Introduction

While people marvel at the endurance mileage and intelligent driving features of electric vehicles (EVs), few notice the unprecedented transformation of a key material within the vehicle. An automotive ceramics application transformation is quietly taking place. They have shifted from auxiliary components in internal combustion engine vehicles (ICEVs) to core component in electric vehicles. This evolution of ceramics’ role profoundly reflects the shift in the technological focus of the automotive industry.

The ICE Era — Ceramics as the “Specialist”

During this period, ceramics were like a “special tool” in an engineer’s toolbox. It was used only in specific situations and to solve specific problems. It was important, but never became a core consideration in car design.

The “Key Supporting Role” in the Engine and Exhaust System

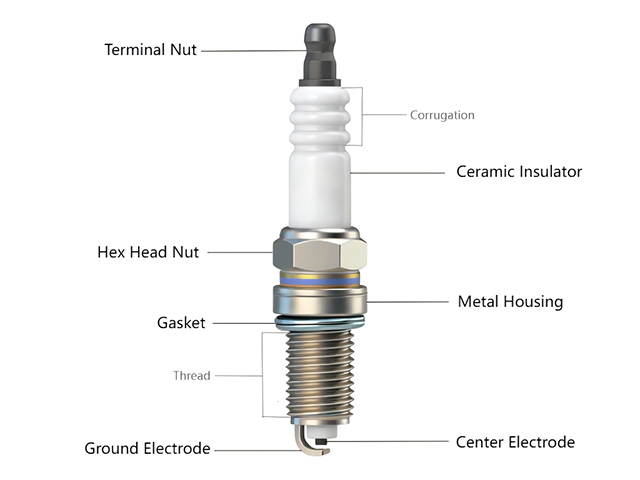

1. Spark plug insulators: This is the most classic application of alumina ceramics. Every ICEV relies on this small ceramic component to maintain stable insulation under tens of thousands of volts of voltage and temperatures exceeding a thousand degrees Celsius, ensuring proper engine ignition. More than 2 billion spark plugs are produced globally each year, almost all of which use alumina ceramics.

2. Oxygen sensor core: Zirconia ceramic-based oxygen sensors are key to precise air-fuel ratio control in modern engines. Like the engine’s “olfactory organ,” it works continuously in the harsh environment of the exhaust pipe, helping vehicles meet increasingly stringent emission standards.

3. Wear-resistant components: Components in an engine, such as valve guides, rocker arm inserts, and piston pins, are subjected to high-frequency friction. Using high-performance ceramics or ceramic coatings can significantly extend their service life.

“High-end Options” for Performance Enhancement

1. Ceramic turbocharger rotors: In pursuit of ultimate responsiveness, some high-performance vehicles use silicon nitride ceramic to manufacture their turbocharger rotors. The reduced weight and lower rotational inertia significantly improve turbo lag, but this has always been a “niche choice”.

2. High-performance brake discs: Brands like Porsche and Ferrari use brake discs made of carbon fiber reinforced silicon carbide ceramic composites as their top configuration. Their resistance to high-temperature fading is impressive, but their high price prevents them from entering the mainstream market.

Fundamental Challenges Driven by Electrification

The wave of automotive electrification has fundamentally changed the game. When voltage jumps from 12V to 400V and 800V, and when motor speed increases from 6000rpm to 20000rpm, traditional materials are reaching their physical limits.

Electric vehicles face three major material challenges:

- Insulation vs. Heat Dissipation: Power semiconductors require efficient heat dissipation, but must also be completely insulated from high-voltage circuits. Plastics and metals can each only satisfy one of these requirements.

- Speed vs. Lifespan: When the motor rotates at high speed, traditional bearings wear out more quickly. This increases the risk of electrolytic corrosion.

- Safety Vs. Energy: The battery system requires absolute insulation to prevent short circuits. It also needs high thermal conductivity to maintain uniform temperature.

It is precisely the limitations of these traditional materials that have spurred the widespread application of advanced ceramics in the electric vehicle field. Their advantage lies not in the outstanding performance of a single property, but in the perfect balance of comprehensive performance.

The EV Era — Ceramics as the “Essential Enabler”

Global electric vehicle sales are projected to exceed 20 million units by 2025, and this number is expected to more than triple by 2030. In this massive wave of electrification, advanced ceramics are quietly becoming a key factor determining technological success or failure.

The Core of Electric Vehicles

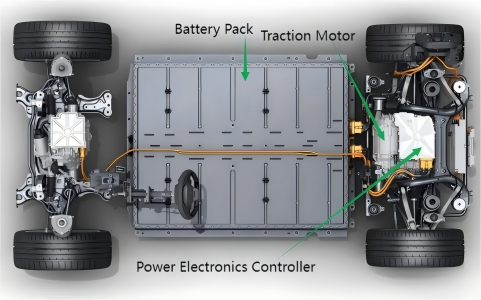

The most fundamental technological disruption of electric vehicles lies in their replacement of the engine, transmission, and mechanical drivetrain of traditional gasoline vehicles with a completely different energy conversion and control system.

