Introduction

When you hear the word “ceramics,” images of bowls, plates, or vases are likely to immediately come to mind. These traditional ceramic products are hard, but they are also very fragile and will break if dropped. However, the zirconia ceramic we are introducing today will completely overturn your understanding. Not only does it possess astonishing hardness, but more importantly, it boasts exceptional toughness that rivals certain types of steel. So, what exactly is the secret behind this miraculous “unbreakable” ceramic? Let’s explore it together.

Hardness vs. Toughness: A Critical Difference

Before delving deeper, we first need to clarify a key concept: hardness and toughness are not the same thing.

Hardness measures a material’s resistance to scratches or indentation. For example, a diamond can scratch glass, demonstrating its high hardness.

Toughness, on the other hand, refers to a material’s ability to resist crack propagation and fracture—its capacity to absorb energy without breaking. A spring that can bend and stretch demonstrates good toughness.

Traditional ceramics are brittle precisely because of their “high hardness and low toughness.” Once a tiny crack forms on the surface, it propagates rapidly with almost no resistance, causing the material to break instantly. So how does zirconia ceramic solve this age-old problem?

Principles of Zirconia Ceramic Toughness

The answer to the above question lies in the microscopic world invisible to the naked eye. Zirconia ceramics possess a unique property—phase transformation toughening. This process is like a micro-magic trick in materials science.

Step 1: The Dormant Guardians

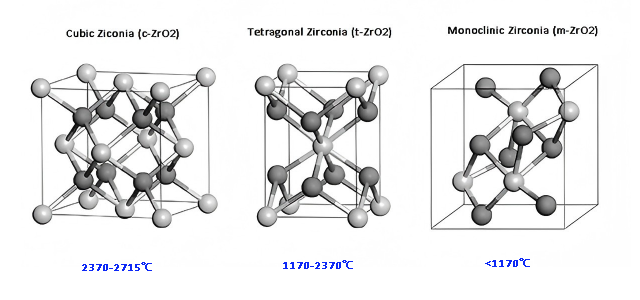

At room temperature, the internal structure of zirconia ceramics is not singular and unchanging. Through a special stabilization process, we enable most zirconia grains to exist in a metastable “tetragonal phase” form. You can imagine these grains as countless compressed springs, or heavily armored guards ready to pounce; they are highly energetic, yet stably lurking within the material.

Step 2: Crack Attack and Instant Transformation

When a material is subjected to an external impact, and a crack begins to form and attempt to propagate, a remarkable phenomenon occurs. A tremendous stress field is generated at the crack tip. This stress field acts like a bugle call, instantly activating the surrounding metastable tetragonal grains.

As a result, they quickly “transformed” into a more stable “monoclinic phase” structure. This phase transition process is accompanied by a key action: the grain volume expands slightly.

Step 3: Squeeze to Stop: How the Crack Closes

This crucial volume expansion transforms the microscopic phase transition into macroscopic crack resistance. The expanding grains exert a huge “compressive stress” on the expanding crack. You can imagine it as countless tiny wedges being driven into the sides of the crack just as it is about to split open, tightly squeezing the crack together.

This process produces two effects:

- Direct mechanical inhibition: The compressive stress effectively resists the tensile force that would cause the crack to open, forcibly preventing the crack from expanding further.

- Energy consumption: Grain phase transformation itself requires a lot of energy, which would originally be used for crack propagation, but is now successfully absorbed and dispersed.

Zirconia Ceramic Properties: A Performance Breakdown

The table below provides a visual comparison of key properties between zirconia ceramics and several common materials, clearly demonstrating its superior performance.

| Material | Fracture Toughness (MPa·m¹/²) | Flexural Strength (MPa) | Vickers Hardness (Hv) | Key Characteristics |

| Zirconia Ceramic | 6.5 – 11 | ≥750 | 1070 – 1230 | High strength, high toughness, high hardness, wear-resistant |

| Alumina Ceramic | 3 – 5 | ≥200 | ≥1380 | High hardness, high insulation, but lower strength and toughness |

| Tool Steel | ~50 | 1500 – 2500 | 700 – 900 | Excellent strength and toughness, but low hardness and susceptible to corrosion |

| Sapphire Glass | 2 – 3 | ~1000 | ~2000 | Extremely high hardness, but very brittle |

| Ordinary Glass | 0.7 – 0.8 | 30 – 90 | ~500 | Transparent, but extremely brittle |

