Primary Strengths

- Biocompatibility: Design for harmony between synthetic material and living tissue.

- Precision: Machined to micron-level dimensional tolerances and consistency

- Electrical Insulation: A perfect dielectric barrier ensuring absolute electrical safety

- Durability: Unmatched strength and wear resistance, ensuring lifelong performance

- Chemical resistance: Inert in even the harshest biological environments.

- Vacuum tightness: Hermetically sealed for ultra-high vacuum integrity

Precision You Can Trust, Performance They Rely On

Our factory specializes in a wide range of high-performance medical ceramics—crafted from engineered alumina, zirconia, and silicon nitride—that deliver the critical properties your advanced equipment demands: exceptional wear resistance, superior electrical insulation, and uncompromising chemical stability. These aren’t just parts; they are the foundation of accuracy and longevity in sensitive analytical environments.

We transform these advanced materials into precision reality. Every component is custom-manufactured to your exact specifications, ensuring perfect integration into your designs. Our commitment extends beyond manufacturing. Every batch undergoes sampling inspections exceeding industry standards to ensure critical dimensions and functions meet specifications, guaranteeing the reliability of your designs.

Partner with us to build the future of diagnostics. Let our expertise in precision ceramics become your competitive edge in creating devices that are not only more precise but also more durable and trusted worldwide. Contact us today to discuss how we can tailor a solution for your next highlighted instrument.

Product By Applications

Medical ceramics enable medical devices and instruments to achieve greater stability, lab analysis accuracy, and longer service life.

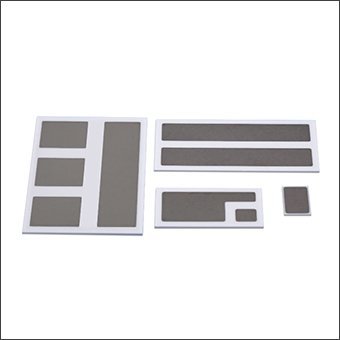

A regular precision-engineered ceramic component for blood collection devices

Featured by their excellent dielectric insulation, thermal stability, and biocompatibility

Widely used in the pump cavity to efficiently direct light from flashlamps to the laser rod

It provides hermetic seals that combine the ceramic’s insulation with the conductivity of metals.

A Quick Guide to Medical Ceramics

What are medical ceramics?

Medical ceramics are precision parts or sub-assemblies made from advanced ceramic materials possessing biocompatibility. Unlike the metals and special plastics used in traditional medical devices, medical ceramics combine high mechanical strength, wear resistance, chemical insulation, aging resistance, and electrical insulation. They can further optimize the performance of medical devices, improve the accuracy of lab testing and analysis results, and extend the lifespan of medical equipment, bringing more possibilities for innovation and breakthroughs in medical devices.

Key properties

- High voltage electrical insulation: They can withstand dozens of kilovolts, especially alumina-glazed components

- Abrasion resistivity: Excellent abrasion resistance with a much lower wear rate than metal in biomedical applications

- Superior chemicalstability: Strong chemical inertness and corrosion resistance in harsh bodily fluids

- High Fracture toughness: Its high toughness breaks through the perception of ceramic brittleness in your mind

- Hermeticity: An extremely dense ceramic body with zero porosity is an ideal vacuum protective tube housing

- RF transparency: The distinct property of medical ceramics enables clear RF signals for precise imaging

Typical applications

1. Lab Analytical Equipment: Biochemical/immunological analyzer, gene sequencer

2. Blood collection: blood analyser, in vitro diagnostic analysis instruments, blood separator machine

3. Medical imaging: X-ray tube, CT scanner, nuclear magnetic resonance imaging(NMRI)

4. Laser devices for medical: Ceramic reflector for laser, heat sinks, ceramic-metal sealing assembly

5. Medical implants: artificial hip joint, total knee prosthesis, ceramic crowns, ceranucbridges

6. Surgical tools: wear parts for endoscopic instruments ,insulating components, robotic end effectors,

The application of advanced ceramics in medical equipment is essentially aimed at resolving the key contradiction that makes it impossible to achieve the same performance from metals and polymers. Therefore, there are numerous types depend on their unique properties:

- High strength and wear resistance: Orthopedic implants, Dental restorations, Minimally invasive and precise surgical tools, Key auxiliary of medical devices

- High-voltage electrical insulation: ceramic insulator / isolators in X-ray tube, CT devices, BEED cutter head in electrosurgical surgical instruments

- High thermal conductivity: Various aluminum nitride substrate, alumina ceramic substrate or Multilayer ceramic substrate in power mould inside the CT, MRI scanners

- Tight tolerance dimensions: Endoscope tip, ceramic hollow micro needle, microwave ablation tube for Minimally invasive surgical instruments

- Ideal vacuum hermetic: Wildly used on ceramic to metal brazed assemblies within X-ray tubes, CT detectors, vacuum laser systems

When evaluating the types of advanced ceramic materials that can be used in medical devices, the following factors must be considered: biological compatibility and safety, Physical and mechanical properties, Chemistry and Long-Term Stability, Feasibility of manufacturing, and Sustainability & Cost Efficiency.

Based on the above aspects, the mainstream ceramic material include alumina (al2o3), zirconia (ZrO2), aluminum nitride (AlN), silicon nitride (Si3N4) and hydroxyapatite (HA)

Yes, exactly.

We make use of our deep-seated mold design capability, selection of ceramic shaping processes, precision machining capacity and ceramic-to-metal sealing technology, the ceramic components for laser equipment and imaging devices can be tailored in our site to reach your demanding needs.

To ensure consistent quality across batches, precise management of the entire supply chain from raw materials to finished products is conducted, including:

- Raw materials and front-end processes, such as raw material batch management, particle-size detection, and moisture content measurement of incoming ceramic material.

- Manufacturing and processing: automated production lines replace manual ones; ultra-precision engraving & milling machines are used (accuracy within ±0.001mm); process parameters and material properties are dynamically adapted.

- Quality Inspection and Standards: statistical process control (SPC); Intelligent online/offline inspection (e.g., coordinate measuring machine)

- Building system: establish a database of material properties and processes, and conduct process iterations based on data feedback.

Yes, sure!

To ensure the ceramic products meet the client’s technical specifications, we can support our customers by providing the first article inspection (FAI) with all necessary detailed documentation.

To ensure the safety and reliability of every medical ceramic component, we have established a digital traceability system covering the entire product lifecycle. This system strictly adheres to the requirements of the Medical Device Quality Management System, enabling precise, rapid traceability from raw materials to finished products through a management model of “one item, one code; full-process binding; and closed-loop data.”