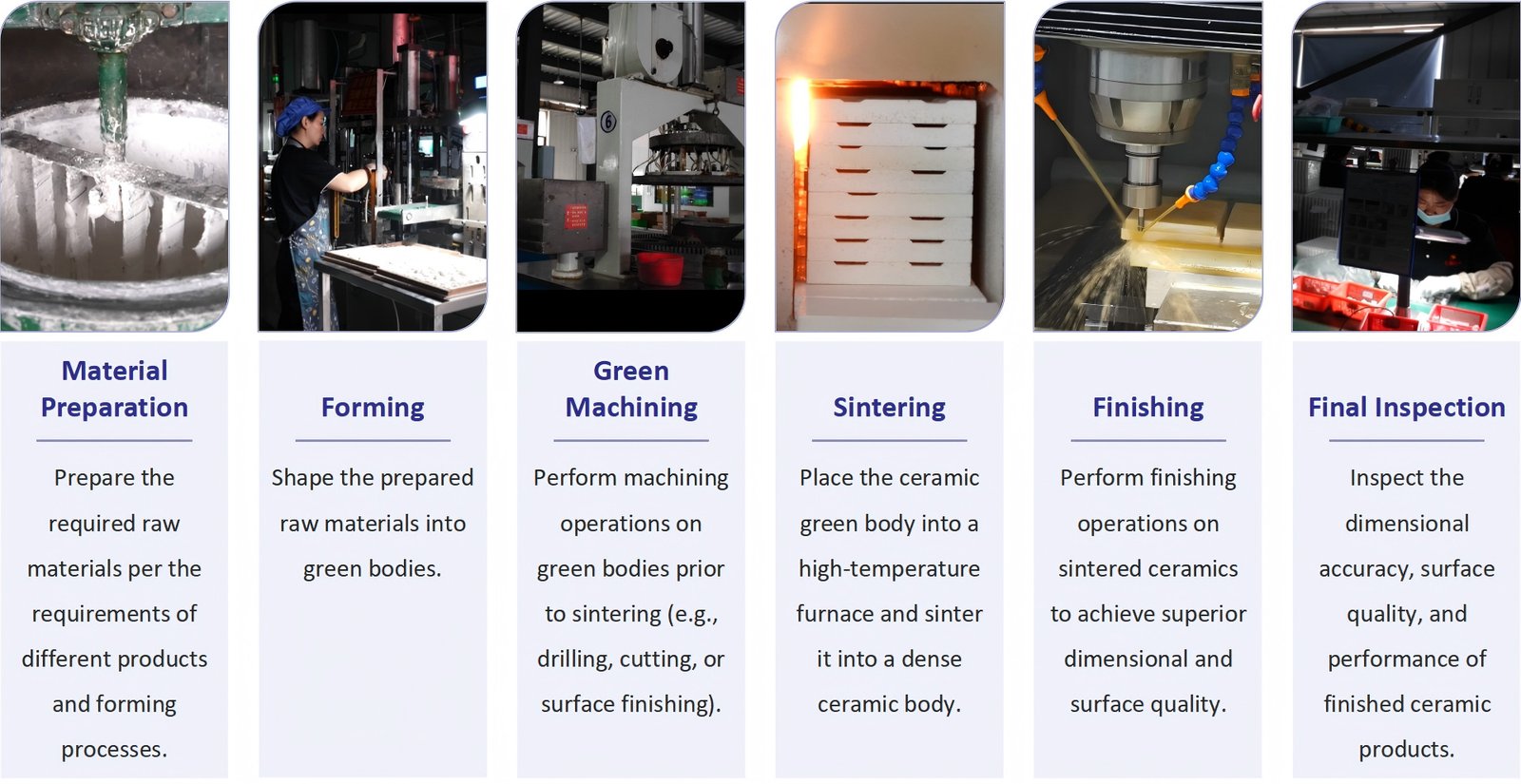

Advanced ceramics manufacturing is a complex process. It involves multiple processes, with the main steps being material preparation, forming, green machining, sintering, finishing, and final inspection. This article will take you into the general process of advanced ceramics manufacturing.

Material Preparation

The material preparation process involves processing high-purity powders through steps such as batching, grinding, and granulation to produce materials (e.g., slurries, granulated powders) that meet the requirements of specific forming processes.

