Hot pressing sintering is a simultaneous heating and pressing sintering process used for difficult-to-sinter powder materials. It involves loading raw material powder into a metal or high-strength graphite mold cavity, applying pressure while heating to the normal sintering temperature or slightly lower, and sintering the powder into a dense, uniform, and fine-grained ceramic material in a short time. This method is particularly critical for manufacturing high-performance advanced ceramics, where density and microstructure determine final properties.

Characteristics of Hot Pressing Sintering Process

1 Unique Advantages

-

Enhanced Densification: The additional pressure provides a driving force for material migration, enabling densification at lower temperatures and in shorter times compared to conventional sintering. For instance, AlN ceramics prepared by hot pressing achieve a thermal conductivity of 200 W/m·K, significantly higher than those made by conventional sintering.

-

Fine-Grained Microstructure: The process inhibits grain growth, resulting in fine grains that improve mechanical properties. For example, fine-grained alumina ceramics with a grain size of 0.5μm and a flexural strength of 500MPa can be obtained by hot pressing at 1450°C.

-

High Purity Products: It often requires no or minimal sintering aids, allowing the production of ultra-high purity ceramic products.

2 Limitations

-

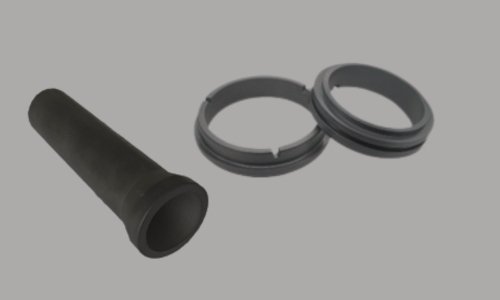

Shape Simplicity : It is generally suitable for manufacturing products with relatively simple shapes.

-

High Cost and Low Efficiency: The equipment is complex, and the process has high requirements, leading to high processing costs and low production efficiency.

Comparison with Other Ceramic Processes

Process Principle Advantages Limitations Typical Applications Hot Pressing Sintering Simultaneous heating and pressing High density, fine grains, high performance High cost, simple shapes Structural ceramics like AlN, Si3N4 Hot Die Casting Sintering at atmospheric pressure Simple, cost-effective, complex shapes Binder removal required, lower density coarser grains Common ceramic products Hot Isostatic Pressing (HIP) Isostatic pressure with gas at high temperature Uniform density, complex shapes possible High equipment cost / High-value, critical components Key Differentiator :

Hot pressing sintering’s defining feature is the application of uniaxial pressure during sintering, which enhances densification and refines microstructure compared to pressureless conventional sintering. Unlike Hot Isostatic Pressing (HIP), which uses gas pressure for omnidirectional compression, hot pressing typically uses uniaxial pressure. HIP can handle more complex shapes, but hot pressing sintering is often more straightforward for simpler geometries.Hot Pressing Sintering Equipment and Process Flow

1 Equipment Components

A hot pressing sintering furnace is primarily composed of:

-

Heating System : Often uses graphite heating elements capable of reaching temperatures up to 2500°C.

-

Pressure System : A mechanical or hydraulic device applying uniaxial pressure.

-

Mold : Typically made of high-strength graphite, with maximum sizes known to reach up to Φ80cm, capable of withstanding 2200°C and 80MPa pressure. To prevent reactions, the mold inner wall is often coated with BN powder.

-

Atmosphere Control : Can operate under vacuum or protective atmospheres (e.g., N2, Ar).

2 Process Flow

-

Powder Preparation : Raw powder is dried, and its moisture content is strictly controlled (e.g., below 0.2%).

-

Mold Filling : Powder is loaded into the pre-treated mold.

-

Heating & Pressing : Under a protective atmosphere, temperature and pressure are applied simultaneously according to the set process curve.

-

Heat Preservation : Maintain temperature and pressure for a certain duration to achieve complete densification.

-

Cooling & Demolding : Cool to room temperature and remove the sintered compact.

Applications of Hot Pressing Sintering in Advanced Ceramics

1 Silicon Nitride (Si3N4) Ceramics

Hot pressing sintering is a primary method for producing dense silicon nitride ceramic materials. Researchers have used hot pressing sintering with different rare earth oxide sintering aids to prepare silicon nitride sintered bodies with thermal conductivity as high as 114.7 W·m⁻¹·K⁻¹ and 129 W·m⁻¹·K⁻¹, the latter accompanied by a bending strength as high as 1149MPa.

2 Aluminum Nitride (AlN) Ceramics

Studies show that the thermal conductivity of AIN ceramics obtained by hot pressing sintering under the same conditions is higher than that by conventional pressure sintering. The lattice oxygen content in hot-pressed sintering AIN ceramics is lower, resulting in a thermal conductivity of 200 W/m·K.

3 Boron Carbide (B4C) Ceramics

Due to its strong covalent bonds, boron carbide is difficult to densify. The hot pressing sintering densification process involves three continuous mechanisms: particle rearrangement, plastic flow, and volume diffusion with pore elimination, occurring in specific temperature ranges (e.g., 1800~2200°C).

4 Alumina (Al2O3) Ceramics

Introducing AlTiC intermediate alloy into alumina ceramics and preparing TiC/Al2O3 composites by transient liquid phase hot pressing sintering can inhibit alumina grain growth. Fine-grained alumina ceramics with a grain size of 0.5μm and flexural strength of 500MPa can be obtained by hot pressing at 1450°C.

Trends of Hot Pressing Sintering Technology

-

Process Combination : Combining hot pressing with other techniques, such as Hot Pressing + Transition Liquid Phase Sintering used in preparing TiC/Al2O3 composites, enhances sintering quality.

-

Equipment Innovation : Development towards larger mold specifications (e.g., up to Φ80cm), higher temperature and pressure capabilities, and improved automation to enhance efficiency and reduce costs.

-

Material Systems Expansion : Application of hot pressing sintering in new material systems such as ceramic matrix composites (CMCs) and high-entropy ceramics.

Hot pressing sintering technology, with its unique advantages of simultaneous pressure and heat application, plays an indispensable role in the preparation of high-performance advanced ceramics. Despite challenges like cost and shape limitations, as technology advances and innovations emerge—such as novel thermoformable ceramics—hot pressing is expected to see broader applications in fields demanding extreme performance, including aerospace, electronics, and defense.

-

-