

-

AlN Ceramic Parts

AlN Ceramic PartsAluminum nitride ceramic is a high-thermal-conductivity ceramic material known for its excellent heat dissipation combined with electrical insulation. It is especially suitable for electronic and thermal management applications.

-

Silicon Nitride Ceramic Rollers

Silicon Nitride Ceramic RollersSilicon nitride ceramic provides outstanding thermal shock resistance, high mechanical strength, and excellent chemical stability at elevated temperatures.

-

Boron Nitride Ceramic Parts

Boron Nitride Ceramic PartsBoron nitride ceramic features excellent self-lubricating properties, high thermal conductivity, and electrical insulation. It is easy to machine compared with most ceramics.

-

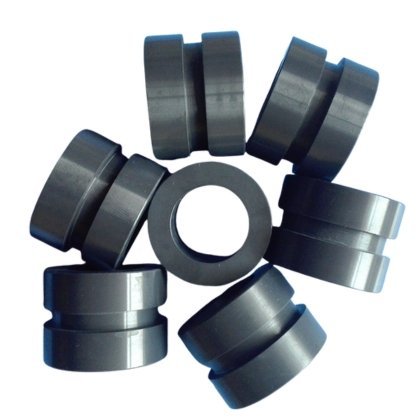

Silicon Carbide Ceramic Flange

Silicon Carbide Ceramic FlangeSilicon carbide ceramic is an ultra-hard, high-strength ceramic material offering exceptional wear resistance, high-temperature stability, and outstanding thermal conductivity.

Why Choose Ceramic Materials for Industrial Applications?

Ceramic materials are chosen when conventional materials such as metals or plastics fail to meet performance requirements.

Key advantages of advanced ceramics include:

-

High hardness and abrasion resistance

-

Excellent thermal stability and low thermal expansion

-

Superior corrosion and oxidation resistance

-

Electrical insulation at high temperatures

-

Long service life under harsh conditions

These characteristics make ceramics ideal for precision components, high-temperature fixtures, and wear-critical parts.

Key Properties of Advanced Ceramics

Material selection always involves balancing performance requirements with cost and manufacturability.When evaluating ceramic materials, engineers typically consider the following performance parameters:

hardness, flexural strength, fracture toughness.

thermal conductivity, thermal shock resistance, maximum service temperature.

dielectric strength, electrical insulation.

corrosion resistance, chemical inertness.

machinability, achievable tolerances, surface finish.

Advanced Ceramic Materials Property Comparison

While exact values vary by grade and processing method, the table below provides a general comparison to support material selection:

| Material | Strength | Toughness | Thermal Stability | Wear Resistance | Electrical Properties |

|---|---|---|---|---|---|

| Alumina | High | Medium | High | High | Excellent insulation |

| Zirconia | Very High | Very High | Medium–High | High | Good insulation |

| ZTA | High | High | High | Very High | Good insulation |

| Silicon Carbide | Very High | Medium | Very High | Extremely High | Semiconductor |

| Silicon Nitride | High | High | Very High | High | Insulating |

| Aluminum Nitride | Medium | Medium | High | Medium | High thermal conductivity + insulation |

| Boron Nitride | Low–Medium | Low | Very High | Low | Excellent insulation |

| Cordierite | Low | Low | High | Low | Good insulation |

| Mullite | Medium | Medium | Very High | Medium | Good insulation |

How to Choose the Right Ceramic Material

Selecting the right advanced ceramic material depends on operating conditions and performance priorities:

-

High wear resistance: Alumina, ZTA, Silicon Carbide

-

High fracture toughness: Zirconia, ZTA, Silicon Nitride

-

High-temperature stability: Silicon Carbide, Mullite, Silicon Nitride

-

Thermal shock resistance: Silicon Nitride, Cordierite

-

Thermal conductivity + electrical insulation: Aluminum Nitride

-

Self-lubrication & easy machining: Boron Nitride

For complex applications, material selection often involves balancing performance, cost, manufacturability, and service life.

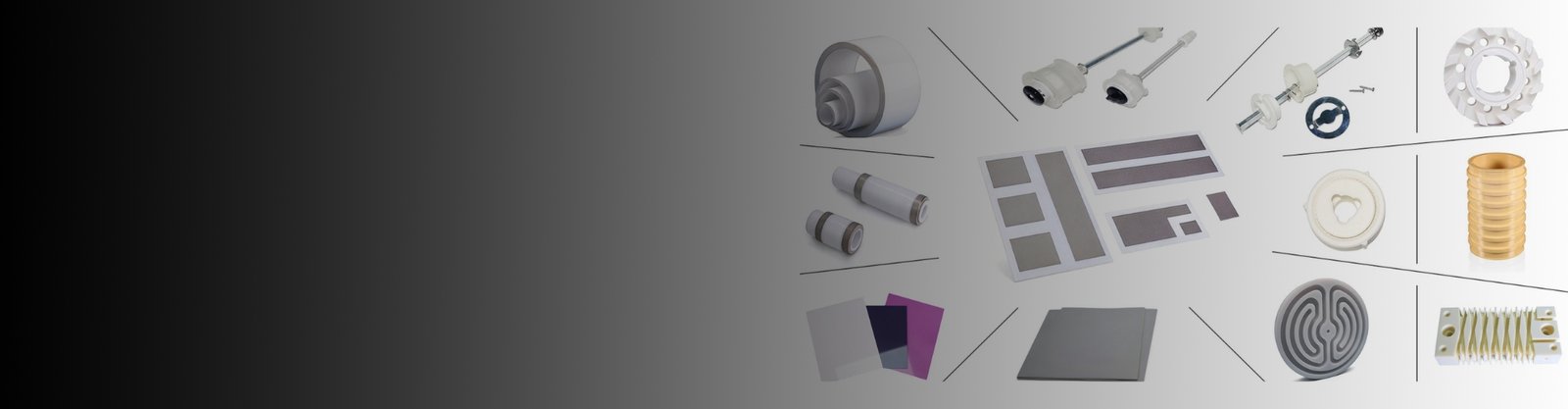

Custom Advanced Ceramic Manufacturing

Advanced ceramic components can be customized to meet specific application requirements, including:

-

Custom sizes and complex geometries

-

Precision machining with tight tolerances

-

Surface finishing such as polishing or coating

-

Material composition optimization for targeted performance

Our ceramic materials and components are widely supplied for industrial, electronic, energy, and medical applications worldwide.

Manufacturing Excellence

Advanced ceramics are produced by using different ceramic forming methods, then sintering for near-theoretical density and jprecision grinding for micron-level precision.

| Process parameters | Minimum slot width (mm) | hole machining accuracy (mm) | Roughness Ra (μm) | Parallelism (mm) | Linear dimension accuracy (mm) | Warpage (mm) | Roundness (mm) |

| Accuracy | 0.2 | ±0.005 | 0.01~0.2 | 0.001/100 | ±0.002 | 0.005/100 | ±0.001 |

Get Expert Support for Ceramic Material Selection

Selecting the right ceramic material is critical to product performance and service life. Our technical team supports material selection, design optimization, and custom manufacturing for a wide range of advanced ceramic applications.

Contact us to discuss your ceramic material requirements or request a technical consultation.

Advanced ceramics are engineered ceramic materials with controlled composition and microstructure, designed for high-performance industrial and engineering applications.

Ceramics offer higher hardness, better wear resistance, and superior high-temperature stability than metals, but generally have lower ductility.

Alumina and ZTA ceramics are commonly used for wear-resistant applications, depending on impact and toughness requirements.

Yes. Most advanced ceramic materials can be customized in terms of composition, shape, and machining tolerance based on application needs.