Introduction

In extremely high-temperature industrial environments, material selection is a test of performance limits. Among them, the melting point of the material defines the theoretical upper limit of its high-temperature resistance and is the first criterion for selecting materials suitable for extreme environments. As rockets pierce the atmosphere and molten metal surges through production lines, what kind of materials can withstand such harsh tests? The answer is advanced ceramics. They have an astonishing melting point far exceeding that of metals, and this property has been transformed into real industrial power. This article will take you on an in-depth exploration, unveiling the complete view of the ceramic melting point from theory to application.

Why Do Ceramics Have a High Melting Point?

The melting point is the temperature at which a substance changes from solid to liquid. Why do ceramics have high melting points? The answer lies in the atomic world.

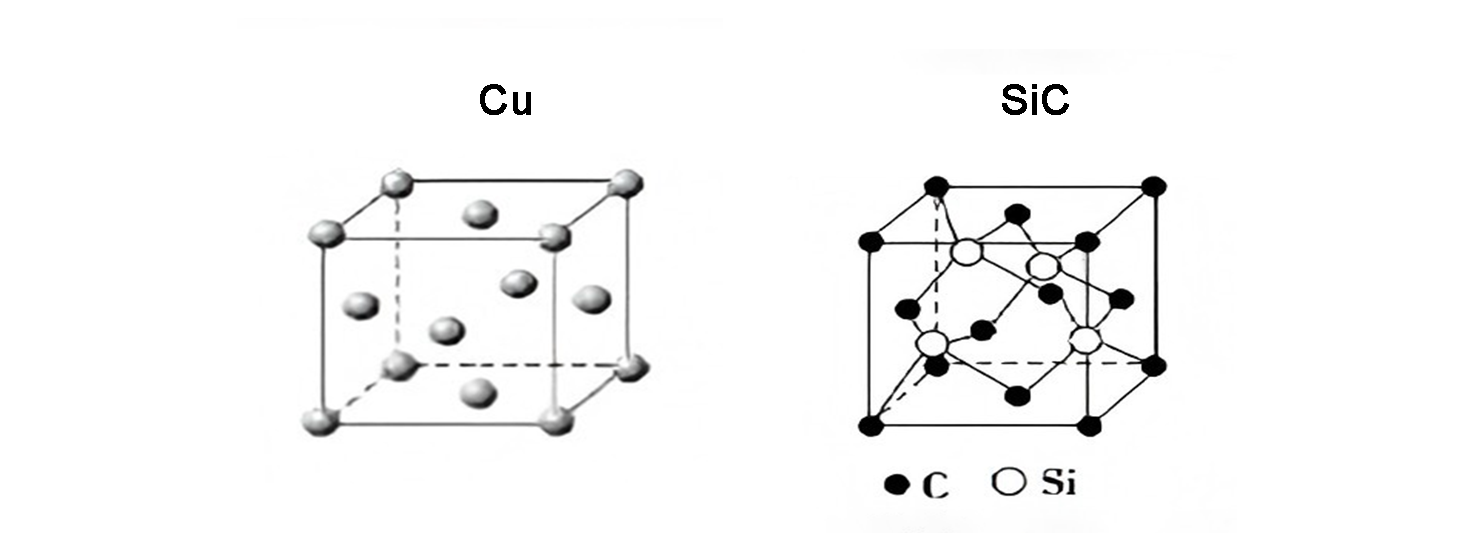

The “freedom” of metals—the metallic bond: Metal atoms have relatively loose bonds between their nuclei and electrons, as if immersed in a sea of free “electron gas”. When heated, atoms readily overcome these bonds and begin to slide, giving metals their characteristic high ductility and relatively predictable melting points (for example, Fe has a melting point of approximately 1538℃).

The “discipline” of ceramics—ionic or covalent bonds: Ceramics consist primarily of metallic and non-metallic elements—such as O, N, and C—bound together by powerful ionic and covalent bonds. This resembles atoms tightly shackled by robust “chains”—they share electrons or are held together by intense electrostatic forces. Breaking these formidable bonds demands enormous energy expenditure, which directly translates into the exceptionally high melting points we observe.

It is this powerful interatomic force that gives ceramics the physical property of “rather break into pieces than remain intact” – they prefer to remain solid at high temperatures until they break, rather than softening and then melting like metals.