Forming

Forming is the process of placing prepared raw materials into a mold and shaping them into a green body by using a specific forming process. The forming method of advanced ceramics has an important impact on the performance of the product. We comprehensively consider the shape, size, precision, surface quality, output and economic benefits of the product, select the appropriate forming method, and process the ceramic material into the shape we need. Jinghui’s commonly used forming methods include the following.

|

Product Type |

Forming Process |

|||||

|

Dry Pressing |

Hot Pressing | Cold Isostatic Pressing (CIP) | Tape Casting | Extrusion |

Ceramic Injection Molding (CIM) |

|

| ✓ | ✓ | ✓ |

✓ |

|||

| ✓ |

|

|||||

| ✓ | ✓ | ✓ |

|

|||

| ✓ |

|

|||||

| ✓ | ✓ | ✓ |

✓ |

|||

| ✓ |

|

|||||

| ✓ |

|

|||||

| ✓ | ✓ | ✓ |

✓ |

|||

Green Machining

Before sintering, green bodies can undergo machining operations (such as drilling, cutting, or surface finishing) if required. Green machining significantly reduces costs because the green material is relatively soft, requiring less energy and tool wear, and is more efficient. Machining sintered ceramics, on the other hand, requires expensive diamond tools, is more time-consuming, and can increase costs several times over. Therefore, completing as many machining features as possible during the green stage is a highly cost-effective option.

Sintering

Sintering is the process of placing ceramic green bodies into a sintering furnace, where high-temperature treatment causes particles to fuse together, forming a dense structure. The green body undergoes a carefully controlled heating, holding, and cooling process in precision high-temperature furnaces reaching temperatures of up to 1600-1800℃. Ceramic manufacturers rely on precise sintering control to ensure consistent and reliable product performance:

- Adopt fully automatic controlled sintering furnace to ensure the temperature uniformity in the furnace is controlled within a few degrees Celsius.

- Establish an optimal sintering curve database for each material, accurately control the heating rate and holding time to avoid over-sintering or under-sintering.

- Select the appropriate atmosphere (air, nitrogen, hydrogen, etc.) based on product requirements to ensure the stability of the material’s chemical composition. This rigorous process control guarantees that each batch of products exhibits highly consistent microstructure and performance characteristics.

Finishing

If necessary, sintered ceramics can undergo finishing to achieve improved dimensional and surface quality. Common finishing methods include precision grinding, lapping, polishing, and laser processing. After processing, ceramic components can achieve precise dimensional tolerances and ultra-smooth surfaces. This process has the highest technical requirements and is also the most expensive.

Final Inspection

Final inspection includes checking the dimensional accuracy, surface quality, and performance of finished ceramic products. Inspection methods include visual inspection, dimensional measurement, density testing, non-destructive testing (e.g., X-ray inspection), and performance testing (e.g., hardness and strength testing). Only products that pass quality inspection are delivered to ensure their reliability and safety.

Conclusion

From the main production steps above, we can see that advanced ceramic manufacturing is a meticulous process. Each step requires superb skills and strict control. Jinghui is a professional manufacturer of advanced ceramics. Get in touch with us.

FAQs

Q1: Why can “green machining” save money? What are its limitations?

A: Green machining saves money because it processes the ceramic green body before sintering. It has high processing efficiency and low tool wear. However, green machining is only suitable for shaping basic shapes and cannot achieve ultra-high precision and roughness. It still needs to be combined with finishing after sintering.

Q2: Is finishing necessary?

A: Finishing is not necessary. Whether finishing is required depends primarily on the product’s precision and performance requirements. Given that finishing costs are not cheap, it is best to avoid it if possible.

Q3: Can you meet my required dimensional tolerances?

A: We conduct a production feasibility assessment before accepting an order, and we will only accept the order if it is confirmed that it can be done. We typically control dimensional tolerances through appropriate forming technology, strict sintering control, post-sintering finishing, and comprehensive quality monitoring.

Q4: How do I check the quality of ceramic parts after receiving them?

A: You can focus on checking the following: dimensions (using micrometers, coordinate measuring machines, etc.), appearance (no cracks, pores, etc.), and material (you can request the material report and test data that come with the goods).

Q5: What should be noted when using advanced ceramic components?

A: The most common cause of failure in advanced ceramic components during use is localized stress cracking due to improper installation. During installation, you should ensure even force distribution (e.g., using flexible gaskets and tightening gradually in a diagonal sequence) and avoid thermal shock.

Q6: What factors have the greatest impact on the cost of advanced ceramics?

A: There are three key factors that affect the cost of advanced ceramics: raw materials, process complexity, and order quantity.

1. Raw Materials

The cost varies depending on the raw materials used. For example, a simple ceramic structural component might cost USD 15 to make using alumina, but if made using zirconia, the cost could be USD 30~60 or even higher.

2. Process Complexity

The simpler the shape of a ceramic component, the easier it is to form directly, thus reducing the need for finishing after sintering. Furthermore, the looser the dimensional tolerances, the lower the cost.

3. Order Quantity

Mass production can reduce unit costs.

Q7: What is the lead time for advanced ceramics?

A: The lead time for advanced ceramics depends primarily on the complexity of the product and whether it is the first production run. In general:

1. Standard products: If raw materials are in stock, delivery time can be controlled within 4-5 weeks.

2. Customized products require steps such as design review, mold development, and prototyping. The first production cycle is generally 5-8 weeks.