Core Machining Capabilities

We have been deeply involved in precision ceramic machining for many years and have accumulated extensive experience. Our core machining capabilities are as follows.

- General Tolerance: Our best level is controlled within 0.01mm.

- Geometric Shape and Positional Tolerances: Roundness < 0.0005mm, parallelism < 0.002mm.

- Surface Roughness: Mirror polishing achieves a surface roughness (Ra) of 0.02 μm.

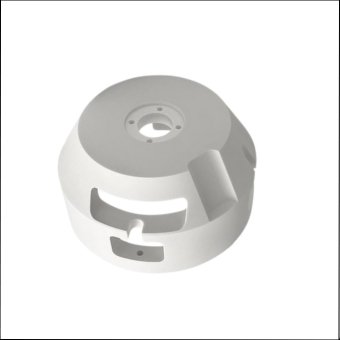

- Machinability: Capable of processing complex structures such as holes and grooves. Hole diameter accuracy up to 0.003mm. Min. groove width down to 0.2mm.

Your Reliable Partner in Precision Ceramics

Jinghui customizes precision ceramic parts according to your drawings. Through high-precision machining technology and comprehensive quality control, we precisely shape high-performance advanced ceramic materials into the complex geometries you require. From raw material inspection and production process monitoring to finished product testing, we implement strict quality standards at every stage.

Our technical strengths include:

1. High Precision and Consistency: By integrating multiple technologies and equipment while rigorously controlling process parameters, we effectively ensure dimensional accuracy and shape consistency.

2. Complex Shape Machining Capability: Our extensive machining experience allows us to accurately anticipate production challenges during the design phase of the production process. Using near-net-shape forming technology, we produce precision ceramic blanks close to the final part geometry, significantly reducing subsequent machining requirements.

3. High Flexibility: The demand for precision ceramic products often involves diverse varieties and small batches. Our flexible production scheduling effectively supports your requirements.

If you need precision ceramic parts, welcome to choose Jinghui as your partner.

Product By Applications

Precision ceramic parts are generally customized to your specific needs. We currently offer the following categories of precision ceramic products: semiconductor ceramics used in wafer fabrication and process equipment and in wafer handling and transport; medical ceramics used in medical devices and instruments; clean energy ceramics used in industries such as solar, wind, and hydrogen energy, as well as energy storage.

Precision Secondary Machining of Ceramic Parts

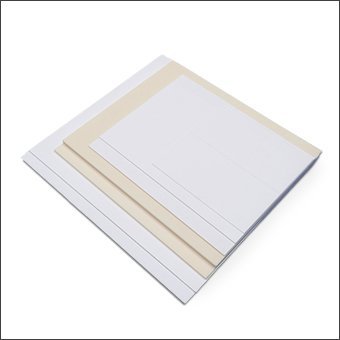

The post-processing of ceramic parts can be carried out using different processing methods depending on factors such as the shape of the ceramic, processing precision, surface roughness, processing efficiency, and processing cost.

External cylindrical surface, internal cylindrical surface, flat surface, formed surface, thread, tooth surface

Inner hole

External cylindrical surface, internal cylindrical surface, flat surface, grooved surface, spherical surface

External cylindrical surface, internal cylindrical surface, flat surface, formed surface, thread, spherical surface

Flat surface

Thickness below 3mm

Full-process Quality Control

We are an ISO 9001 certified company, and we implement integrated and strict control over the entire production process. From raw materials to manufacturing to shipment, every stage of production undergoes multiple inspection procedures—including incoming material inspection, first article inspection, self-inspection, mutual inspection, patrol inspection, and final inspection—to ensure quality compliance.

