Characteristics and Benefits

- Ideal surface smoothness, roughness and flatness.

- Excellent fracture toughness: up to 10 MPa·m1/2.

- High hardness: 90 HRA (approx. 10 times than that of steel).

- Exceptional wear resistance with lowest friction coefficient (0.15).

- Superb flexural strength: 2~3 times of alumina substrate (>350 MPa).

- High electrical isolation: ideal for chip packaging and high voltage circuits.

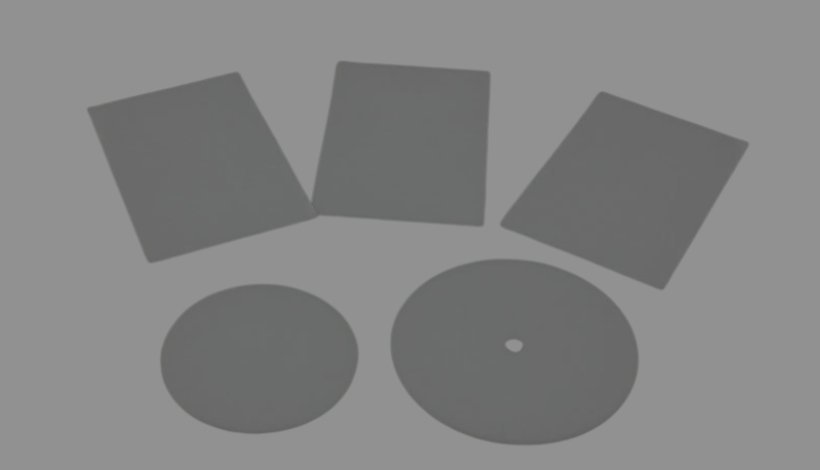

High Performance Zirconia Substrate Manufacturer in China

Our zirconia substrate is made of high-purity zirconia ceramic through tape casting or dry pressing processes. After precision sintering, the density of the zirconia substrate can reach 99.6%. The substrate has the following excellent properties:

※ The MohS hardness can reach 9.

※ The wear resistance is 40% higher than that of traditional ceramics.

※ It offers a very low coefficient of thermal expansion of 3.0×10⁻⁶/℃.

※ Superior reliability under harsh conditions from -50℃ to 800℃.

Therefore, it provides a stable foundation for your chip packaging, sensor manufacturing and high-end devices.

Our entire production process strictly complies with the ISO9001:2015 quality management system. All substrates undergo ultrasonic flaw detection and electrical performance testing before leaving the factory, with a defect rate of less than 0.3%. If you can provide us with valuable cooperation opportunities, we will repay your trust and help your business grow.

By Features

The zirconia substrate has a variety of characteristics. Our typical products are as follows.

-

0.25mm, 0.15mm available. The minimum thickness can be 0.10mm.

-

A kind of circular substrate for cutting-edge technologies.

-

Black because of the formula and preparation technology.

-

To optimize the surface quality and enlarge the uses.

-

Laser Cutting Zirconia Substrate

Laser Cutting Zirconia SubstrateVarious custom patterns can be obtained after laser cutting.

An Overview of Zirconia Substrate

Zirconia (ZrO2) substrates are high-performance ceramic components made of zirconia ceramic as the main raw material, usually doped with yttrium oxide (Y2O3), magnesium oxide (MgO) and calcium oxide (CaO) as stabilizers, through advanced forming and precision sintering processes.

Core Properties Comparison with Other Substrates

| Property | Performance | Compared with Al2O3 and AlN Substrates |

| Mechanical | ▶ Higher fracture toughness (6~10 MPa·m1/2) than alumina substrates.

▶ Bending strength ≥1000 MPa. |

It offers excellent impact resistance, ideal for high-load scenarios. |

| High-temp resistance | ▶ Melting point is as high as 2700℃.

