Jinghui Ceramic Tubes Rocket Your Business

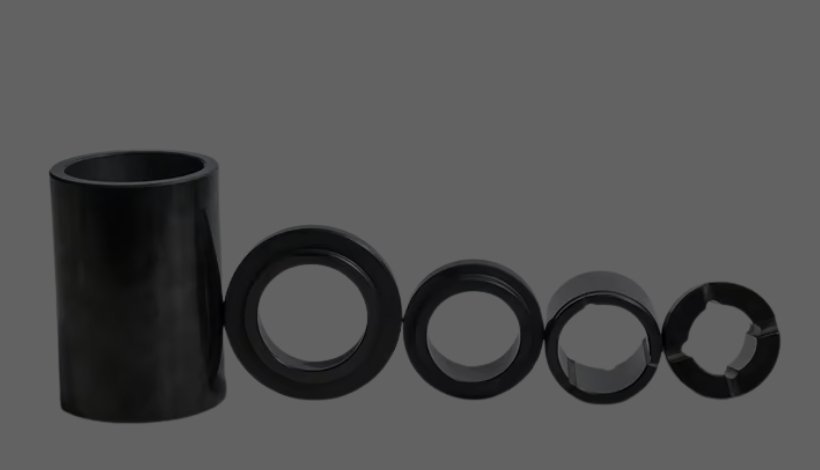

- A wide range of ceramic tubes in stock

- Different materials and customized shapes are available

- High-precision dimensions with ideal surface quality

- Various in-house secondary process for custom designs

- Competitive pricing and affordable mold charge

- Quick & flexible delivery caters to your expectation

Leading Ceramic Tube Manufacturer in China

Jinghui is a professional engineering ceramic tube manufacturer with 17 years of production experience. Based on the production of alumina and zirconia ceramic tubes, we also supply aluminum nitride, silicon nitride, and other composite ceramic tubes. The production process includes not only dry pressing, hot pressing, and isostatic pressing but also precision injection molding, combined with precision sintering technology above 1600℃ to ensure product density > 99%, thereby minimizing dimensional deviation and cracking problems.

As you know, ceramic tubes are the most common ceramic components in all technical ceramic industries. Therefore, in addition to standard round tubes, there is a high demand for customization in different industries and applications. To meet these needs, we can support not only various special shapes but also provide microtubes with a diameter of 0.5mm to large-size tubes with a diameter of up to 500mm. To ensure the accuracy of the product, the ceramic tubes are precision ground in the factory, or CNC machined, with a dimensional accuracy of 0.001mm.

So far, we have been serving over 500 customers from medical, green energy, semiconductors, and so on. We are still committed to making technology practical and creating value with experience. Therefore, we are not only your supplier, but also your partner. We look forward to your joining us.

By Material

By Features

By Applications

-

For Medical Equipment

For Medical Equipment -

For Semiconductor

For Semiconductor

Related Products

An Overview of Industrial Ceramic Tube

The industrial ceramic tube is different from traditional porcelain ones, it can be concisely concluded as follows:

- Materials Science

The core materials for industrial ceramic tubes are refined high-purity non-metallic oxides, nitrides, and carbides, including aluminum oxide(Al2O3), zirconium oxide(ZrO2), aluminum nitride (AlN), silicon nitride (Si3N4) and silicon carbide (SiC), etc. They are suitable for use in extremely harsh working environments, such as ultra-high temperatures, high wear, high humidity, strong corrosion, and high current and voltage applications.

- Engineering Applications

Ceramic tubes play an important role in the precision industrial system behind the scenes, such as they are used as a wafer transmission tube resistant to plasma corrosion in semiconductor equipment, as a sterile and high-temperature laser scalpel tubing in the medical field, and as a liquid injection tube resistant to lithium battery erosion in new energy batteries.

- Industry value

When they are used as ceramic thermocouple protection tubes, they can reduce downtime and maintenance times by 50%. When they are used as electrical insulation tubes, the operating voltage can be up to 100 kV. When they are used with a ceramic body in an X-ray tube, the vacuum density can reach 10-11 Pa.m3/s. Industrial ceramic tubing is an innovative component with exceptional properties. They overcome the inherent defects of metal and plastic and reconstruct the equipment economic model with super-high temperature resistance, wear resistance, good insulation performance, corrosion resistance, and so on.

- Manufacturing process

Different from the traditional cutting process of metal tubing, industrial ceramic tubes are made by pressing or extruding powder through advanced molding equipment, like dry pressing, isostatic pressing, and extrusion machines, and are high-performance functional parts with millimeter size obtained by nano-level sintering shrinkage control.

- Market Positioning

Industrial ceramic tubes are the “entry threshold” for high-end manufacturing. For example, in the fields of aviation, aerospace, semiconductor equipment, high-temperature smelting, etc., it has changed from an “optional option” to a “must-have option”.