This core can be summarized into the following three interdependent systems:

- High-Voltage Battery System: Stores electrical energy to power the vehicle. Its core component is the high-voltage battery pack, including Battery Cells, a Battery Management System (BMS), and a Thermal Management System.

- Electric Drive Unit (EDU): Converts electrical energy into mechanical energy to drive the vehicle. Its core components are the Traction Motor, Power Inverter, and Reducer.

- Power & Control Electronics: Precisely controls the energy output of the battery and the operation of the motor, serving as the control center for the vehicle’s energy management and drive. Its core components are the Vehicle Control Unit (VCU), Power Inverter (with IGBT/SiC power module), and Integrated Domain Controller.

Application of Ceramics in Core Electric Powertrain Systems

1. High-Voltage Connections and Insulation Components of Battery Packs: Battery packs are filled with high-voltage electricity and chemically active electrolytes, requiring absolutely reliable long-term insulation. The internal insulating pillars and high-voltage connector housings inside the battery pack are made of high-purity alumina ceramic. This provides a stable and durable insulation barrier, which is fundamental to high-voltage safety.

2. Ceramic Bearings for Traction Motors: At ultra-high speeds, steel bearings experience accelerated wear and may suffer from electro-corrosion due to current flow. Silicon nitride ceramic bearings, with a density only 41% that of steel, reduce frictional losses by more than 30% while completely eliminating the risk of electro-corrosion. This change has transformed ceramics from an “optional upgrade” into an “essential basic component.” Without it, the design of a 20,000 rpm motor would simply not be commercially viable.

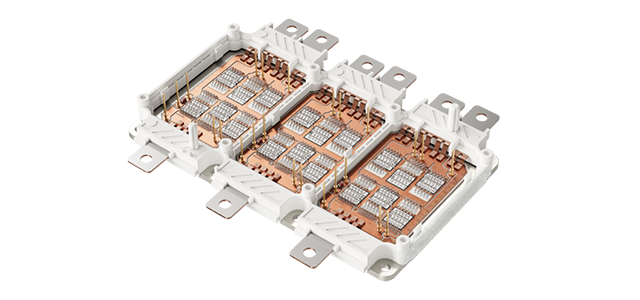

3. Power Semiconductor Module Substrates: The core function of power semiconductor (IGBT/SiC) modules is to convert the DC power from the battery into AC power required by the motor, or to perform the reverse conversion (when recovering energy). Therefore, they are present wherever high-power DC-AC conversion is needed. For example, a typical dual-motor, four-wheel-drive high-end electric vehicle requires at least four power semiconductor modules.

All power semiconductor modules face the contradiction between high-voltage insulation and efficient heat dissipation. This is precisely the fundamental reason why aluminum nitride ceramic substrates are irreplaceable. They are almost the only material currently available that can simultaneously and excellently solve both problems. Without high-performance aluminum nitride ceramic substrates, high-power-density electronic control systems are impossible, and fast charging and high performance are out of the question.

A Single Table to Understand the Automotive Ceramics Application Transformation

The evolving role of automotive ceramics profoundly reflects the shift in the technological focus of the automotive industry. The table below clearly illustrates the depth of this transformation:

| Comparison Dimension | ICEV Ceramics | EV Ceramics |

| Key Driving Force | Improving performance and reliability (e.g., reducing wear, precise control). | Resolving fundamental contradictions (e.g., high-voltage insulation and heat dissipation, high-speed wear). |

| Key Material | Alumina and zirconia are the most widely used and mature materials. | Aluminum nitride and silicon nitride are gaining prominence and becoming the focus of technological development. |

| Integration Level | Distributed and functionally specialized: Distributed across different systems such as engine, exhaust, and brake, addressing specific problems one by one (e.g., insulation, wear resistance, sensing). | Concentrated and systemically critical: Highly concentrated in the core electric powertrain systems, it has become a bottleneck material affecting performance, safety, and lifespan. |

| Design Phase | Consider during later optimization. | Must be incorporated at the initial design stage. |

| Failure Impact | May lead to performance degradation or loss of functionality. | May lead to system crashes or significant security risks. |

| Visibility | “Unsung heroes,” often imperceptible to consumers. | “Technological calling cards,” frequently used as selling points for high-performance EVs (such as ceramic bearings and carbon-ceramic brakes). |

Conclusion

When we look back at the automotive ceramics application transformation, we find that automotive ceramics have transformed from a “specialist” solving single problems in ICE vehicles to a “versatile” supporting system operation in electric vehicles. The transformation of automotive ceramics clearly tells us that materials are no longer merely tools for realizing designs, but the foundation for defining technological possibilities. For automotive engineers and manufacturers, mastering the application technology of ceramic materials is no longer an option, but a necessity for maintaining competitiveness.

FAQs

Q1: What are automotive ceramics?

A: Automotive ceramics specifically refer to advanced ceramic materials used in the automotive industry. Common types include alumina, zirconia, aluminum nitride, and silicon nitride. They possess extreme performance combinations that are difficult to achieve with traditional materials, such as high temperature resistance, high hardness, excellent wear resistance, and good electrical insulation or specific thermal conductivity.

