Bulletproof ceramic materials have revolutionized traditional armor protection systems through high-hardness fragmentation mechanisms and lightweight composite structures. This article systematically analyzes the performance characteristics of three core bulletproof ceramics—alumina (Al₂O₃), silicon carbide (SiC), and boron carbide (B₄C)—revealing their three-step bulletproof mechanism of projectile blunting, erosion, and energy absorption . Combining multilayer composite armor design and advances in transparent ceramic technology , it discusses the current applications of ceramic materials in personal protection, military vehicles, and transparent armor, and envisions future development directions such as functionally graded ceramics and self-healing armor.

1 Basic Bulletproof Mechanism of Ceramic Materials

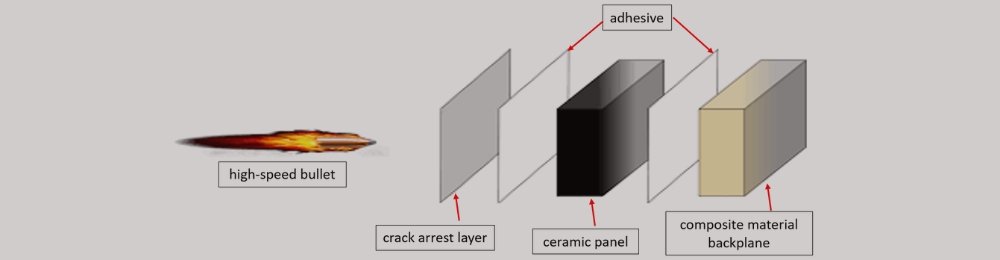

Unlike traditional metal armor that absorbs energy through plastic deformation, ceramics rely on a fragmentation mechanism to achieve bulletproofing . The process involves three stages:

-

Initial Impact Stage:

The projectile impacts the ceramic surface, and due to the extreme hardness of the ceramic (Al₂O₃ HV≥1220-1250, B₄C HV≈2800), it is blunted or shattered, forming a fragmented zone on the ceramic surface . -

Erosion Stage:

The blunted projectile continues to penetrate, forming a continuous layer of ceramic fragments, further consuming kinetic energy . -

Fracture and Absorption Stage:

Tensile stress generated within the ceramic causes fragmentation, and the remaining kinetic energy is absorbed by the deformation of the backing plate material (e.g., UHMWPE fiber, Kevlar) .

The Ballistic Quality Factor (E) is a key indicator for measuring the bulletproof performance of ceramics: E = √(H × E) / ρ, where H is hardness, E is elastic modulus, and ρ is density . Thus, high hardness, high modulus, and low density are the core characteristics of excellent bulletproof ceramics.

2 Main Types of Bulletproof Ceramics and Performance Comparison

2.1 Alumina Ceramics – Al₂O₃

-

Low cost, it is the earliest applied bulletproof ceramic with a density of approximately 3.8 g/cm³ .

-

High hardness (HV 1200-1500), but low fracture toughness, weak resistance to multiple hits .

Widely used in personal bulletproof inserts and Russian armored vehicles (e.g., the latest alumina ceramic armor plates, performance comparable to steel armor but lighter)

2.2 Silicon Carbide Ceramics – SiC

-

-

Excellent comprehensive performance, density approximately 3.07–3.13 g/cm³, hardness HV 2800, elastic modulus 400 GPa .

-

Fracture toughness higher than alumina, resistance to multiple hits significantly improved, used in tanks (e.g., M1, Leopard-II) and helicopter (e.g., Black Hawk) armor .

-

Prepared by reaction sintering or hot pressing sintering, cost higher than alumina, but cost-effective

2.3 Boron Carbide Ceramics – B₄C

-

-

-

Best performance, density only 2.5 g/cm³, hardness HV 2800-3000 (close to diamond), it is the lightest bulletproof ceramic .

-

Expensive (about 10 times the price of alumina), mainly used in high-end bulletproof vests and helicopter pilot seats (e.g., the boron carbide ceramic armor plate of the Z-10 attack helicopter) .

-

-

Hot-pressed sintered boron carbide has good single-hit resistance, while reaction sintered multiphase toughened boron carbide shows potential for defending against multiple hits .

*Table 1: Performance Comparison of Main Bulletproof Ceramics*

| Material | Density (g/cm³) | Hardness (HV) | Elastic Modulus (GPa) | Fracture Toughness (MPa·m¹/²) | Cost |

|---|---|---|---|---|---|

| Al₂O₃ | 3.8 | 1200-1500 | 340 | 2.8-4.0 | Low |

| SiC | 3.07-3.13 | 2800 | 400 | 3.9-4.3 | Medium |

| B₄C | 2.5 | 2800-3000 | 400-440 | 2.9-3.1 | High |

3 Core Application Fields of Bulletproof Ceramics

3.1 Personal Protective Equipment

-

Ceramic Composite Bulletproof Inserts: Composed of a ceramic front plate (Al₂O₃/SiC/B₄C) and a fiber backing plate (PE/Kevlar), can be inserted into tactical vests .

-

Lightweight Advantage: Silicon carbide inserts are 400g lighter than equivalent alumina inserts (against 5.56mm SS109 bullet), or have a higher protection level at the same weight (can protect against 7.62mm armor-piercing incendiary bullets) .

3.2 Military Vehicle Armor

-

Land Platforms: Used in tank composite armor (e.g., M1 main battle tank), infantry fighting vehicles (e.g., Stryker armored vehicle uses cermet composite materials), and personnel carriers .

-

Aviation Applications: Helicopters like Apache, Black Hawk, and Z-10 widely use ceramic armor to protect pilots and critical systems against 12.7mm heavy machine gun fire and missile fragments .

3.3 Transparent Ceramic Armor

-

To meet observation requirements, transparent ceramics such as sapphire (single crystal α-Al₂O₃), magnesium aluminate spinel (MgAl₂O₄), and aluminum oxynitride (AlON) are used in bulletproof visors, vehicle observation windows, and sensor protection windows .

-

Transparent armor is typically a multilayer composite structure: the strike face is high-hardness transparent ceramic, the intermediate layer is high-toughness polymer or glass, and the backing layer is a ductile transparent material .

Sapphire has the best static parameters, but fine-grained polycrystalline ceramics (e.g., magnesium aluminate spinel) often have better actual bulletproof效果 due to their specific fragmentation mode .