Overview

“Glaze” is a thin glassy layer covering the surface of the ceramic body.Advantages of “glaze”:1. Improve the appearance quality of ceramic products: gloss, color, picture, etc. In industrial ceramics, it mainly improves the surface gloss and smoothness; 2. Improve product performance: mechanical strength, chemical stability, electrical insulation, anti-fouling, water permeability, heat dissipation capacity, etc.

The Data for Glass Vs Glaze

| Property | glass | glaze |

| Glass commonality | Refractive index, elastic modulus, hardness, etc. are the same in different directions; No fixed melting point and reversible; Glossy and hard; Dense texture, impermeable to liquids and gases. |

|

| Ingredients | Silicate | In addition to silicates, it contains borates, phosphates, and more aluminum oxide. |

| Uniformity | Homogeneous | Small amounts of gas inclusions, unreacted quartz crystals, and mineral crystals |

| Melting temperature | lower | higher than that of glass |

| Thickness | Base layer, thickness as required | Adhesion layer ,80~260um |

From the above data, we know that alumina is an important component of glaze, which can increase the adhesion of the embryo glaze and prevent the glaze from losing its gloss or becoming opaque.

Product Showcase

Among industrial ceramics, the products that need to be glazed are mainly ceramic tubes, ceramic insulators, textile ceramics and other products.

-

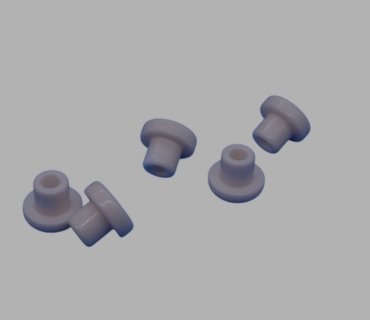

glazed ceramic eyelet

glazed ceramic eyelet -

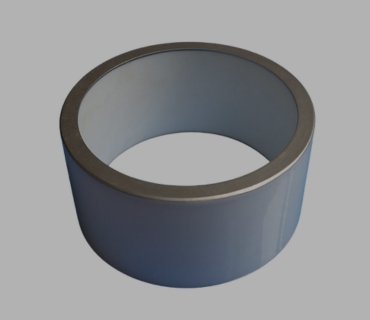

glazed ceramic bush

glazed ceramic bush -

glazed ceramic plate

glazed ceramic plate -

glazed ceramic tube

glazed ceramic tube -

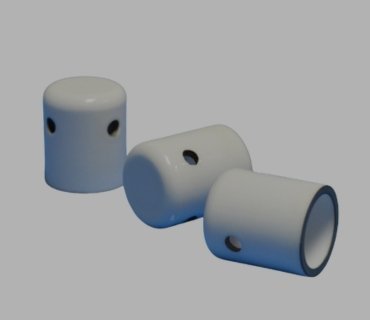

glazed ceramic holder

glazed ceramic holder -

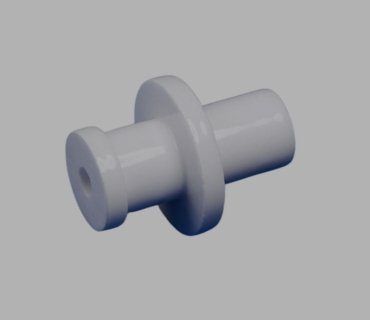

glazed ceramic isolator

glazed ceramic isolator

Glass Glazing for Advanced Ceramics

Glass glazing is a surface treatment process where a glass-based coating is applied to advanced ceramics (e.g., alumina, zirconia, or silicon carbide) to enhance their thermal stability, chemical resistance, and mechanical durability. The glaze forms a vitrified layer during high-temperature sintering (1,200–1,500°C), sealing surface pores and preventing environmental degradation. This technique is critical for components in aerospace, energy, and biomedical industries exposed to extreme conditions.

Key Process Steps

-

Glaze Formulation

-

Composition: Glazes typically contain SiO₂ (50–70%), Al₂O₃ (10–20%), and fluxing agents (e.g., B₂O₃, Na₂O) to lower melting points. Additives like ZrO₂ or Y₂O₃ improve thermal shock resistance.

-

Preparation: Raw materials are ball-milled into fine powders (<10 µm) and mixed with binders (e.g., polyvinyl alcohol) to form a slurry.

-

-

Application Methods

-

Spray Coating: Automated spray systems ensure uniform thickness (50–200 µm) for complex geometries like turbine blades.

-

Dip Coating: Immersing ceramics in glaze slurry, ideal for small, high-volume components.

-

Screen Printing: Precision patterning for electronic substrates or sensor surfaces.

-

-

Sintering

-

Temperature Profile: Gradual heating (5°C/min) to 1,400°C in oxidizing or inert atmospheres.

-

Phase Formation: Glass phase densifies, bonding with the ceramic substrate via diffusion.

-

-

Quality Control

-

Defect Detection: X-ray tomography or ultrasonic testing identifies cracks or voids.

-

Performance Testing: Thermal cycling (1,000°C ↔ room temperature) and corrosion resistance (acid/alkali immersion).

-

Applications

-

Aerospace: Thermal barrier coatings (TBCs) for engine components (e.g., SiC/SiC composites).

-

Energy: Sealing layers for solid oxide fuel cells (SOFCs) to prevent gas leakage.

-

Biomedical: Bioinert glazes for zirconia dental implants to reduce bacterial adhesion

Glass glazing enhances advanced ceramics by forming a dense, non-porous layer that blocks oxygen diffusion and chemical corrosion. For example, alumina components with SiO₂-B₂O₃ glaze show 40% lower oxidation rates at 1,200°C compared to uncoated samples. The glaze also reduces surface friction, improving wear resistance in industrial pump seals.

Choose glazes with high SiO₂ (≥60%) and Al₂O₃ (≥15%) for thermal stability. Additives like ZrO₂ (5–10%) mitigate thermal expansion mismatch. For aerospace TBCs, Y₂O₃-stabilized ZrO₂ glazes achieve thermal conductivity <1.5 W/m·K, outperforming traditional coatings.

Defects include pinholes (from trapped gases) and cracks (due to CTE mismatch). Solutions include optimizing sintering profiles (e.g., slow cooling at 2°C/min) and using nano-sized fillers (e.g., Si₃N₄) to refine microstructure.

Yes. Laser cladding or sol-gel recoating can repair minor defects. For severe damage, chemical etching (e.g., HF-based solutions) removes the glaze layer, allowing reapplication.