Introduction: Why is Aluminium Nitride Ceramics Becoming the New Favorite in the Electronics Industry?

In today’s rapidly developing electronics industry, thermal management has become a bottleneck restricting technological progress. As chip power density continues to increase, traditional alumina ceramic substrates can no longer meet the requirements for efficient heat dissipation. At this point, aluminium nitride ceramics (AlN) emerged as the next-generation star product for electronic packaging and substrate materials. So what makes aluminium nitride ceramics so attractive that it becomes the ideal choice for high-power electronic devices? This article will explore the characteristics, applications, manufacturing processes, and future development trends of aluminium nitride ceramics in depth.

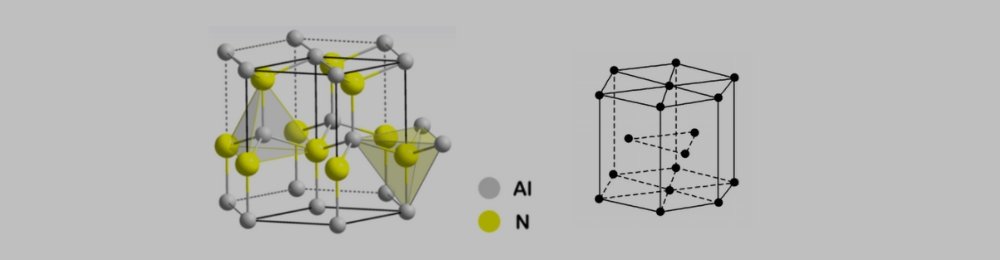

What is Aluminium Nitride Ceramics?

Aluminium nitride (AlN) is a hexagonal covalent compound formed by nitrogen and aluminum elements, appearing white or gray-white in color. It not only has excellent thermal conductivity but also possesses a thermal expansion coefficient that matches silicon, making it an ideal material in the field of semiconductor packaging.

Aluminium nitride ceramics are advanced ceramic materials made primarily from aluminium nitride powder through forming and high-temperature sintering. Its theoretical thermal conductivity is as high as 280-320 W/(m·K), 7-10 times that of alumina ceramics, which directly establishes its core position in the thermal management field for high-power electronic devices.

Outstanding Characteristics of Aluminium Nitride Ceramics

1. Excellent Thermal Properties

The most notable feature of aluminium nitride ceramics is its ultra-high thermal conductivity. In practical applications, the thermal conductivity of aluminium nitride ceramic substrates can reach 180-230 W/(m·K), far exceeding traditional alumina ceramics (about 20 W/(m·K)). This means it can more quickly conduct heat away from chips, preventing device failure due to overheating.

Furthermore, the thermal expansion coefficient of aluminium nitride ceramics (4.6×10⁻⁶/K, 40-400°C) is very close to that of silicon (4.1×10⁻⁶/K). This matching ensures that between the aluminium nitride substrate and the silicon chip, excessive stress won’t be generated due to differences in thermal expansion during temperature changes, thereby improving product reliability and lifespan.

2. Excellent Electrical Insulation Properties

Aluminium nitride ceramics have high resistivity (>10¹⁴ Ω·cm) and high breakdown strength (>15 kV/mm), making them ideal electrical insulation materials. At the same time, its dielectric constant is relatively low (about 8.5), which helps reduce signal transmission delay and crosstalk, demonstrating excellent performance in high-frequency circuit applications.

3. Good Mechanical Properties

Aluminium nitride ceramics have a flexural strength of up to 350-450 MPa and a Vickers hardness of about 11 GPa, with mechanical strength surpassing traditional alumina ceramics. This enables it to perform well in application scenarios requiring high mechanical strength.

4. Other Characteristics

Aluminium nitride ceramics also offer advantages such as high temperature resistance, chemical corrosion resistance, strong corrosion resistance to molten metals, and non-toxic environmental protection. These comprehensive properties make aluminium nitride an all-rounder in electronic packaging materials.

