Product Overview

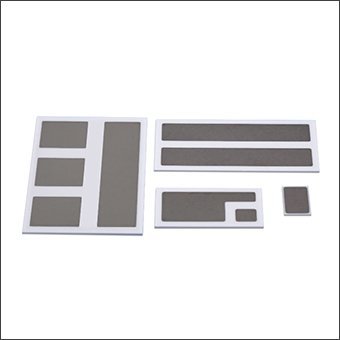

When your circuit design faces harsh challenges of high voltage, high temperature, or ultimate reliability, a common insulator can be the weakest link. Our precision-customized metallized ceramic insulators, featuring permanent ceramic-to-metal bonding via co-firing technology, build a reliable performance barrier for your high-end applications.

A large part of our metallized ceramics are metallized ceramic insulators, which integrate metal coatings (Ag, Cu, or Ni) onto advanced ceramics (e.g., alumina, AlN, or zirconia) to achieve synergistic enhancement in electrical insulation and mechanical robustness. They are engineered for hermetic sealing (<10⁻⁹ Torr), high-voltage isolation (>20 kV), and thermal management (conductivity >200 W/mK).

Metallized Ceramic Insulator Key Features

Every drawing you provide is a dedicated project to us. From assessing structural feasibility and simulating stress distribution to producing first articles and providing detailed test reports, our project manager accompanies the entire process. Making customization no longer synonymous with long lead times and uncertainty.

We customize various products according to your requirements. These metallized ceramic insulators have several important features as follows:

1.Hermetic Sealing: Brazable metal layers (e.g., Mo-Mn or Ag-Cu) prevent gas leakage in vacuum chambers (<10⁻⁹ Torr).

2.High-Temperature Stability: Withstand 1,200°C (Al₂O₃) or 1,600°C (ZrO₂) in inert atmospheres.

3.Customizable Coatings: Ag for RF conductivity, Ni for corrosion resistance in acidic/alkaline environments.

We understand you need not just a component, but a solution that secures your product’s lifespan. Submit your requirements now, and receive a detailed evaluation and a preliminary quote within 24 hours.

Product By Features

The products we provide have different features, and the representative products are as follows:

Used for new energy with excellent thermal stability and aging resistance.

Used for high-voltage power grids and excellent thermal stability.

Used for new energy with good strength and good sealing.

High voltage resistance, good isulation and excellent impact resistance.

Good performance of high insulation and aging resistance.

Used for energy storage with good strength and heat dissipation.

Metallized ceramics excel in vacuum environments due to zero outgassing properties and ultra-high temperature resilience. For instance, Al₂O₃ insulators with Mo-Mn metallization maintain seal integrity at 10⁻⁹ Torr, while PTFE plastics degrade above 260°C and release volatile compounds. In particle accelerators, ceramic-metal interfaces reduce contamination risks by 90% compared to polymer seals. Additionally, their coefficient of thermal expansion (CTE) matches critical metals like Kovar (5.3×10⁻⁶/°C), preventing thermal stress cracks during rapid temperature cycling.

Ag-coated AlN insulators achieve thermal conductivity >200 W/mK, dissipating heat 5x faster than epoxy isolators. In IGBT modules, this reduces junction temperatures by 30°C, extending lifespan by 3 years. The metal layer enables direct active metal brazing to copper heat sinks, minimizing interfacial thermal resistance (<0.1 K/W). For high-frequency RF devices, Ag’s electrical conductivity (6.3×10⁷ S/m) also reduces signal loss by 15% at 10 GHz compared to Ni coatings.

Yes. Laser cladding or electroless Ni replating can restore localized damage. However, extensive delamination requires full stripping via acid etching (e.g., HNO₃ for Ag), followed by surface reactivation.