Introduction

In heavy industries such as mining, power generation, cement, and metallurgy, equipment wear is the number one enemy leading to downtime, decreased efficiency, and soaring costs. When seeking advanced ceramic solutions, you may be confused about how to choose between alumina and silicon carbide. Should you prioritize ultimate performance or consider the overall cost of the project?

In fact, excellent selection is not about finding the “better” material, but about finding the “most suitable” solution. This article will guide you beyond simple performance parameters, helping you make the best trade-off between performance, cost, and operating conditions.

Understanding Alumina and Silicon Carbide

Before delving into a detailed comparison, we must first understand the fundamental characteristics of these two materials.

Alumina Ceramics: The Durable “Economy Guardian”

Alumina ceramics primarily use industrial alumina of varying purities as their raw material, featuring mature technology and stable manufacturing processes. Purity levels (such as 75%, 95%, 99%, 99.5%, etc.) directly influence their final performance and price, forming a comprehensive product series. It is renowned for its outstanding cost-effectiveness, reliable wear resistance, excellent chemical stability, and superior electrical insulation properties. In industrial wear-resistant applications, it functions like a versatile, specialized main force. It can deploy the most suitable unit (purity grade) according to battlefield (operating condition) requirements, winning the vast majority of routine battles at minimal cost.

Silicon Carbide Ceramics: The Ultimate Performance “Special Forces”

Silicon carbide ceramics, with their strong covalent bond bonding, have set a performance benchmark in the field of industrial wear resistance. Their core advantages directly translate into extremely long component life and extremely low wear rate. It exhibits extremely high hardness, top-tier wear resistance, and also possesses excellent thermal conductivity and outstanding high-temperature strength. These characteristics make it the ultimate solution for extreme wear conditions. It’s like a special forces unit built for tackling tough challenges. Although it’s more expensive, it exists specifically to conquer the most demanding wear-resistant battles that would cause ordinary materials to fail quickly.

A Deep Comparison of Key Properties Between Alumina and Silicon Carbide

To conduct a more in-depth comparison of the wear resistance of alumina and silicon carbide, we first need to examine the following key performance indicators.

| Performance Indicator | Alumina Ceramics | Silicon Carbide Ceramics | Selection Analysis |

| Hardness | High | Extremely high | Silicon carbide is better suited for handling sharp, high-speed cutting wear. |

| Wear Resistance | Good, meets most needs | Excellent, lifespan several times that of alumina. | Does your operating environment truly require such an extreme service life? |

| Toughness | Average | Slightly better, but still brittle. | Under high-impact conditions, we need to evaluate the structural design for both materials. |

| Density | Higher | Lower | Silicon carbide has advantages in components that require lightweighting. |

| Thermal Conductivity | Low | Very high | Key difference! Silicon carbide is the preferred choice for heat dissipation applications. |

| Cost | Affordable | Relatively expensive | Core decision factor! Alumina is typically only 1/3 to 1/2 the price of silicon carbide. |

Looking at the data alone, silicon carbide appears to have the upper hand in every aspect. But the real choice lies in weighing the pros and cons. This comparison table tells us that the premium paid for silicon carbide is in exchange for its top-tier performance. However, if your operating conditions don’t require this extreme performance, then every penny spent is a waste of money.

Alumina vs. Silicon Carbide: How to Choose? Four Key Decision Factors

So, how do you determine whether your operating conditions require alumina or silicon carbide? Please evaluate based on the following four factors.

Degree of Operating Harshness

Choose Alumina: For moderately abrasive scenarios such as low-to-medium speed material conveying, ordinary powder grinding, and slurry washing, alumina ceramics already provide a lifespan several times longer than metals, which is perfectly adequate.

Consider Silicon Carbide: Only in extreme abrasive scenarios, such as high-speed airflow sandblasting, precision polishing, and strong washing with sharp particles, is a silicon carbide solution truly necessary.

Cost Considerations

Choose Alumina: If your project is budget-sensitive or has strict requirements for initial procurement costs, alumina is your wisest and most economical choice. It resolves the vast majority of wear issues with minimal investment.

