Reliable Metallized Ceramic Fabrication

- Seasoned and Innovative engineering & production team

- Selected and strictly controlled ceramic materials

- Develop & formulate ceramic metallization paste in-house

- The state-of-the-art ceramic shaping and metallizing equipment

- Rigorous and tightened inspection criteria for every batch

- Advanced bonding strength and gas-tightness test instrument

Expert Metallized Ceramics Factory in China

If you’re looking for a manufacturer capable of producing high-quality metallized ceramic components or hermetic ceramic-to-metal assemblies, you’ve come to the right place.

Since 2008, Jinghui has been specializing in the production of custom metallized ceramics. We possess in-house metallization capabilities, allowing us to apply ceramic metallization technology to flat, cylindrical, and various complex-shaped ceramic parts according to your requirements.

In terms of base material selection for metallized ceramic components, in addition to conventional high-purity alumina, we also offer various base materials such as aluminum nitride and zirconia to meet your different needs. Furthermore, we can also provide ceramic-to-metal brazed assemblies if required.

These metallized ceramic products feature excellent metallization layer adhesion, electrical conductivity, reliability, durability, and high-temperature stability. They are very suitable for use in vacuum interrupters, vacuum feedthroughs, power grid tubes, gas discharge tubes, etc.

Please feel free to contact us to discuss potential collaborations.

Our Metallized Ceramic Products

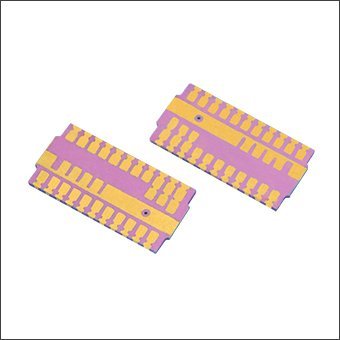

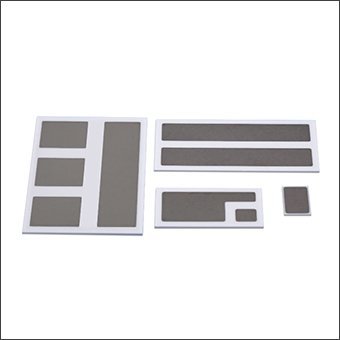

Common product forms of metallized ceramics include metallized ceramic tubes/cylinders, metallized ceramic rings/washers, metallized ceramic plates/discs/substrates, and various metallized ceramic structural components. The specific areas where metallization is applied vary depending on the product and its application.

Tubes are the most common form of ceramic metallized parts, generally with both ends metallized.

A customized metallization pattern on ceramic plates is typically used as an electrical conductor.

Metallized ceramic rings used as electrical insulators are usually made from 95% or 99% alumina.

It leverages the excellent vacuum airtightness achieved by brazing ceramics and metals.

These ceramic cylinders are used in high-voltage, high-current applications or in applications requiring vacuum-tightness.

Various simple or complex patterns can be silk-screened onto ceramic substrates, primarily used as PCB bases.

Metallized washers are typically used as intermediate parts for brazing ceramics and metals.

We manufacture a wide range of custom metallized ceramic components for various vacuum electronics applications.

Typical Applications

Metallized ceramic products are often used in critical applications where insulation, sealing, and conductivity are required to coexist in harsh environments, such as vacuum electronic devices and high-voltage switches.

Carries high voltage or current through a vacuum wall to a vacuum device.

A sealed ceramic tube that protects circuits from power surges

an electromechanical device that switches high voltage circuits.

It converts electrical input power into X-rays, are used in medical imaging and other applications.

A switch that controls the flow of electricity in an electric vehicle (EV).

To separate electrical contacts and extinguish the resulting arc.

Used to measure winding temperature of large Motors, Generators, etc.

The Importance of Metallized Ceramics for Vacuum Electronic Devices

Metals are highly conductive and weldable, but they are not insulating and outgas at high temperatures. Ordinary ceramics are insulating, high-temperature resistant, and vacuum-tight, but they are not conductive or weldable.

Metallized ceramics, however, combine the advantages of both, achieving both insulation and conductivity, sealing and connectivity, and both heat resistance and thermal conductivity. Without it, vacuum electronic devices like high-power traveling-wave tubes and magnetrons could not operate stably for tens of thousands of hours under harsh conditions.