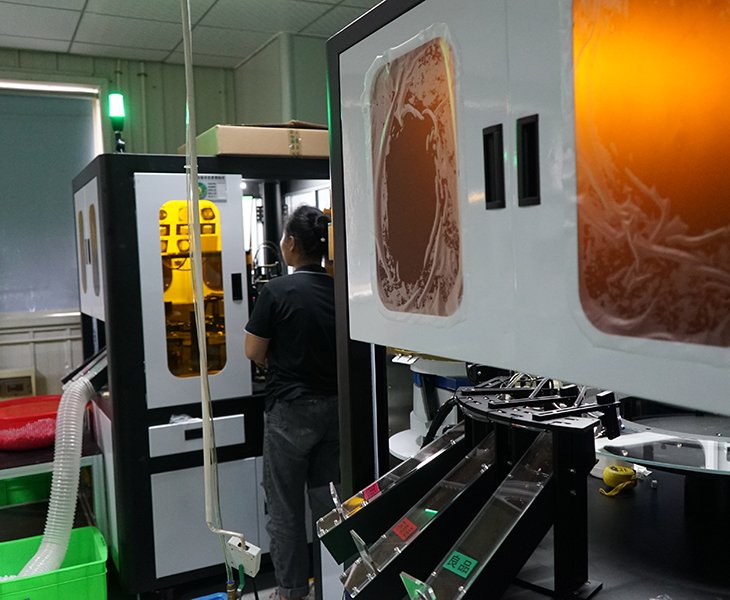

High-precision Machining Equipment

We are equipped with high-precision machining equipment such as CNC lathes, grinders, milling machines, drilling machines, polishing machines, and cutting equipment. We select appropriate equipment and machining technologies based on the requirements of the ceramic parts, ensuring both production efficiency and high-quality machining. For example, in grinding, the processes we commonly perform include flat grinding, cylindrical grinding, internal grinding, and centerless grinding.

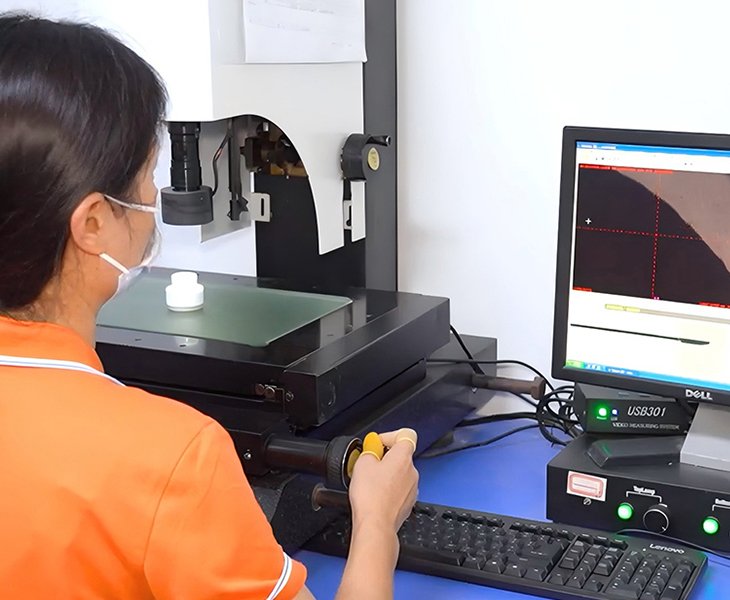

High-precision Testing Instruments

We are equipped with high-precision testing instruments such as electron microscopes, optical measuring machines, coordinate measuring machines, height gauges, surface roughness testers, densitometers, laser grain analytical instruments, coating thickness gauges, mechanical strength testers, and resistance meters. These instruments can accurately measure the dimensions, surface quality, mechanical properties, and other parameters of ceramic parts, ensuring that products meet design requirements.

Ceramic Material Properties

The four ceramic materials we most commonly use are alumina (Al2O3), zirconia (ZrO2), silicon nitride (Si3N4), and aluminum nitride (AlN). Their material properties are provided for your reference.

1. Mechanical Properties

| Property | Unit | 99.5% Al2O3 | 99% Al2O3 | 96% Al2O3 | 85% Al2O3 | 75% Al2O3 | 3Y-TZP | MSZ | AlN | Si3N4 |

| Density | g/cm3 | ≥3.9 | ≥3.8 | ≥3.65 | >3.4 | 3.2~3.4 | ≥6.0 | ≥5.72 | 3.3 | ≥3.2 |

| Flexural Strength | MPa | ≥350 | ≥310 | ≥280 | ≥220 | ≥200 | >800 | ≥750 | ≥310 | ≥700 |

| Modulus of Elasticity | GPa | 370 | 350 | 303 | 221 | 200 | 200 | 200 | 310 | 290~310 |

| Poisson’s Ratio | / | 0.22 | 0.22 | 0.2~

0.25 |

0.22 | 0.2 | 0.30 | 0.31 | 0.21 | 0.25 |

| Vickers Hardness | HV | ≥1570 | ≥1520 | ≥1380 | ≥1100 | ≥1000 | 1230 | 1070 | 1040 | 1420 |

| Compressive Strength | MPa | ≥2240 | 2160 | 2068 | 1930 | 2000 | 2500 | 1750 | 2100 | 2500 |

| Tensile Strength | MPa | 262 | 248 | 206 | 155 | <100 | 900~

1200 |

390 | 300~

450 |

600 ~

1000 |

| Fracture Toughness | MPa·m1/2 | 4~5 | 4~5 | 4~5 | 3~4 | 2.5~3.5 | 6.5~8 | 11 | 3 | 6~7 |

