Introduction

In the chemical, pharmaceutical, or water treatment industries, are you facing this dilemma: expensive metal pressure sensors frequently fail in corrosive media? Inaccurate measurements, component replacements, and downtime risks—these issues not only cost money but also pose safety risks. To find a breakthrough, we must turn our attention to the first line of defense—the isolation diaphragm—that directly interacts with the media. When metal is no longer sufficient, ceramic diaphragms, a material with inherent corrosion resistance, are becoming the inevitable choice for high-end sensors. Among many engineered ceramic materials, alumina ceramics, with their superior comprehensive properties, have become the ideal solution for addressing the aforementioned industry challenges.

Why Alumina Ceramics?

Compared to metal materials, alumina ceramics offer irreplaceable advantages in corrosion-resistant pressure sensors.

1. Extreme corrosion resistance and chemical inertness

High-purity (e.g., over 99%) alumina ceramics are extremely resistant to most strong acids (such as HCI, H2SO4, and HNO3), strong bases, and organic solvents. Their stable crystal structure makes them virtually unreactive with these media, fundamentally eliminating the problems of diaphragm perforation, thinning, or the formation of a passive film on the surface due to corrosion, which can cause signal drift. This means that the sensor’s service life in corrosive environments is exponentially extended, significantly reducing maintenance costs.

2. Extraordinary hardness and wear resistance

Alumina ceramics have a Mohs hardness of 9, second only to diamond. This property allows them to easily withstand the erosion and abrasion of suspended solid particles in fluids, making them particularly suitable for applications such as mining, slurry transportation, and water treatment, effectively preventing premature failure due to diaphragm wear.

3. Excellent electrical insulation

As an excellent electrical insulator, the alumina ceramic diaphragm perfectly isolates the measured medium from the sensor’s internal electrical components, such as strain gauges and capacitor plates. This not only ensures a pure and stable measurement signal but also eliminates the risk of electrochemical corrosion, providing additional safety for the entire measurement system.

4. Good thermal stability

Alumina ceramics have a low coefficient of thermal expansion, maintaining dimensional stability and mechanical strength over a wide temperature range (-200℃ to +500℃ and above), adapting to the temperature fluctuations common in process industries.

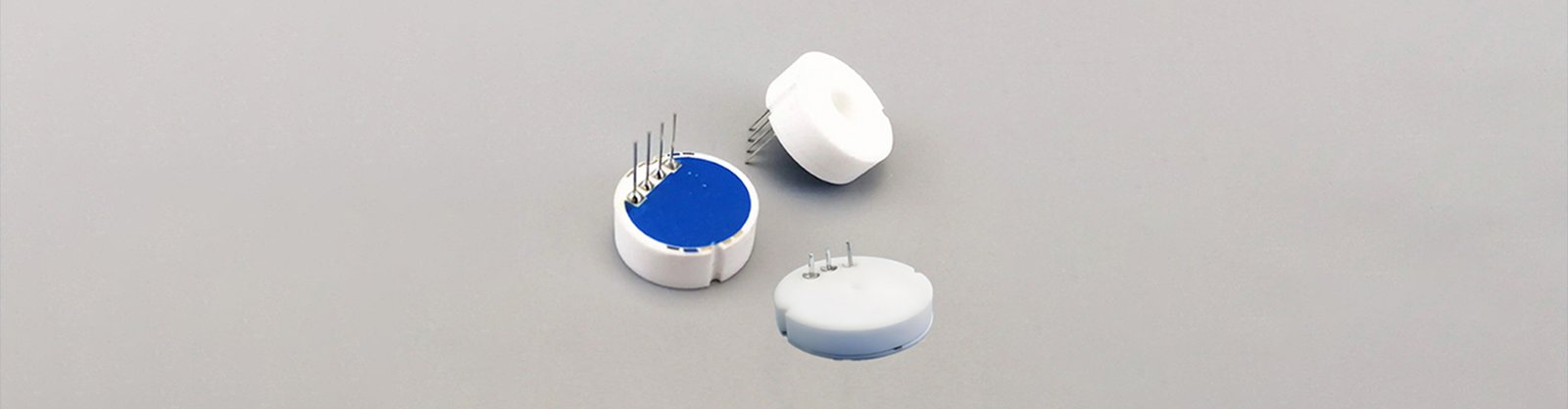

How Ceramic Diaphragm Pressure Sensors Work

Ceramic diaphragm pressure sensors typically utilize a “ceramic-metal brazing” or “all-ceramic” structure. The core component is a precision-machined, high-quality ceramic diaphragm. When pressure acts on the diaphragm, it deforms minutely. This deformation is transmitted via a transmission medium such as silicone oil to the sensor’s internal sensitive elements (such as thin-film strain gauges), which are then converted into a precise electrical output signal. The flatness, uniformity, and long-term stability of the ceramic diaphragm are crucial to the sensor’s accuracy and reliability.