▶ Can work stably for a long time at above 1000℃. |

It is comparable to silicon carbide (SiC), but has poorer thermal conductivity. |

| Chemical stability | It is resistant to strong acids, strong alkalis and erosion by molten metals, and has excellent biocompatibility. | It is superior to aluminium nitride (prone to hydrolysis) and aluminium oxide (with slightly weaker acid resistance). |

| Thermal conductivity | Low (2-3 W/m·K), not suitable for high-power heat dissipation scenarios, but ideal for heat isolation. | Much lower than aluminum nitride (170-200 W/m·K). |

| Ionic conductivity | It is an oxygen ion conductor at high temperature (>600℃) and is used as electrolyte for solid oxide fuel cells (SOFCs). | Other ceramic substrates (such as Al₂O₃) do not have this property. |

Pros and Cons of Zirconia Substrate

| Pros | Cons |

| It has strong fracture resistance, close to that of metal materials, so it is called ceramic steel. | Poor thermal conductivity, not suitable for heat dissipation scenarios. |

| Excellent corrosion resistance, suitable for harsh chemical environments. | Stabilizer is required at high temperature, otherwise it is easy to change phase and crack. |

| Good biocompatibility, suitable for medical implants. | The cost is higher than alumina, and the process is more complicated. |

The Typical Application of Zirconia Substrate

- High-strength applications: Aerospace components, automotive sensors (such as oxygen sensors), and industrial wear-resistant parts.

- Medical applications: Dental restorations and artificial bones.

- Electronic devices: High-temperature circuit substrates and fuel cell electrolytes (SOFCs).

It is not as commonly used as a ceramic substrate material as alumina (Al2O3) and aluminum nitride (AlN). However, it is used as a ceramic substrate material when high toughness, high wear resistance, and chemical stability are required in specific scenarios.

The selection of ceramic substrate materials mainly depends on the following three aspects:

- Application scenarios: electronics, high temperature, and mechanical load.

- Performance: heat dissipation, insulation, and mechanical strength.

- Batch application cost.

Typical ceramic substrate materials in different fields are aluminum oxide (Al2O3), aluminum nitride (AlN), and silicon nitride (Si3N4). While zircona, due to its poor thermal conductivity, is only used as a substrate material in biomedicine and high-temperature sensing.

The core manufacturing process of ceramic substrate includes four steps:

- Material preparation: It is necessary to select the powder grade, additives, adhesives, etc.

- Ceramic body forming: It mainly includes forming processes such as tape casting, dry pressing, and isostatic pressing.

- Precision sintering: It is a key step in ceramic densification, and it requires strict control of the introduction temperature, time, and atmosphere.

- Post-processing: It mainly includes precision cutting, polishing, laser drilling, metallization, etc.

The typical thickness of ceramic substrates varies greatly depending on the material type, application scenario and production process. Please refer to the table below.

| Substrate Material | Typical Value of Thickness |

| Alumina (Al2O3) | 0.3mm ~ 1.5mm |

| Aluminum Nitride (Si3N4) | 0.25mm ~ 1mm |

| Silicon Nitride (Si3N4) | 0.5mm ~ 3.0mm |

| Zirconium Oxide (ZrO2) | 0.1mm ~ 0.5mm |

| Low Temperature Co-fired Ceramics (LTCC) | 0.1mm ~ 0.5mm (single layer) |

The selection and influence of substrate thickness are generally weighed from the following aspects:

- High power VS mechanical strength:

High power devices generally choose thinner aluminum nitride substrates (such as 0.3mm thick). While for high mechanical loads, they prefer slightly thicker silicon nitride substrates (such as 2.0mm thick).

- High frequency VS insulation high voltage

High frequency devices generally choose LTCC substrates (such as 0.20mm thick), while high voltage insulation chooses thicker alumina substrates (such as 1.5mm thick).

- Cost VS performance

If the budget is insufficient and the requirements are not very high, alumina substrates, especially 1.0mm thick substrates, are an ideal choice; if there are high-performance requirements, 0.3mm thick aluminum nitride substrates are better.