Ranking of Melting Points for Mainstream Advanced Ceramics

Theory requires data to support it. The table below clearly shows the melting point of several common advanced ceramic materials, giving us an intuitive understanding of their high-temperature resistance.

| Material Name | Chemical Formula | Theoretical Melting Point (℃) | Maximum Operating Temperature (℃, in atmospheric environment) | Key Features |

| Aluminum Oxide | Al2O3 | ~2050 | 1750 | High hardness, excellent electrical insulation |

| Zirconium Oxide | ZrO2 | ~2700 | 1500 | High strength and toughness, wear-resistant |

| Silicon Nitride | Si3N4 | ~1900 (Sublimation) | 1400 | Excellent thermal shock resistance |

| Silicon Carbide | SiC | ~2730 (Decomposition) | 1650 | Ultra-high hardness, high thermal conductivity |

| Magnesium Oxide | MgO | ~2850 | 2400 | Resistant to alkali corrosion |

Note: The theoretical melting point is the critical temperature at which a material transitions from solid to liquid, while the maximum operating temperature is the practical upper limit at which the material can maintain stable structure and performance over long-term use.

As can be seen from the table, the melting point of advanced ceramics is far higher than that of most metal materials on the market (such as Fe 1538℃), which makes them irreplaceable in high-temperature fields.

The Value of a High Melting Point

What does a high melting point mean? — Irreplaceable applications.

1. Sability at High Temperatures

In the aerospace industry, engine blades and combustion chamber liners must withstand sustained, extreme temperatures. Ceramic-based composites (CMCs) are a crucial component in this environment. Their inherent high melting point allows them to maintain their shape and strength in these harsh environments, contributing to the engine’s stable thrust and exceptional efficiency.

2. Superior Corrosion Resistance

In the chemical and metallurgical industries, pumps, valves, and seals made of advanced ceramics face direct exposure to molten metals and highly corrosive chemical media. Their high melting point allows them to actively resist chemical erosion and reactions from high-temperature media.

3. Stable Electrical Insulation and Thermal Management Capabilities

In the semiconductor industry, advanced ceramic “paddles” and furnace tubes carry silicon wafers through repeated high-temperature processes. These ceramic components, with their exceptional dimensional stability and electrical insulation properties, actively shield chips from contamination during repeated thermal cycles, steadfastly safeguarding chip yield rates.

How Are Advanced Ceramics Made with Such High Melting Points?

Given that advanced ceramics have such high melting points that traditional casting methods cannot process them, how do we transform them into precision components with complex shapes? The answer lies in powder metallurgy—a technique that can be described as the “alchemy” of materials science.

1. Raw Material Preparation: We first grind high-purity raw materials into extremely fine and uniform ceramic powder, laying a solid foundation for subsequent forming.

2. Forming: Subsequently, through advanced processes such as dry pressing, isostatic pressing, or injection molding, these ceramic powders shape within molds, densely consolidating into preset precision forms (referred to at this stage as “green bodies”).

3. Sintering: This is the most critical step. We place the green body in a strictly controlled, high-temperature sintering furnace. In an environment below its melting point, the material actively diffuses atoms in the solid state, eliminating the interfaces between particles, driving the green body to shrink and densify, and eventually transforming into a dense ceramic body with uniform microstructure and excellent performance.

Simply put, it is through the compaction of fine powders and then solid-state sintering at high temperature, so that the atoms between particles diffuse and bond, and finally form dense and complex parts. This cleverly bypasses the melting step.

Conclusion

A deep understanding of the ceramic melting point is fundamental to unlocking the full potential of advanced ceramics. As a specialized supplier of advanced ceramics, we are committed to transforming the frontiers of materials science into reliable solutions for our customers, and to help them overcome every challenge in extreme operating conditions.

FAQs

Q1: Do daily-use ceramics (such as bowls and plates) also have high melting points? What distinguishes them from advanced ceramics?

A: This is a good question that helps us distinguish the fundamental differences between the two types of ceramics. Daily-use ceramics have melting points ranging from approx. 1250°C to 1400°C. While this temperature far exceeds daily environmental conditions, these items are not designed for extreme industrial settings. Their heat resistance largely depends on the surface glaze, and excessive dry heating can cause glaze damage. Advanced ceramics (such as alumina and zirconia) are born to challenge the limits. Their melting points generally exceed 1800°C, and many even exceed 2000°C.

