CKD Supply Advantages

Cost Control: Customers can purchase only consumable parts, resulting in replacement costs 60% lower than purchasing the entire machine.

Customization Flexibility: We support mixed-material solutions to accommodate varying material hardness requirements.

Quick Response: We maintain a wide inventory of standard parts, enabling rapid response.

Technical Independence: Customers can adjust assembly parameters (such as preload) to optimize grinding efficiency and energy consumption.

What is CKD for Grinder Mechanism

Ceramic burrs are our company’s primary business, primarily providing ceramic conical burr, ceramic flat burr and corresponding grinding core kits. Because particle grinders have diverse usage scenarios and various appearances, but their core functions and structures are generally similar, grinding core kits sometimes cannot meet customer needs. Some customers also require the CKD parts included in the kits. We have also enabled corresponding services to respond to these flexible and diverse needs. Generally, because the parts in these kits are not made of ceramic materials, we provide the corresponding production requirements to our partners for collaborative completion.

For some common parts, we maintain regular inventory, and for customized parts, we discuss production feasibility with our partners to do our best to meet customer needs. Our goal is to become the preferred choice for customers in China.

Product By Features

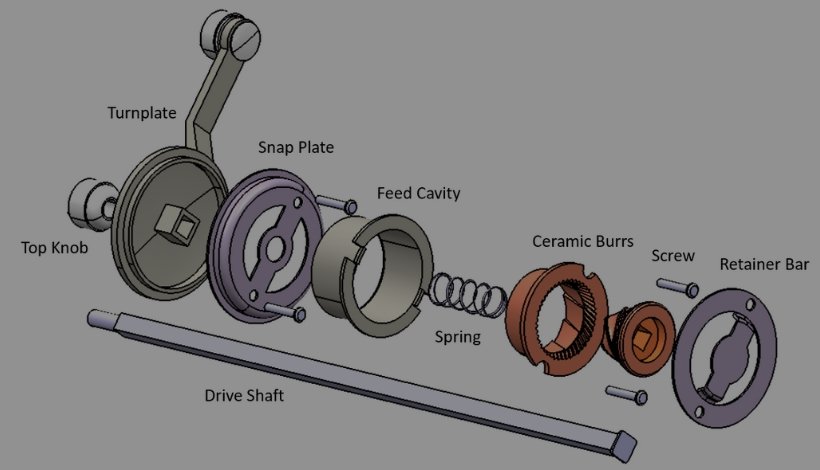

CKD parts for grinder mechanism vary in appearance and quantity depending on the kit. Some are common parts, such as springs, grinding cores, drive draft, and screws, and are available in stock. Other parts, such as retainer bar, feed gavity, top knob, and turnplate are custom-made and require custom orders. A small number of parts are available in stock. The following is a list of related parts.

The core parts of grinder, the material mostly is ceramic, but some customers require metal parts.

Placement area for grinding raw particles, mostly made of PPC material, and there are also custom-made metal.

Spring parts are generally universal parts with straight column shape, but some customers may customize the conical shape.

Placed at the bottom of the grinder, and can laser engrave the LOGO on it according to customer requirements.

Both a functional key and a decorative part, and there are many customizable shapes.

Used for manual rotation to control the grinding process, the rocker has different shapes.

Material is sus 304 or other metal, used to fix the outer teeth of the grinding core and the retainer bar.

Sus 303/316,Al6063, transmit external driving force to drive the rotation of the inner teeth.

CKD for Grinder Mechanism Application

Coffee Grinders:

The loose parts are compatible with high-end coffee grinders and other brands on the market, and the grinding core design ensures uniform coffee powder particle size.

Grinding Grinders for Kitchen Ingredients like Pepper and Salt:

The loose parts are compatible with cost-effective grinders, homemade grinders, and high-end brand grinders, providing flexible and lightweight compatibility.

Laboratory Milling Equipment:

The corrosion-resistant ceramic loose parts are used for grinding small batches of chemical raw materials in the laboratory to avoid metal contamination.

Medical Grinders:

The biocompatible ceramic grinding core is used for ultra-fine grinding of pharmaceuticals.

Alumina is suitable for common materials (coffee, spices), offering low cost and sufficient hardness. Zirconia is suitable for high-hardness materials (traditional Chinese medicine bones, engineering ceramics), offering greater impact resistance. Jinghui Technical Support can assist with selection.

Yes. We have dedicated personnel to quickly prototype and produce parts using gel casting, flash firing, or 3D printing. Some parts can be delivered in as little as seven days.

For ceramic grinding core parts, the minimum order quantity is 20 pieces. For other parts except ceramic grinding core, the minimum order quantity is 100 pieces. If it is for proofing, we can discuss it separately.