Why Choose Silicon Nitride Tube

Silicon nitride tube is the preferred material for extreme applications such as high temperatures, corrosion, and high impact, mainly owing to its four irreplaceable advantages.

- Extreme temperature resistance: Operating temperature up to 1400°C in air.

- Super corrosion resistance: Resistant to strong acid (except HF), strong alkali and high temperature corrosion.

- Excellent thermal shock resistance: Withstands rapid cooling and heating temperatures up to 600°C.

- Extremely long service life: Taking the application of chemical acid transportation as an example, the life of silicon nitride tubes is 8 to 15 years, while that of Hastelloy is 3 to 5 years.

High Performance Silicon Nitride Tube Manufacturer

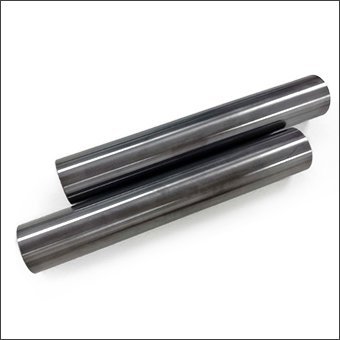

Jinghui provides silicon nitride tubes that meet international standards. They can work stably at high temperatures of 1400℃, have outstanding thermal shock resistance, extremely high mechanical strength and excellent chemical stability, and maintain stable performance in extreme environments.

We have advanced manufacturing equipment and experienced engineers and technical teams to help you find the solution that best suits your needs. Contact us now!

Product By Features

Jinghui’s silicon nitride tube is available in a variety of product forms, each with unique design and manufacturing requirements to meet the performance needs of different scenarios.

Protecting thermocouple sensors from high temperatures, corrosion or mechanical damage.

Used for plunger guiding and sealing in high pressure pumps or hydraulic systems.

Used for atmosphere protection or sample loading in high temperature furnaces.

Used for spraying and atomizing high temperature gases or liquids. Lighter than metal nozzles.

High resistivity and excellent high temperature resistance. Used in electrical equipment.

Simple structure, uniform inner and outer diameters, and easy to process and install.

With complex geometries (e.g. conical, spiral, flanged). Typical use is as special connectors.

High surface finish and low coefficient of friction. Suitable for precision matching scenarios.

An Innovative Choice for High-temperature Measurement of Molten Aluminum

In the non-ferrous metal smelting, casting and aluminum processing industries, accurate temperature measurement is the core link to ensure process stability and product quality. As the “armor” of the temperature sensor, the performance of the thermocouple protection tube directly determines the reliability and life of the measurement system.

Traditional metal thermocouple protection tubes (such as stainless steel or nickel-based alloys) are prone to failure in the high-temperature and corrosive environment of molten aluminum, while silicon nitride thermocouple protection tubes have become an irreplaceable cutting-edge choice in this field due to their excellent performance. The following are its core advantages and technical value in high-temperature measurement of molten aluminum.

- Resistant to high temperatures and thermal shock, and no fear of extreme working conditions

The temperature of molten aluminum is usually between 660℃ and 800℃, but in some processes (such as aluminum alloy addition or refining), the temperature may be as high as 1000℃ or more. Silicon nitride ceramics can withstand high temperatures of 1400℃ for a long time, and will not crack even if they are rapidly cooled from 800℃ aluminum liquid to room temperature. The service life of silicon nitride tubes is more than 3 times longer than that of metal tubes, which completely solves the problem of probe failure caused by thermal stress.

- Resistant to corrosion and pollution, ensuring accurate measurement

The corrosion of the metal tube by molten aluminum will cause measurement drift, while silicon nitride ceramics are almost completely inert, with a dense surface without pores, which can effectively block the penetration of molten aluminum and prevent the thermocouple wire from being contaminated or short-circuited. In addition, in the refining process, silicon nitride can also resist the corrosion of molten salts (such as NaCl-KCl mixed salts), extending the life of the protection tube by 3-5 times.

- Ultra-high strength and wear resistance: to cope with harsh mechanical environments

During the stirring, pouring or transmission of molten aluminum, the protection tube may be subjected to mechanical impact or wear. The bending strength of silicon nitride tube is 5 times that of stainless steel, and its hardness is second only to diamond, which can effectively resist mechanical damage. For dynamic working conditions such as continuous casting production lines, the durability of silicon nitride tubes significantly reduces the frequency of equipment downtime.

- Customized design: to meet diverse industrial needs

For the special needs of molten aluminum temperature measurement, silicon nitride tubes can provide a variety of customized designs:

- Size and shape: Customize the inner and outer diameters according to the size of the thermocouple or sensor to optimize heat conduction and response speed.

- Surface treatment: Reduce surface roughness through polishing or coating technology to reduce the adhesion of molten aluminum.

- Structural optimization: The integrated sealing end design can prevent aluminum liquid from penetrating; the threaded or flange interface is convenient for quick installation and replacement.

If you are looking for high-performance temperature measurement and protection solutions, please contact us for more technical support and customized services!

The maximum operating temperature of silicon nitride tubes can reach 1400℃. In an inert gas or vacuum environment, the operating temperature can even reach 1600℃.

The thermal shock resistance of silicon nitride tubes is at the top level among engineering ceramics. It can withstand a temperature difference of 600℃, thanks to its low thermal expansion coefficient (3.0~3.2×10⁻⁶/℃), high thermal conductivity (20W/m·K) and high fracture toughness (6-7MPa·m¹/²).

The price of silicon nitride tube is relatively high, mainly due to:

- High raw material cost: The preparation process of high-purity silicon nitride powder is complicated.

- Complex manufacturing process: High-temperature sintering and precision machining are required.

- High performance requirements: In order to meet high strength, high temperature resistance and other properties, the manufacturing process needs to be strictly controlled.

- Special application areas: Mainly used in high-end industries, with relatively small demand.