Unlike traditional tubes and pipes, customized formulas of ceramic materials are needed to achieve designated and distinguished properties. Sometimes, polishing and metalizing treatments are needed to extend their applications.

- Sustainability

You may not be aware of the merits of industrial ceramic tubes. Firstly, they are eco-friendly components; Secondly, the service life is 3~5 times longer than that of metal pipes. Thirdly, the energy consumption of the high-temperature sintering process is 60% lower than that of metal smelting, Fourthly, corrosion resistance avoids chemical contamination. The above are typical virtues of industrial ceramic tubing.

The types of ceramic tubes in the industries can be classified as multi-dimensional:

- Raw material

- Oxide ceramic, including alumina (Al2O3), zirconia (ZrO2), quartz (SiO2)

- Non-oxide ceramic, including aluminum nitride (AlN), Silicon nitride (Si3N4), Silicon carbide (SiC), Boron nitride (BN)

- Shaping process

The regular shaping process for ceramic tubing covers dry pressing, hot pressing, extrusion, cold isostatic pressing (CIP), and ceramic molding injection.

- Sintering technology

Atmospheric pressure sintering is the most common sintering method; in order to improve the performance of the product, hot pressing sintering and microwave sintering are also used.

- Specific Uses

- Electrical & electronics: High-voltage ceramic insulator tube, fast-cooling aluminum nitride package tube

- High-temp industries: ceramic heater tube, thermocouple ceramic tube, molten metal delivery pipe

- Medical equipment: Ceramic co2 laser tube, zirconia surgical cannula, bioceramic implantation tube

- Chemical environmental protection: porous ceramic filter tube, acid-resistant zirconium composite tube

- New energy: fuel cell electrolyte tube, photovoltaic diffusion furnace tube

- By structural design

Ceramic tubes can be classified as single-layer, multi-layer, microporous tubes, and specially shaped tubes.

- By characteristics and properties

They can be classified as physical, mechanical, thermal, and electrical performance tubes.

- By industry standards

There are 4 typical industry standards, including

- General industrial grade: ASTM/ISO basic performance standards

- Food & medical grade: FDA/ISO 13485 biocompatibility requirements

- Semiconductor grade: SEMI standards (particle control < Class 10)

- Military-grade: MIL-STD extreme environment test

Ceramic tubes are a very hard industrial ceramic material, and professional tools and auxiliary facilities are required when cutting. The following is a list of items that need to be prepared before cutting:

※ Diamond saw blade or grinding wheel,

※ Cutting machine or angle grinding machine

※ Coolant (water or special coolant)

※ Protective equipment (goggles, masks)

※ Marking tools (marking pen)

※ Fixture & clamp

To ensure the quality of the cut ceramics, the cutting edge must be sharp as well as you must keep patient. You can conduct the processing step by step as follows:

- Preparation: Wear goggles and masks, and keep the work area clean

- Mark the cutting line: Use a marking tool to clearly mark the cutting line at the corresponding position

- Fixing ceramic tube: Using a fixture or clamp to fix the ceramic tube

- Saw blade installation: install the diamond saw blade or grinding wheel onto the cutting machine

- Start cutting: Align the saw blade with the cutting line to cut slowly, and keep steady without excessive force.

- Cooling: Use coolant to cool down while cutting to prevent overheating.

- Cleaning: Remove burrs or sharp edges, and use sandpaper to polish or carry out double-side lapping

Generally speaking, all ceramic tubes are high-temperature refractory ceramic components, the working temperature range of ceramic tubes is direct to the categories of technical ceramics, refer to the value for a few typical technical ceramic materials as follows.

- Aluminum oxide (Al2O3)

In the air: It can range from 1450℃ to 1800℃

In the vacuum state: It’s up to 2000℃

- Zirconium oxide (ZrO2)

The working temperature can reach up to 2200℃

- Silicon nitride (Si3N4)

The service temperature range is from 1000℃ to 1300℃.

- Silicon carbide (SiC)

The limit of using temperature can be from 1600℃ to 1700℃.

In conclusion, The operating temperature range of ceramic tubes depends on the type and purity of the material and is related to working conditions. When using ceramic tubes in high-temperature environments, special attention should be paid to the working temperature limit and thermal shock resistance.

In common cases, both 6906000000 and 6903000000 are recommended,also,the code can be confirmed after communicating with our sales.

- HSN code 6906000000: This code is used for customs classification and is applicable to products such as ceramic sleeves, conduits, grooved pipes, and pipe accessories.

- HSN code 6903000000: It states as other refractory ceramic goods, For Example, Crucibles, Muffles, Nozzles, Plugs, Supports, Cupels, Tubes, Pipe