The core difference between the two lies in their composition and performance goals:

1. Composition: Daily-use ceramics are primarily derived from natural clays and silicates. Advanced ceramics, on the other hand, are composed of high-purity synthetic oxides, nitrides, or carbides with extremely strong interatomic bonds.

2. Performance: Daily-use ceramics are designed for aesthetics and practicality. While the core value of advanced ceramics lies in their superior engineering properties, such as high hardness, and high-temperature, wear and corrosion resistance.

In short, when dealing with molten metals, rocket exhaust plumes, or ultra-high-temperature processes in semiconductor manufacturing, advanced ceramics are the only reliable choice.

Q2: Daily-use ceramics have a high melting point, but why do they sometimes crack when placed in an oven?

A: Daily-use ceramics crack not because they’ve reached their melting point, but because they can’t withstand drastic temperature fluctuations (thermal stress). When a section of ceramic heats up or cools down too rapidly, uneven contraction or expansion occurs. This generates internal stresses exceeding the material’s strength, leading to fracture.

There are three main reasons:

1. Microscopic inhomogeneity: Internal defects such as pores and microcracks can easily become cracking sources under thermal stress.

2. Glaze mismatch: The surface glaze and the internal body are two different materials with different thermal expansion coefficients. The opposing forces generated during heating and cooling can cause the glaze to crack or even peel off entirely.

3. Thermal shock: Extreme operations, such as moving directly from a refrigerator to a high-temperature oven, can instantly generate enormous thermal stresses that far exceed the ceramic’s tolerance range.

Therefore, thermal shock resistance (the ability to withstand rapid temperature changes) and melting point are two entirely different concepts. And this is precisely where the weakness of daily- use ceramics lies. In contrast, one of the core properties of advanced ceramics (such as silicon nitride) is their excellent thermal shock resistance.

Q3: Does a higher melting point of ceramics mean better performance?

A: Not necessarily. A high melting point is an important fundamental characteristic, but it’s not the sole criterion for performance. When selecting a material, we need to consider the following:

1. The application scenario determines performance requirements: In applications requiring rapid thermal expansion and contraction, thermal shock resistance (such as silicon nitride) is more important than simply the melting point. In electronic devices that require heat dissipation, thermal conductivity (such as aluminum nitride) is the key performance indicator.

2. Weighing other properties: Materials with extremely high melting points often come with challenges in processing and high costs. Therefore, the optimal solution is to select the material that best suits the specific application and cost budget.

Q4: Why is the actual operating temperature of ceramics significantly lower than its theoretical melting point?

A: This is a crucial distinction. The theoretical melting point refers to the theoretical limit temperature at which a material begins to melt.

In practical applications, however, we focus on the material’s high-temperature performance. As the temperature rises, even before reaching the melting point, ceramics can lose strength, creep (slow deformation), or undergo unwanted chemical reactions with their surroundings (such as oxidation). Therefore, we set the “long-term operating temperature” within a safe range that ensures dimensional stability and reliable performance. This range is typically well below the theoretical melting point.

Q5: In ultra-high temperature environments, which material has greater advantages—ceramics or metals?

A: Advanced ceramics generally offer advantages in extreme high-temperature applications (generally above 1200℃) for the following reasons:

1. Higher temperature resistance: The melting points of most engineering metals and alloys are below 1500℃, while advanced ceramics generally exceed 1900℃.

2. Better high-temperature strength and creep resistance: Ceramics better retain their shape and strength at high temperatures and are less likely to soften or deform.

3. Excellent oxidation and corrosion resistance: Ceramics are generally very stable compounds, resistant to attack by molten metals and many corrosive gases.

Metals, however, offer superior advantages in terms of toughness, electrical conductivity, and machinability. Therefore, we often combine these two complementary materials—ceramics and metals—for use.

Q6: How do I select the right high-temperature resistant ceramic material for my application?

A: Making the optimal choice requires considering multiple factors:

1. Operating Temperature: What are the max. and min. temperatures in your application environment?

2. Thermal Shock: Is the temperature stable, or are there rapid hot-cold cycles?

3. Mechanical Load: How much pressure, wear, or impact must the material withstand?

4. Chemical Environment: Will it be exposed to molten metals, strong acids, strong alkalis, or specific gases?

5. Electrical Performance Requirements: Does it require insulation, thermal conductivity, or specific dielectric properties?

We welcome you to discuss your specific needs and challenges with our technical team. We will provide you with professional selection recommendations based on our extensive experience.