The importance of metallized ceramics for vacuum electronic devices is primarily reflected in the following aspects.

What We Can Do

1. Optional Materials:

94~99% alumina, aluminum nitride, and zirconia

2. Available Shapes:

Tube, cylinder, plate, ring, rod, and various customised structural parts

3. Size Capability:

OD from φ1.0mm to φ200mm, max. length 500mm

4. Nominal Size Tolerance:

Outer diameter can be ±0.01mm, inner diameter can be ±0.05mm, and overall length can be ±0.01mm

5. Available Surface Finishes:

Glazing, polishing, sandblasting

6. Joining Types of Metallization:

- Ceramic body + silver (Ag)

- Ceramic body + molybdenum (Mo/Mn) + nickle (Ni)

- Ceramic body + tungsten (W) + nickle (Ni) + gold (Au)

7. Ceramic to Metal Brazing Capability:

We can braze ceramics with stainless steel, copper, kovar, and invar.

Complete Production Capability

With our selection of ceramic forming machines, parts of any size can be shaped in-house to ensure dimensional consistency. In addition, the sintered ceramic components can be machined with micro-level dimensional tolerance. What’s more, we have our own metalizing & electroplating production line. Integrated production enables cost control and helps us shorten lead times to meet our clients’ urgent needs.

Stringent Quality Control

1. Incoming quality checks for new-arrival raw material in each batch must be conducted before production.

2. The IPQC is performed throughout the production flowchart, and OQC inspection must be conducted.

3. Visual inspection of 100% ceramic parts will be conducted to identify any with black/yellow dots, chipping, or contamination.

4. The brazing strength and air hermeticity tests for each order will be conducted before shipment to the end customers.

Why Choose Us

We always consider what our customers expect and do only what they truly care about. Born for high-quality metallized ceramics and let’s quality to be measurable and quantifiable.

- Custom-built service availability

- R&D to bulk production capability

- Consistency guarantee of quality

- One-stop shopping supply ability

- Fast response to any inquiries within 12 hours

- Attentive and prompt after-sales service

- Affordable mold charge and competitive unit cost

- Low minimum order quantity (MOQ) request

- Fast turnaround times with flexible delivery times

- Competent help and assistance for specialized problems

- Free technical & design consultation service

- Reliable partner for innovation and sustainability

More About Our Metallized Ceramics

Jinghui provides customized metallized ceramics for applications such as power feedthroughs, gas discharge tubes, power grid tubes, X-ray tubes, and vacuum interrupters.

Alumina ceramics (Al2O3) are our most commonly used base material; other materials, such as zirconia (ZrO2) and aluminum nitride (AlN), are available upon request.

Our most frequently used metallization process is thick-film Mo-Mn metallization. The ceramic metallization process enables ceramic components to possess both insulating and conductive properties. Subsequently, if required, the metallized ceramic parts can be brazed to metal components using a ceramic-to-metal brazing process.

- Technical Data

- Core Advantages

- Metallization Locations

- Main Applications

1. Base Material Properties

| Property | Unit | 94.4% alumina (Al2O3) | 96~99% alumina (Al2O3) | 3YSZ zirconia (ZrO2) | Aluminum nitride (AlN) |

| Density | g/cm3 | ≥3.60 | 3.65~3.80 | ≥6.00 | 3.30 |

| Vickers Hardness | HV | ≥1334 | 1380~1520 | 1230 | 1040 |

| Flexural Strength @ 25°C | MPa | ≥270 | 280~310 | >800 | ≥310 |

| Thermal Conductivity @ 25°C | W/(m·k) | 22 | 24~29 | 3 | 170~230 |

| CTE (Coefficient of Thermal Expansion) | 1×10-6/℃ | 5~8 | 6.5~8 | 9~11 | 4~6 |

2. Key Parameters of Metallization Layer

| Types of Ceramic Metallization | Mo-Mn and W |

| Typical Thickness of Metallization | Mo-Mn: 10~40 µm, W: 10~30 µm |

| Types of Metal Plating | Nickle (Ni), silver (Ag), and gold (Au) |

| Typical Thickness of Metal Plating | Ni: 2~6 µm, Ag: 3~5 µm, Au: 0.1 µm |

| Ceramic Metallization Method | Hand painting, silkscreen, spray, and needle |

3. Precision and Appearance

| Dimensional Tolerances | ±1% or custom |

| Surface Roughness | Ra≤1.6μm |

| Parallelism/Flatness | Custom |

Through advanced ceramic metallization technology, our metallized ceramic products achieve a high-strength and high-density bond between the ceramic base and the metallized layer. This not only provides excellent mechanical adhesion and superior heat dissipation performance, but also lays a reliable foundation for subsequent ceramic-metal sealing.

