Technical SPECs

| parameter | Standard range | capabilities |

| outer diameter | 1-150 mm | ±0.01 mm |

| wall thickness | 0.5-20 mm | When too thin, reinforce the rib design |

| length | 10-800 mm | too long, needs to be sintered and spliced |

| Surface roughness Ra | 0.1-0.4 μm | mirror polishing,Ra≤0.05 μm |

| Roundness deviation | ≤0.1% | ≤0.05%(Precision grade) |

Zirconia Tube Manufacturing Experts

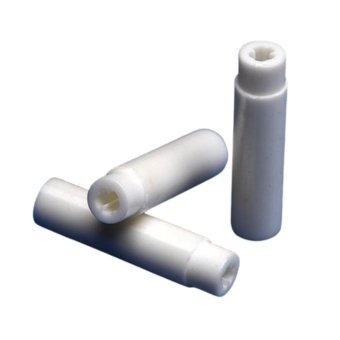

If you are looking for a professional zirconia tube factory in China, Jinghui ceramic is your first choice. We have over 200 styles of zirconia pipe to support your business.

As a special advanced ceramics supplier since 2008, we have 10 expert designers and can supply 2D and 3D drawings based on your project needs or even ideas, you can customize your zirconia tubes, just give your project details, and we will design free for you.

We can supply zirconia tube with various length and diameter. Our ceramic tubes are also available in a variety of color options for meeting industry standards. Trust us to provide reliable, customizable solutions to you.

Product By Features

Zirconia tube is a common product application of zirconia ceramic materials. We are able to customize ceramic tubes to your specifications in a variety of shapes, and these products below are just a few of our many offerings.

Side wall holes are used for functional structural needs.

Shape similar to the structural function of I-channel steel.

Frustum-shaped tube, used in corresponding special structural environments.

The inner circle has grooves for corresponding functional structures.

Magnesium stabilized zirconia tube with end face steps for corresponding connections.

The outer circle has a rotating groove for use similar to gear meshing.

Zirconia Tube Advantages & Limitations

Wear life: 5-8 times that of alumina tubes;

High-temperature stability: Strength retention >80% at 1600°C (industry average 60-70%);

Cost: Approximately 2-3 times higher than alumina tubes (but lifecycle costs are 40% lower);

Compound reinforcement: Adding Al₂O₃ or SiC fibers improves impact resistance.

Jinghui ceramic significantly inhibits phase transition through yttrium stabilization and grain boundary doping.

We mainly process zirconia tubes less than 800mm. For longer tubes, we need to consider segmented sintering + laser welding, which may be achieved through our partners.

Zirconia tubes have the following characteristics: ① Lower metal ion precipitation (Na/K < 0.1 ppm); ② Higher plasma resistance (etching rate < 0.1 μm/h); ③ Better thermal stability (deformation < 0.01% at a temperature difference of 500°C). However, the cost is relatively high and it is suitable for high-end processes (below 7nm).

1. Flexible metal transition sleeve (CTE matching design);

2. Prestressed finite element analysis service (simulation of installation stress distribution);

3. Surface compression treatment (using thermal shot peening to form a 200 MPa compressive stress layer) to reduce the installation damage rate to <0.5%.