Ceramic Guide Manufacturing Expert

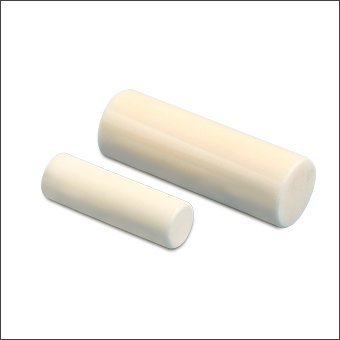

Made of advanced materials such as alumina (Al₂O₃) and zirconia (ZrO₂), ceramic guides have excellent wear resistance, corrosion resistance and low friction. They are precision parts designed for textile machinery and have excellent durability and performance in high-speed yarn processing.

The ceramic guides provided by Jinghui can minimize yarn damage and extend service life. They are suitable for upgrading and transformation of smart spinning production lines that pursue low breakage rate and high output. We have a variety of stock sizes for you to choose from, and we can also customize them for you if necessary. Welcome to inquire.

By Features

Ceramic guide is the one of the main product type of texitile ceramics, and main materials of ceramic guides are 95% alumina, 99% alumina, zirconia and titania ceramic. Product types include eyelet, roller, pigtail, traverse guide, bobbin, hook, etc.

Smooth fiber threading in textile machinery, reducing friction and yarn breakage.

Precision alignment for wire ropes and cables in textile production line.

Wear-resistant loops for high-speed yarn winding in spinning machines.

Rollers to prevent temperature accumulation during yarn high-speed movement.

Low-friction linear motion in semiconductor wafer handling systems.

Curved surface for tension control in weaving looms and braiding machines.

The narrow slits are precisely positioned for yarn alignment and diversion during motion.

Uniform yarn distribution in winding machines for textile and packaging.

Technical Specifications

Below are the general specifications/performance characteristics we offer. If you have different requirements, do not hesitate to let us know.

High-purity alumina (95%/99% Al₂O₃), yttria-stabilized zirconia (YSZ) or titania (TiO2).

Alumina ceramic guide: up to 1600°C; zirconia ceramic guide: up to 1000°C.

Compatible with machinery up to 25,000 RPM.

Mirror-polished (Ra ≤0.4μm) to reduce yarn abrasion.

Key Benefits

Jinghui can provide competitive ceramic guides to meet your business growth.

10x longer than steel guides, reducing replacement costs.

Low friction lowers power consumption by 15-20%.

Withstands acidic dyes, humidity, and harsh chemicals.

Tailored geometries (eyelet, roller, multi-channel) for OEM integration.

Scalable solutions with strict ISO quality control.

Ensures ±0.005 mm tolerance if need.

High-quality Service for You

Ceramic Guides by Jinghui are precision-engineered components designed for textile machinery, offering low friction, high wear resistance, and corrosion protection. Made from advanced materials like alumina and zirconia, these guides ensure smooth yarn handling, minimize fiber damage, and extend machinery lifespan. Ideal for spinning, weaving, and dyeing processes, they reduce downtime and energy consumption. With ISO 9001 certification and 15+ years of expertise, Jinghui delivers custom ceramic guides tailored to OEM specifications, trusted by global clients in automotive, aerospace, and industrial sectors.

Ceramic guides offer 10x longer lifespan, 30% lower yarn breakage, and corrosion resistance, outperforming metal guides in harsh environments like dyeing and high-speed spinning.

Yes! Jinghui’s ceramic guides are designed for speeds up to 25,000 RPM, ensuring smooth operation and minimal wear even in demanding conditions.

Absolutely. We can provide excellent products in time to match OEM requirements, ensuring seamless integration into existing systems.