Key Application Areas of Aluminium Nitride Ceramics

1. Heat Dissipation Substrates for High-Power Electronic Devices

With the development of 5G communication, new energy vehicles, and industrial control, high-power IGBT modules, microwave power amplifiers, and other devices are placing increasingly higher demands on heat dissipation. Aluminium nitride ceramic substrates can effectively conduct and dissipate the large amount of heat generated by these devices, ensuring stable equipment operation.

2. LED Packaging

The heat generated by high-brightness LEDs directly affects their light efficiency and lifespan. Using aluminium nitride ceramic substrates in LED packaging not only provides excellent thermal dissipation performance but also offers good light reflectivity (light reflectivity of some models can reach 35%), helping to improve the overall light efficiency of LEDs.

3. Semiconductor Packaging and Integrated Circuits

Aluminium nitride ceramics are ideal packaging materials for multi-chip modules (MCM) and large-scale integrated circuits. Its high thermal conductivity can effectively solve heat dissipation problems caused by high-density integration, while its thermal expansion coefficient matching that of silicon ensures the reliability of the packaging structure.

4. High-Temperature and High-Frequency Applications

The stable performance of aluminium nitride ceramics gives it unique advantages in high-temperature environments (such as automotive electronics, oil exploration) and high-frequency fields (such as microwave communication, radar systems).

5. Other Applications

Additionally, aluminium nitride ceramics are also used to make laser diode carriers, corrosion-resistant components for high-temperature turbines, infrared windows, GaAs crystal crucibles, and more.

Manufacturing Process of Aluminium Nitride Ceramics

Powder Preparation

High-quality aluminium nitride powder is the foundation for preparing high-performance aluminium nitride ceramics. Industrially, the carbothermal reduction method is mainly used to prepare aluminium nitride powder: aluminum oxide powder is mixed with carbon powder and reacted at high temperature in a nitrogen atmosphere to generate aluminium nitride powder.

High-quality aluminium nitride powder has characteristics such as high purity (>99.9%), small particle size (1-3μm), narrow particle size distribution, and spherical particle morphology. These characteristics are crucial for the subsequent forming and sintering processes.

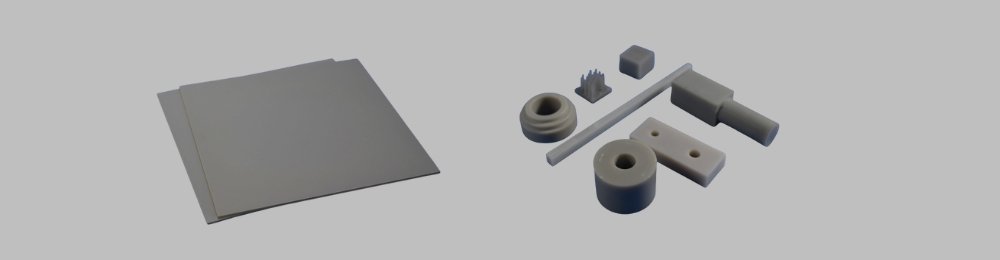

Forming Process

Aluminium nitride ceramic substrates are mainly prepared using the tape casting process. Traditional tape casting uses toxic organic solvents, which are harmful to the environment and human health. In recent years, new processes such as gel tape casting are being developed, which combine the advantages of gel casting and tape casting technologies, can use non-toxic solvents, reduce environmental pollution, and simultaneously lower sintering temperatures.

The green body obtained after tape casting needs to go through binder removal (removing organic additives) and high-temperature sintering processes to obtain dense aluminium nitride ceramic substrates.

Sintering Process

The sintering temperature of aluminium nitride ceramics is as high as 1800-1900℃, with relatively high energy consumption. To promote sintering and improve thermal conductivity, it is usually necessary to add sintering aids, such as rare earth or alkaline earth metal oxides like Y₂O₃, CaO, etc.