1. Extreme Environment Adaptability

- High temperature resistance (>800℃)

- Corrosion resistance (acids, alkalis, molten metals)

- No gas release under high vacuum conditions

2. Electrical and Packaging Advantages

- Enables hermetic packaging

- Low RF loss (for high-frequency applications

3. Ideal Appearance Quality

- Uniform metallization layer, metal coating, and thickness

- Free of cracks, impurity spots, burrs, and contamination

We can apply metallization to the end/side faces of cylindrical ceramic components, through-holes in ceramic plates or rings, specific and discontinuous micro-regions on ceramic surfaces, and the flat surfaces of ceramic substrates. Metallized areas exhibit electrical conductivity, solderability, and enhanced mechanical bonding strength.

Metallized ceramics combine the insulation and heat resistance of ceramics with the conductivity of metals, and are widely used in many high-tech fields. The following are their main application areas:

- Metallized ceramics for vacuum feedthrough

- Hermetically sealed tubing for power electronics and electric vehicle applications

- High temperature and corrosion resistant sensor

- Metalized ceramic substrates used as insulating and heat-dissipating substrates for power electronic modules

Depositing a metal layer onto a specific region of ceramic components first, then bonding the metallized layer tightly to the ceramic surface after high-temperature curing inside a vacuum furnace. These kinds of crafted parts are called metalized ceramics.

The essence of ceramic metallization is to achieve a reliable connection between ceramic and metal materials via brazing, thereby integrating the advantages of both materials, or to meet vacuum-sealing requirements in some devices.

Sure!

We can make custom metalized ceramic parts per your specifications or real samples. The size, geometry, material, and metallization type for ceramic components can all be customised.

The application of metallized ceramics for electronics mainly covers:

- Semiconductor packaging and circuit interconnection, such as IC packaging and electronics case tubes.

- Power electronics and thermal management, including IGBT modules, laser diodes, and high-power LEDs.

- High-frequency communication and radio-frequency components, such as RF windows, microwave components, and filters.

- Advanced manufacturing and cutting-edge technologies, such as sensors, various high-voltage and high-current vacuum devices, and 3D printing.

It’s an art-of-the-state manufacturing process that deposits metallization onto the surface of advanced ceramics via screen printing, hand painting, spray, needle, and vacuum sputtering.

Molybdenum manganese (Mo Mn) slurry mixed with evenly distributed agents such as Ti, Zr, Fe, SiO2, and CaO will be coated onto the ceramic surface. The treated ceramic parts will be sintered at 1450~1600℃ to form a tightly bonded Mo/Mn layer on the ceramic body. This is called Mo Mn metallization, which is the most typical ceramic metallization for advanced ceramics.

The difference in thermal expansion coefficient between ceramics and metals may lead to stress concentration and peeling between ceramics and metals, thus affecting the adhesion and stability of the metallization layer.

Moreover, ceramics usually have high chemical stability and inertness, which makes it difficult for metal materials to bond well with them.

In addition, if the metallization process is not well controlled, it will lead to quality problems of the metallization layer, such as poor bonding, brittleness, cracks, etc.

Metal-ceramic packages with poor airtightness are prone to leakage during use, resulting in unstable performance of the device or system, or even malfunction. We believe that the following reasons may cause leakage.

1. Ceramic problem: (1) Ceramic cracking; (2) Whether the design structure of the ceramic is conducive to reducing stress.

2. Metallization problem: Cracking, blistering, sinking, oxidation, or peeling of the metallization layer, etc.

3. Brazing problem: (1) The thermal expansion coefficients of ceramic and soldering parts are inconsistent; (2) The fixture does not match the product; (3) Human operation problem; (4) Solder problem.

Yes! We accept sample orders at the initial cooperation stage or for an R&D case.

There are 2 cases:

- For ceramic parts with a simple design, the delivery will be in 6~7 weeks by express.

- On the other hand, the delivery will be 8~9 weeks when the ceramic parts have a complex shape as well as tight dimensional tolerance.