Main Applications of Ceramic Pressure Sensors

- Chemical industry: Reactor pressure monitoring, pressure protection of corrosive raw material/product delivery pumps.

- Pharmaceuticals and bioengineering: Sterile reactors and piping systems ensure the purity of the media.

- Food and beverage: CIP (cleaning in place) systems and pressure measurement points with high hygiene requirements.

- Water treatment and environmental protection: dosing system, sewage discharge pressure monitoring, resistance to corrosion from residual chlorine and flocculants.

Conclusion

Ceramic diaphragms, with their exceptional corrosion resistance and long lifespan, are becoming a key choice for high-end, corrosion-resistant pressure sensors. Their performance relies heavily on precision machining and reliable metallization. As a professional partner, JINGHUI specializes in providing high-performance, ready-to-install ceramic diaphragms. For more technical details or to discuss custom requirements, please feel free to contact us.

FAQs

Q1: What is the most significant advantage of ceramic diaphragms compared to metal diaphragms?

A: The core advantage is its inherent corrosion resistance. Metal diaphragms (such as 316L) can undergo electrochemical corrosion with strong acids and bases, while ceramic diaphragms like high-purity alumina ceramics are inert and virtually unreactive with all chemicals. This fundamentally eliminates problems such as corrosion perforation and signal drift caused by diaphragm thinning, extending their lifespan exponentially.

Q2: Is alumina ceramic sensitive? How accurate is its pressure measurement?

A: This is a common misconception. The alumina ceramic diaphragm senses pressure through precise micro-deformation. Its high hardness ensures deformation remains well within the elastic range, with no plastic deformation, resulting in excellent repeatability and linearity. Combined with internal strain gauges or capacitive sensing technology, it is capable of achieving highly accurate and stable pressure measurement.

Q3: Is alumina ceramic brittle? Is it prone to cracking?

A: Ceramics are brittle compared to bendable metals. The thickness of the ceramic diaphragm is carefully calculated in the pressure sensor design, ensuring compressive strength far exceeding normal operating pressures. As long as mechanical shock or pressure spikes exceeding several times the measuring range are avoided, reliability remains extremely high.

Q4: Why is metallization so crucial for ceramic diaphragms?

A: The metallization layer (such as a Mo-Mn layer and a Ni layer) is essential for achieving a high-strength, airtight, and permanent seal between the ceramic and the metal housing. Without it, the ceramic cannot be reliably welded to the sensor’s metal structure. The metallized ceramic diaphragms we provide save customers the complicated metallization process and greatly simplify their manufacturing process.

Q5: Do you provide finished sensors?

A: We regret that we do not offer finished sensor products. However, we can supply the core components of sensors—alumina ceramic diaphragms or metallized ceramic diaphragms. Our robust engineering customization capabilities enable us to provide not only standard circular diaphragms but also special shapes such as elliptical or rectangular ones tailored to your sensor design. We precisely control the pattern and positioning of metallized areas.

Q6: Can ceramic pressure sensors be used in the food and pharmaceutical industries?

A: Absolutely! Ceramic pressure sensors are an ideal choice for the food and pharmaceutical industries. Their key advantages include: 1. High-purity alumina ceramics are inherently corrosion-resistant, resistant to strong acids, bases, and solvents, and have a lifespan far exceeding that of metals. 2. They offer a mirror-like finish, eliminating dead spots and easy sterilization, meeting the highest hygiene standards. 3. The material is biocompatible, ensuring process safety and eliminating contamination risks.

Q7: Do you offer ceramic diaphragms made of other materials besides alumina?

A: Yes. In addition to alumina, which offers balanced performance, we also offer zirconia ceramics for applications requiring higher toughness. We can recommend the most economical and appropriate material solution based on your specific application (e.g., impact resistance, special media).