Research shows that composite addition of multiple sintering aids can meet both high thermal conductivity and low-temperature sintering requirements. By optimizing sintering aids and sintering processes, the thermal conductivity of aluminium nitride ceramics can reach up to 248 W/(m·K), close to the theoretical value.

Surface Metallization Technology for Aluminium Nitride Ceramics

To create circuits on aluminium nitride ceramic substrates, surface metallization treatment is required first, that is, forming a metal layer firmly bonded to the ceramic surface. Commonly used metallization methods include:

1. Thick Film Metallization

Thick film metallization is a technology that applies metal paste to an aluminium nitride substrate through screen printing, and then forms metal circuits through sintering. Metal paste typically consists of a conductive phase (such as silver, gold, copper, etc.), a bonding phase (glass frit or reactive binder), and an organic vehicle.

Research shows that when using CaO-B₂O₃-SiO₂-BaO system glass as a binder, with a glass content of 10%, the adhesion between the Ag conductor layer and the AlN substrate can reach 11.74 MPa.

2. Thin Film Metallization

Thin film metallization uses physical vapor deposition methods such as sputtering and evaporation to form micron-thick metal layers on aluminium nitride substrates. This method can obtain higher precision circuit patterns, but the equipment cost is higher.

3. Direct Bonded Copper (DBC)

DBC technology directly bonds copper foil onto an aluminium nitride substrate to form circuit patterns. This structure has excellent thermal and electrical conductivity and is suitable for high-power devices.

Selection Guide for Aluminium Nitride Ceramic Substrates

Facing different specifications of aluminium nitride ceramic substrates on the market, how to choose the right model? Here are some key considerations:

| Selection Parameter | Considerations | Typical Values |

|---|---|---|

| Thermal Conductivity | Select according to device power density and heat dissipation requirements | 170-230 W/(m·K) |

| Flexural Strength | Consider mechanical strength requirements and installation conditions | 350-450 MPa |

| Dielectric Constant | High-frequency applications require lower dielectric constant | About 8.5 |

| Dimensional Stability | Pay attention to warpage and machining tolerance | <0.002/mm |

| Metallization Type | Select according to process compatibility and cost | Thick film, thin film, DBC |

| Operating Temperature | Ensure material suitability for application environment temperature | -55℃ to 850℃ |

Future Development Trends of Aluminium Nitride Ceramics

1. Cost Reduction

Currently, the production cost of aluminium nitride ceramics remains high, mainly due to expensive high-quality powder and high sintering energy consumption. In the future, by optimizing powder preparation processes, developing new sintering aids, and reducing sintering temperatures, it is expected to significantly reduce the production cost of aluminium nitride ceramics.

2. Environmentally Friendly Manufacturing

Traditional tape casting processes use toxic solvents that are environmentally unfriendly. New processes such as water-based tape casting and gel tape casting are under development, using non-toxic or less toxic solvents to reduce harm to the environment and human health.

3. Integration and Multilayering

As electronic equipment develops toward miniaturization and lightweight, the demand for multilayer aluminium nitride ceramic substrates is growing. By alternately stacking multiple circuit layers with dielectric layers and creating interconnection pathways between layers, higher-density three-dimensional integration can be achieved.

4. Expansion into New Application Fields

Aluminium nitride ceramics are gradually expanding into new fields such as biomedicine, aerospace, and defense military industry. For example, using the biocompatibility of aluminium nitride, medical implants can be made; using its high-frequency performance, microwave components can be produced.

Conclusion

With its excellent thermal conductivity, thermal expansion coefficient matching silicon, and superior electrical insulation, aluminium nitride ceramics have become an ideal material for high-power, high-density electronic packaging. As preparation technology advances and costs decrease, aluminium nitride ceramics are expected to replace traditional alumina ceramics in more fields, providing key technical support for the miniaturization and high-power development of electronic equipment.

For electronic engineers and product designers, deeply understanding the characteristics of aluminium nitride ceramics and applying them appropriately will help develop more efficient and reliable electronic equipment to meet the challenges of future technological development.