In traditional gasoline vehicles, it mainly serves as a “specialized material” for key components (such as spark plug insulators and oxygen sensors). However, in the era of electric vehicles, it has evolved into an enabling material for core systems such as batteries, motors, and power electronics, directly impacting high-voltage safety, efficient heat dissipation, and system reliability, thus becoming a foundation for driving technological change in the automotive industry.

Q2: What are the main applications of ceramics in conventional ICE Vehicles (ICEVs)?

A: In ICE Vehicles, ceramics primarily play the role of “specialized functional components,” focusing on addressing the extreme challenges of high temperature, high pressure, and corrosion resistance in the engine and exhaust system.

1. Core Functions: Ignition, sensing, and wear resistance

2. Key Components:

1) Spark Plug Insulator (Alumina Ceramic): Withstands tens of thousands of volts and thousands of degrees Celsius, ensuring reliable ignition.

2) Oxygen Sensor Probe (Zirconia Ceramic): Monitors the oxygen content in exhaust gas, crucial for precise air-fuel ratio control and compliance with emission regulations.

3) Wear-Resistant/Heat-Resistant Components: Such as turbocharger rotors and engine wear-resistant bushings, utilizing the high temperature resistance and high hardness of ceramics to extend their lifespan.

3. Application Characteristics: Specialized functions, dispersed distribution, and cost-sensitive; the “behind-the-scenes expert” for improving performance and reliability.

Q3: What are the main applications of ceramics in electric vehicles (EVs)?

A: In EVs, ceramics have evolved into “system enablers,” directly impacting the safety, efficiency, and reliability of the core electric powertrain systems.

1. Core Functions: High-voltage insulation, efficient heat dissipation, and high-speed wear resistance

2. Key Components:

1) Vehicle Control System: Aluminum nitride ceramic substrates serve as the “heat dissipation and insulation hub” for IGBT/SiC power modules, solving the heat dissipation bottleneck of high-power chips.

2) Electric Drive Unit: Silicon nitride ceramic bearings are crucial for high-speed motors (>20,000 rpm). Their wear resistance, insulation, and lightweight construction significantly improve motor lifespan and efficiency.

3) Traction Battery Pack: Alumina ceramic insulators provide durable and reliable high-voltage isolation within the battery pack, ensuring safety.

3. Application Characteristics: System core, highly integrated, and value-driven, transforming from an “optional” to a “necessity” influencing performance ceilings.

Q4: Why do electric vehicles need ceramic materials more than gasoline vehicles?

A: Electric vehicles face three fundamental contradictions:

1. High-voltage systems require insulation, but power chips need efficient heat dissipation.

2. motors operate at extremely high speeds, leading to severe wear on traditional bearings.

3. Battery packs require absolutely safe insulation.

Ceramic materials are the only option that can systematically solve these contradictions: aluminum nitride provides both insulation and thermal conductivity; silicon nitride bearings are wear-resistant and insulating; and alumina provides lifelong stable high-voltage isolation. From performance optimization to system enabling, ceramics have become an irreplaceable core material for electric vehicles.

Q5: Do all automotive ceramic parts require expensive precision machining?

A: Not necessarily. Machining requirements depend entirely on the application. Components like spark plug insulators, which don’t have high requirements for absolute dimensions and surface finish, can be “net-shape” through high-precision molds and sintering control, requiring no further machining. This is key to their low cost. However, components like ceramic bearing balls and precision sealing rings, which have extremely high requirements for geometric accuracy and surface quality, must undergo multiple precision grinding and polishing processes. Consequently, their costs are correspondingly higher. Whether to add machining steps is one of the core decisions that ceramic engineers need to make during the design phase when balancing performance, reliability, and cost.

Q6: How does an oxygen sensor work?

A: The oxygen sensor is the engine’s “olfactory organ,” with a zirconia ceramic tube at its core. It utilizes the ionic conductivity of ceramics at high temperatures: when the oxygen concentration inside and outside the ceramic tube is different (air inside, exhaust gas outside), oxygen ions will pass through the ceramic, generating a voltage signal. This voltage value directly reflects the oxygen content in the exhaust gas, thus indicating the air-fuel ratio. The Engine Control Unit (ECU) adjusts the fuel injection quantity in real time based on this signal to ensure efficient and clean combustion. This is a classic example of the functional application of ceramics.

Q7: Why is silicon nitride the preferred choice for high-speed motor bearings?

A: Silicon nitride ceramics are the preferred choice for high-speed motor bearings because they perfectly meet the extreme requirements of electric vehicles:

1. Their density is only 41% that of steel, significantly reducing centrifugal force at high speeds.

2. They have extremely high hardness, with a wear resistance life 3-5 times that of steel bearings.

3. They are completely insulating, completely eliminating the risk of bearing electro-corrosion caused by PWM control.

Their comprehensive performance—lightweight, long lifespan, and high reliability—makes the design of motors exceeding 20,000 rpm possible, and is key to improving power density and reliability.