Consider Silicon Carbide: If your budget is ample and your factory downtime costs are extremely high, and you are willing to pay a higher upfront investment for longer service life and fewer shutdowns, then evaluate the long-term value of silicon carbide.

Are there any special performance requirements?

Choose alumina: If your requirements are purely for wear resistance and corrosion resistance, alumina is sufficient.

Must choose silicon carbide: If your components require both excellent thermal conductivity (e.g., furnace rolls, heat exchanger components) or the ability to maintain strength at ultra-high temperatures, silicon carbide is your only choice.

Delivery Time

Choose Alumina: Alumina ceramics have a mature process, shorter production cycles, and stronger processing capabilities for complex, irregularly shaped parts, allowing for faster response to your urgent needs.

Consider Silicon Carbide: Silicon carbide is more difficult to sinter and process, typically resulting in longer delivery times. It is more suitable for relatively standard-shaped components.

Why is Alumina the Market Leader?

Based on the above decision-making approach, it is not difficult to see that for the vast majority of companies, choosing alumina means achieving the best balance between performance, cost, and risk.

1. Exceptional cost-effectiveness: In 80% of common industrial wear applications, alumina ceramics deliver significantly longer service life than metals and maintain stable performance for thousands of hours. Achieving fully adequate solutions at one-third the cost is the most rational business decision.

2. Unparalleled reliability: The manufacturing process for alumina has been proven over decades, with stable performance and minimal batch-to-batch variation. This eliminates the unknown risks that new materials may bring.

3. High flexibility and customizability: From liners and bricks to pipes and nozzles, alumina can be made into a variety of complex shapes to flexibly adapt to your existing equipment. This adaptability forms the solid foundation for its status as the market’s leading choice.

When is Silicon Carbide the Preferred Choice?

Of course, we do not deny the value of silicon carbide. In the following mission-critical scenarios, it is almost the only choice.

1. Power plant desulfurization system: The sealing rings and linings of the circulating pumps need to withstand both strong corrosion and extreme wear.

2. Steel and ceramics industries: High-temperature furnace rolls must withstand both extreme heat and heavy loads, requiring excellent thermal conductivity.

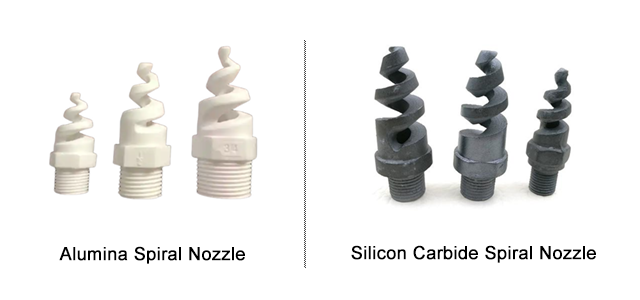

3. Demanding nozzle applications: Requiring resistance to high-speed abrasion from hard particles while maximizing service life.

In these fields, silicon carbide delivers increased efficiency and reduced downtime, making its high initial cost worthwhile.

Conclusion

Back to the initial question: alumina vs. silicon carbide: how to choose? The key to the answer lies in “matching.” We hope this comprehensive wear resistance comparison guide will provide you with a clear path forward.

If you’re still unsure which material best suits your equipment, please contact our ceramic experts immediately. Provide your operating parameters, and we will offer you free selection advice and customized solutions!

FAQs

Q1: What is the main difference between alumina and silicon carbide ceramics?

A: The most crucial differences lie in hardness, wear resistance, and cost. Silicon carbide is significantly superior to alumina in hardness and wear resistance, but its manufacturing cost is also several times higher. Alumina, on the other hand, is the preferred choice for most working conditions due to its extremely high cost-effectiveness and reliable performance.

Q2: Which is harder, alumina ceramics or silicon carbide ceramics?

A: In terms of absolute hardness, silicon carbide ceramics are harder. Their covalent bond structure gives them a higher upper limit to hardness, making them particularly advantageous when facing extreme wear from sharp, hard particles. However, practical selection requires comprehensive evaluation: Alumina ceramics (especially those with over 95% purity) already meet the hardness requirements for over 80% of industrial wear-resistant applications while offering significant cost advantages. Unless operating conditions are exceptionally severe, choosing alumina is often the more economical and pragmatic choice.