2. Thermal Properties

| Property | Unit | 99.5% Al2O3 | 99% Al2O3 | 96% Al2O3 | 85% Al2O3 | 75% Al2O3 | 3Y-TZP | MSZ | AlN | Si3N4 |

| Max. Service Temperature

(Non-loading) |

℃ | 1700 | 1600 | 1500 | 1200~

1400 |

1100 | 1500 | 1500 | 1200 | 1400 |

| Thermal Shock Resistance | ΔT (℃) | ≥200 | ≥200 | ≥220 | ≥200 | ≥200 | >300 | ≥350 | 700 | 600 |

| CTE (Coefficient of Thermal Expansion) @ 20-800℃ | 1×10-6/℃ | 6.5~8 | 6.2~8 | 6.5~8 | 5~8 | ≤6 | 9~11 | 10~10.5 | 4~6 | 3~3.2 |

| Thermal Conductivity @ 20℃ | W/(m·k) | 30 | 29 | 24 | 16 | 15 | 3 | 2.2 | 170~230 | 20 |

| Specific Heat @100℃ | 1 x 10-3 J/(kg·K) | 780 | 780 | 780 | 780 | 780 | 460 | 400 | 720 | 650 |

3. Electrical Properties

| Property | Unit | 99.5% Al2O3 | 99% Al2O3 | 96% Al2O3 | 85% Al2O3 | 75% Al2O3 | 3Y-TZP | MSZ | AlN | Si3N4 |

| Dielectric Constant | (E) | 9.7 | 9.6 | 9.4 | 8 | 8 | 29 | 28 | 8~9 | 7~8 |

| Dielectric Loss (tanδ) @ 1 MHz | / | 0.0001~ 0.0003 | 0.0002~ 0.0006 | 0.001~ 0.003 | 0.003~ 0.008 | 0.005~ 0.015 | 0.001~ 0.005 | >0.01 | 0.0001~ 0.0005 | 0.001~ 0.003 |

| Dielectric Strength | KV/mm | ≥18 | ≥17 | ≥15 | ≥10 | ≥8 | 9 | 9.4 | ≥17 | 13 |

| Volume Resistivity | Ω·cm | 1*1014 | 1*1014 | 1*1013 | 1*1013 | 1*1012 | 1*1013 | >1*1013 | >1*1013 | >1*10 |

Related Products

Ceramic machining refers to the use of a series of precision machining techniques to transform sintered high-performance ceramic materials (such as alumina and zirconia) into components that meet specific shape, dimensional, and surface requirements.

When directly sintered ceramic parts cannot meet precise tolerances, or when post-sintering warping requires correction, we perform machining on the sintered ceramics.

Due to ceramics being hard and brittle, machining them is no easy task. Improper processing can easily lead to microcracks and fractures.

Machining ceramics is a precision process that requires mastery of skilled techniques and careful monitoring of the machining process.

The precision and surface finish of ceramic parts are not determined by a single factor. They are the result of the combined effects of multiple factors, such as material properties, part geometry, manufacturing process, and budget.

Provide your drawings or requirements, and our engineers will evaluate them and recommend the most cost-effective and reliable manufacturing solution.

The materials commonly used in precision ceramics are aluminum, zirconia, silicon nitride, and aluminum nitride.

The choice of material depends on your specific working conditions. Below is a quick selection guide for your reference. We can also make recommendations upon request.

1. Seeking cost-effectiveness and corrosion resistance/insulation → Choose alumina.

2. Requiring high toughness (shatter resistance) or biocompatibility → Choose zirconia.

3. Facing high temperatures, thermal shock, high speeds, or demanding ultra-long service life → Choose silicon nitride.

4. Core requirement is efficient heat dissipation (with insulation) → Choose aluminum nitride.

Delivery time is related to the complexity of the parts, materials, and process requirements. Here is our approximate timeline.

1. Prototyping Stage

Simple standard parts: About 2-4 weeks.

Medium complexity parts: About 4-6 weeks.

High complexity/Initial production: About 6-8 weeks or longer (including design collaboration and multiple trial productions).

2. Mass Production Stage

After sample confirmation, our standard lead time for mass production orders is generally 4-8 weeks. The specific lead time depends on the order quantity and production capacity schedule.

We support your needs during the product development and validation phases. For larger products, the minimum sample quantity can be 1 piece. But if the size is small, producing a single sample is difficult and costly. Therefore, we will have a MOQ requirement (the specific quantity is determined based on demand).

The MOQ for bulk orders needs to be specifically assessed, but generally, the order amount should be no less than USD 150.