Table analysis:

1. Exceptional comprehensive mechanical properties

As shown in the “ Flexural Strength” column, zirconia ceramic exhibits significantly higher strength than alumina ceramic and ordinary glass, comparable to sapphire glass. This explains why it can be used in structural components subjected to bending stresses.

2. A perfect combination of strength and toughness

This table now clearly demonstrates the core advantage of zirconia ceramics—it successfully integrates three properties that are typically difficult to achieve simultaneously: high strength, high toughness, and high hardness.

Tool steel is strong and tough, yet lacks sufficient hardness.

Alumina ceramics and sapphire glass boast high hardness but are brittle (poor toughness).

Zirconia ceramics achieve the optimal balance among these three properties, which is precisely why it excels in numerous demanding applications—from precision seals to artificial joints.

Zirconia Ceramic Applications

These remarkable properties of zirconia ceramic are rapidly being translated into high-performance solutions for various industrial challenges.

1. Industrial Wear Resistance and Sealing

Under extreme operating conditions, zirconia ceramic is the go-to material. For instance, in high-speed ceramic bearings running without lubrication, it operates stably at tens of thousands of revolutions per minute, achieving a service life over five times longer than traditional steel bearings. Similarly, in mechanical seal rings for chemical pumps, it withstands both corrosive strong acids and the severe abrasion from particulate media while maintaining a zero-leakage seal, ensuring continuous and safe operation.

2. Energy and Sensor Technology

Zirconia ceramic plays a critical role in multiple green technologies. As the electrolyte membrane in Solid Oxide Fuel Cells (SOFCs), it precisely conducts oxygen ions at 800°C to generate electricity efficiently. Meanwhile, at the tip of automotive oxygen sensors, it continuously monitors exhaust oxygen levels and relays signals to the engine ECU, improving fuel efficiency by over 10% and significantly reducing NOx emissions.

3. Consumer Electronics and Smart Wearables

In the consumer domain, zirconia ceramic is redefining the essence of premium quality. In the antenna window area of 5G smartphones, it allows unimpeded signal passage where metal would cause interference. For high-end smartwatch cases, its hardness—over 8 times that of stainless steel—effectively resists daily scratches and keeps a like-new finish.

4. Precision Machined Components

Moving beyond conventional components, zirconia ceramic excels in precision machining. Zirconia Toughened Alumina (ZTA) ceramic cutting tools provide 3-5 times the service life of conventional carbide tools in high-speed finishing of cast iron, achieving “turning as a replacement for grinding.” Additionally, its combination of high hardness and low weight makes it suitable for precision instrument guides and advanced ballistic armor.

Conclusion

From uncovering the microscopic secrets of “phase transformation toughening” to envisioning its vast potential in industry, energy, and smart technology, we can see that zirconia ceramic is playing an increasingly vital role in modern industry.

If you are looking for reliable advanced ceramic material solutions for your project or product, our professional engineering team is here to support you. Please feel free to contact us for more information.

FAQs

Q1: What exactly is the principle behind the toughness of zirconia ceramics?

A: Simply put, it comes from a unique mechanism called “phase transformation toughening”. When a crack attempts to propagate in a material, the stress at the crack tip triggers the surrounding zirconia grains to instantly transform from one crystalline phase (tetragonal phase) to another (monoclinic phase). This transformation is accompanied by volume expansion, which compresses the crack and effectively prevents it from propagating further. This is like having millions of tiny “self-healing switches” inside the material that automatically activate when damaged.

Q2: Which ceramic is tougher: zirconia or alumina?

A: Undoubtedly, zirconia ceramics possess significantly higher toughness than alumina ceramics. Data shows that the fracture toughness of zirconia is typically two to three times greater than that of alumina. This means that zirconia ceramics are more resistant to fracture under impact or bending forces, while alumina ceramics are more brittle.

