Do you know why 85% of the world’s industrial abrasives and grinding tools are made of aluminum oxide (Alumina)? From extreme wear resistance to thermal stability, alumina offers seven key advantages that directly boost your tool’s lifespan, efficiency, and performance. Ready to engineer a smarter solution?

Seven Core Advantages

1. The perfect balance: superb hardness that lasts

Aluminum oxide has a Mohs hardness of 9, second only to diamond in nature. It effectively cuts a variety of steels and alloys. Furthermore, it exhibits exceptional toughness during cutting, capable of withstanding the pressure and impact of grinding.

2. Unmatched Versatility, Unbeatable Value

Aluminum oxide abrasives have an unparalleled cost-effectiveness ratio. Compared to silicon carbide, the production cost of alumina is only 16% to 25%; however, it can be used in cutting materials ranging from carbon steel and alloy steel to cast iron, as well as wood and plastic.

3. Multifunctional particle morphology

Alumina abrasives come in various shapes, produced through processes such as melting and sintering, which create particles with round, block, and sharp angles, meeting a range of needs from heavy-duty grinding to fine polishing.

4. Look beyond the price tag: Real savings in total cost

When evaluating abrasive tooling costs, do you focus solely on the unit price, or are you more concerned with the total cost? Aluminum oxide abrasive tools are an ideal choice because their excellent balance of hardness and toughness translates into longer tool life, resulting in less frequent replacement and less downtime. Furthermore, their consistent performance reduces scrap and rework costs associated with tooling issues.

5. Less time, more parts: How alumina fuels your productivity

Aluminum oxide has strong inherent self-sharpening properties, meaning it will not dull with use like ordinary abrasive tools. It can continuously maintain an efficient cutting rate, thus shortening the processing time of a single part. At the same time, due to the high reliability, it allows for more radical or more stable process parameter settings, optimizing the overall production rhythm.

6. Highly consistent quality in every batch

As products manufactured using a mature process, aluminum oxide abrasives ensure consistent performance across every batch, which is crucial for fully automated production lines. The stability of abrasive quality is directly associated with the consistency of final product quality and the repeatability of the process.

7. Operational safety and environmental protection features

Alumina is highly chemically inert and non-toxic. At room temperature, it does not react with strong acids or bases, except for HF. It complies with international environmental, food, and occupational health standards, including OSHA, FDA, and REACH. Choosing alumina abrasive not only ensures optimal performance but also demonstrates a strong commitment to employee health, environmental responsibility, and business compliance.

Applications

Aluminum oxide exists in various forms within various wear-resistant tools. Generally speaking, it can be categorized into three main groups: a key functional or structural component, a surface treatment/coating, and a grinding and polishing material.

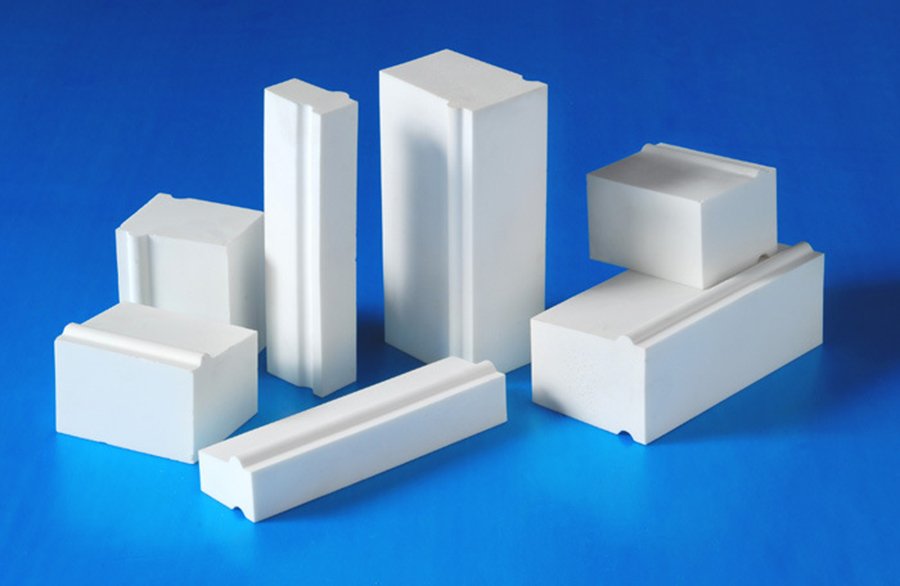

1. The body or key components of the tool

In this form, alumina appears as ceramic parts, taking advantage of its high hardness, high wear resistance, high-temperature resistance, and insulating properties. These include cutting tools, wear-resistant parts, grinding media, precision measuring tools, electronic insulation tools, and welding tools.

2. Surface coating or treatment layer of the tool

Aluminum oxide is used as a thin film on tools, usually carbide tools. It is chosen for its chemical resistance and heat-insulating qualities. Applications include cutting tool coatings, such as CVD (chemical vapor deposition) aluminum oxide coatings, and surface hardening treatments, such as anodizing aluminum oxide coatings.

3. Grinding and polishing materials

Aluminum oxide is manufactured into particles of various sizes and utilized as “micro cutting edges”; typical applications include grinding wheels, sandpaper, grinding stones, and grinding agents.

Conclusions

Choosing alumina for your abrasion-resistant tools isn’t just about selecting a material; it’s about partnering with a reliable, efficient, and cost-effective technology provider. It can help you improve productivity, control costs, and ensure quality and safety. Your challenges are unique. Schedule a free technical consultation today to discuss your specific needs with our application engineers and receive a customized solution.