Q3: Why is silicon carbide ceramic more expensive than alumina ceramic?

A: The higher price of silicon carbide ceramics is mainly due to two core factors:

1. High raw material cost: The required purity of silicon carbide powder is extremely high, and the preparation process consumes a huge amount of energy.

2. Complex manufacturing process: Sintering temperatures must exceed 2100℃(compared to approx. 1600℃for alumina), requiring specialized equipment and a strictly controlled atmosphere, resulting in a significant increase in production costs.

These process characteristics, while contributing to the superior performance of silicon carbide, also directly drive up its manufacturing costs.

Q4: When should I choose alumina ceramics over silicon carbide?

A: Alumina is the wiser choice in the following situations:

1. In applications with moderate wear, such as general material handling.

2. When project budgets are limited and initial costs are critical.

3. When rapid delivery is required, alumina offers shorter production cycles.

4. When parts have complex shapes, alumina provides better machinability.

Q5: Are there any applications where I must use silicon carbide ceramics?

A: Yes. You should consider silicon carbide when your application meets all of the following conditions:

1. Extreme wear: Such as high-speed gas streams carrying hard particles.

2. High temperature and thermal conductivity requirements: Such as high-temperature furnace rolls and heat exchanger components.

3. Extremely long maintenance-free life is a critical requirement, and a sufficient budget is available.

Q6: What is the maximum temperature alumina ceramics can withstand? What about silicon carbide?

A: For long-term use in air, silicon carbide generally exhibits better high-temperature resistance. However, specific values depend on the material grade.

1. For the most commonly used 95% alumina: The maximum long-term service temperature in air is approx. 1500℃.

2. For pressureless sintering silicon carbide: The maximum long-term service temperature in air is approx. 1650℃. Under an inert atmosphere, its temperature resistance can exceed 1800℃.

Key suggestion: If your operating temperature consistently exceeds 1500℃, or if you require both excellent high-temperature strength and thermal conductivity, silicon carbide is the more reliable choice.

Q7: Which one is better at resisting acid and alkali corrosion: alumina or silicon carbide?

A: For strong acids, both are suitable. However, for applications involving strong alkalis or extreme chemical environments, silicon carbide is a more reliable choice.

Alumina ceramics: Possess excellent acid resistance, exhibiting good resistance to most strong acids and organic acids. However, its corrosion resistance in high-temperature strong alkaline solutions is relatively weak.

Silicon carbide ceramics: Possess comprehensive chemical inertness, with outstanding acid and alkali resistance. Especially when dealing with extreme conditions such as high-temperature strong acids, strong alkalis, and molten salts, it performs more stably than alumina.

Q8: How many times longer is the lifespan of silicon carbide ceramics than that of alumina?

A: This is highly dependent on specific operating conditions. Under mild wear, the difference may not be significant. However, in extremely harsh wear environments, silicon carbide can achieve a service life 3 to 5 times longer than alumina—or even more—thereby offsetting its higher initial cost.

Q9: How to calculate the total lifecycle cost (TCO) of alumina and silicon carbide?

A: Total lifecycle cost = (Initial purchase cost + Installation cost + Replacement frequency * Downtime cost). Although silicon carbide has a higher unit price, its total lifecycle cost may be lower than alumina if it significantly reduces replacement frequency and downtime.

Q10: Is there a difference in the difficulty of machining alumina and silicon carbide ceramics?

A: There is a significant difference. Alumina ceramics can be cut and ground using standard diamond tools, making them relatively easy to machine. Silicon carbide, however, possesses extremely high hardness, resulting in difficult and time-consuming machining processes that cause severe tool wear, further increasing its cost.

Q11: How well do alumina and silicon carbide ceramics resist thermal shock?

A: Silicon carbide exhibits significantly better thermal shock resistance than alumina. This advantage is due to its exceptionally high thermal conductivity. It enables rapid and uniform heat distribution, preventing cracks caused by excessive localized temperature differentials. Therefore, silicon carbide is the better choice for operating conditions involving rapid temperature changes.