Therefore, zirconia is the superior choice for applications requiring impact and drop resistance (such as smartphone back panels and surgical instruments); while alumina ceramics, offering better cost-effectiveness, are widely used in applications where only extremely high hardness and wear resistance are needed, and toughness requirements are not extreme (such as wear-resistant liners and electronic substrates).

Q3: Is zirconia ceramic so hard that it’s difficult to machine?

A: Yes, you’re right. The extreme hardness of zirconia ceramic makes it a challenging material to machine. Traditional cutting methods are almost impossible, and specialized machining techniques such as diamond grinding, laser cutting, and CNC polishing are required. This is precisely why sourcing precision ceramic components from a professional manufacturer like JINGHUI is so important—we possess the specialized equipment and process knowledge to ensure that the final product achieves perfect dimensional accuracy and surface finish.

Q4:What are the advantages and disadvantages of zirconia ceramics compared to silicon carbide ceramics?

A:This is a highly specialized question. Both are excellent advanced ceramics, but their properties differ:

Zirconia ceramics’ core advantage lies in their extremely high fracture toughness and flexural strength, giving them superior resistance to mechanical impact at room temperature, excellent wear resistance, and a low coefficient of friction. They also exhibit good biocompatibility.

Silicon carbide ceramics‘ core advantage lies in their extremely high thermal conductivity, high-temperature strength, and excellent thermal stability above 1300°C. Their thermal shock resistance is far superior to that of zirconia ceramics.

Therefore, the key to selection lies in the application scenario:

If you require wear-resistant and impact-resistant components (such as bearings, cutting tools, and dental implants) and intend to use them at room temperature or in medium to low temperatures, zirconia ceramics are an ideal choice.

If your application involves high temperatures, rapid thermal cycling, or requires good heat dissipation (such as kiln furniture, burners, and heat exchanger components), then silicon carbide ceramics are more suitable.

Q5: Zirconia ceramics have good impact resistance, but do they also have good thermal shock resistance?

A: No, these are two different concepts; zirconia ceramics exhibit very different performance in this regard.

Impact resistance (mechanical properties): This refers to the ability to resist external impacts or shocks without breaking. Zirconia ceramics perform exceptionally well in this regard, thanks to their “phase transformation toughening” mechanism.

Thermal shock resistance (thermal properties): This refers to the ability to resist thermal stress caused by rapid temperature changes, which can lead to cracking or breakage. Zirconia ceramics perform relatively poorly in this aspect, mainly due to their low thermal conductivity and high coefficient of thermal expansion. Excessive temperature differences between the surface and interior can generate thermal stress that easily leads to cracking. Therefore, it is generally not recommended for applications requiring the ability to withstand drastic or rapid temperature changes.

Q6: What special considerations should be taken into account when designing zirconia ceramic components?

A: Yes, due to its ceramic properties, the following design considerations are necessary: avoid sharp edges and corners, and use rounded corners to distribute stress; consider its low thermal conductivity and pay attention to thermal stress in thermal cycling applications; understand its high modulus of elasticity, and design tolerances differently from those for metals. We strongly recommend communicating with our engineers early in the design process to obtain the best solution.

Q7: Zirconia ceramic parts are usually more expensive than metal parts. Where does their value lie?

A: Its value lies in its longer service life and lower overall cost. A zirconia ceramic seal or bearing can have a lifespan that is several times or even tens of times longer than that of a steel one, which greatly reduces the frequency of downtime for replacement and maintenance costs. At the same time, its corrosion resistance avoids pollution and loss caused by rust, and can significantly improve the performance and reliability of the final product in specific applications. This is an investment focused on long-term returns.

Q8: Can we provide drawings to customize zirconia ceramic parts?

A: Of course! One of JINGHUI’s core businesses is providing customized advanced ceramic parts solutions for our clients. From drawing evaluation and material selection to precision machining and quality inspection, we offer a one-stop service. Feel free to submit an inquiry, and our engineering team will contact you as soon as possible.