Key Advantages

Ceramic insulator for spark plug having the following product highlights , these characteristics are crucial for spark plugs to operate under high temperature, high pressure, and high voltage conditions.:

–Excellent electrical insulation: effectively prevents high-voltage leakage and ensures stable spark energy;

–Excellent thermal conductivity and thermal shock resistance: able to withstand drastic temperature changes inside the engine and avoid cracking;

–High mechanical strength and durability: Utilizing high alumina materials ensures structural integrity and long service life under complex working conditions;

–Precise dimensional stability and chemical resistance: Maintains dimensional stability in the combustion chamber environment and resists corrosion from fuel additives and exhaust gases.

Your Reliable Spark Plug Ceramic Parts Partner

Jinghui Ceramic is a manufacturer of advanced ceramic products with 10+ years of production experience. Our ceramic insulators for spark plug are mainly based on 95% alumina ceramic materials, and production processes is hot pressing , are widely used in various ignition systems and combustion equipment, such as gasoline engines, household gas stoves, gas water heaters, gas ovens, and various industrial gas stoves.

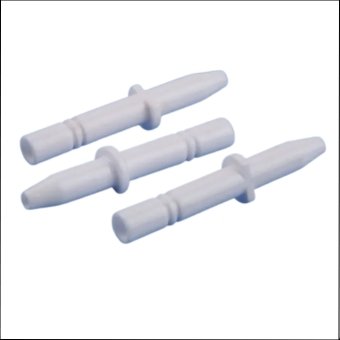

As we all know, spark plug ceramic parts are often customized to meet customer requirements, and the customization requirements vary across industries and applications. To meet these demands, we not only support a variety of special shapes but also optimize ceramic materials based on the product’s specific characteristics.

To date, we have served over 500 customers in industrial applications. We are committed to implementing our technology and creating value through our experience. Therefore, we are not just a supplier, but also a partner. We look forward to welcoming you.

Product By Features

We are engaged in offering a quality range of ceramic igniter parts. They can withstand 20KV high voltage, high current and high temperature of 1600ºC. The following products are some of our representative regularly supplied products.

Quality and Reliability of Spark Plug Ceramic

The ceramic igniter components we produce generally undergo a glazing process to ensure that the glaze is evenly distributed on the surface of the component.

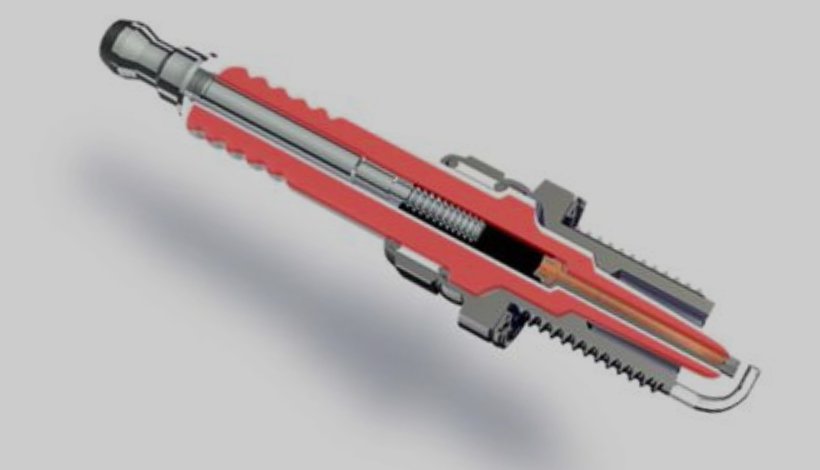

Spark plugs are an important component of the ignition systems , consist of a ceramic tube, pins, and a lead wire. The connection between the pins and the lead wire is fixed inside the ceramic tube. The ceramic tube provides excellent insulation and isolation, ensuring that the ignition rod discharges only in a specific area. The ceramic tube can withstand multiple rapid temperature changes without damage.

The outer surface of ceramic tubes usually has multiple groove-like corrugations. When sparks are generated between the terminal nut and the main metal, the high-voltage current will slide along the surface of the insulator. With this physical groove layer, it will prevent the generation of electric arcs.

Jinghui Ceramics has 10+ years of experience in the production of advanced ceramic products. Based on the characteristics of different fields, combined with different material properties and different technical requirements, we meet customers’ customization requirements and help customers’ career development with high-quality products and professional services.

Spark plug insulators need to operate stably under extreme conditions of high temperature, high pressure, and high voltage. Ceramic materials, especially high-alumina ceramics, can simultaneously meet the requirements of excellent electrical insulation, good thermal conductivity, high mechanical strength, and outstanding resistance to thermal shock and chemical corrosion. This is something that ordinary plastic or rubber insulating materials cannot do.

Our ceramic insulators are made from high-purity alumina raw materials and manufactured through an optimized sintering process, giving them a low coefficient of thermal expansion and high thermal conductivity. This means that during the frequent hot and cold cycles of the spark plug, the internal stress generated by the rapid temperature changes in the ceramic body is smaller, and heat can be transferred away more quickly, thus effectively resisting thermal shock, preventing cracks or breakage of the insulator, and ensuring the reliability of the spark plug.

You can carefully observe the surface of the ceramic insulator. A high-quality ceramic insulator should have a smooth and flat surface, uniform color, and no obvious spots, bubbles, or cracks. Furthermore, the junction between the insulator and the metal casing should be firmly sealed without any signs of loosening. Of course, these are only preliminary assessments; more precise performance indicators such as insulation strength and thermal shock resistance need to be verified using professional testing equipment.