Key Advantages

Ceramic thermostat housings supplied by Jinghui Ceramic have the following product highlights:

-Exceptional High-Temperature Resistance;

-Superior Thermal Stability & Low Expansion;

-High Electrical Insulation Strength;

-Excellent Corrosion & Wear Resistance;

-Long Lifespan & High Reliability.

Your Reliable Thermostat Ceramics Partner

Jinghui Ceramic is a manufacturer of thermostat ceramics with 10+ years of production experience. Our products are mainly based on 95% alumina and steatite (MgO.SiO2) ceramic materials. Our production processes include dry pressing, hot pressing, and isostatic pressing, as well as precision injection molding. Thermostat ceramic bases are primarily used in garages, thermostats, switches, relays, and other electrical appliances.

As we all know, thermostat ceramic parts are often customized to meet customer requirements, and the customization requirements vary across industries and applications. To meet these demands, we not only support a variety of special shapes but also optimize ceramic materials based on the product’s specific characteristics. To ensure product accuracy, our ceramic products sometimes undergo precision grinding or CNC machining after sintering, achieving dimensional accuracy.

We are committed to implementing our technology and creating value through our experience. Therefore, we are not just a supplier, but also a partner. We look forward to welcoming you.

Product By Features

Thermostat ceramic parts are mostly customized according to customer requirements, the features and shapes are different for customization. Considering the cost-effectiveness, most thermostat ceramic bases are used directly after sintering, and relatively few products undergo secondary processing.

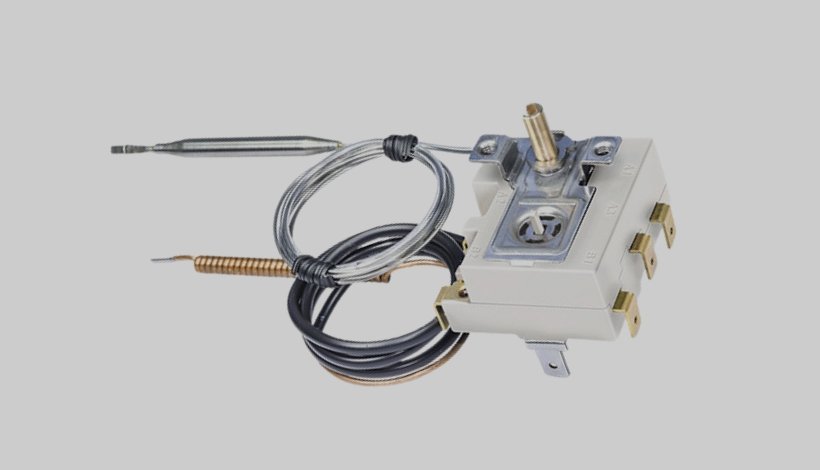

Ceramic thermostat Vs plastic thermostat

Ceramic thermostats are often used in scenarios with high requirements for temperature accuracy and stability; while plastic thermostats are suitable for devices with low durability requirements.

Ceramic thermostat:Extremely high, some ceramics can even withstand temperatures above 1600°C;

Plastic thermostat:Lower, such as PP material, the maximum temperature resistance is about 150℃.

Ceramic thermostat:Strong, not easily corroded by chemicals;

Plastic thermostat:Weak and easily corroded by chemicals.

Ceramic thermostat:Higher;

Plastic thermostat:Lower.

Ceramic thermostat:good;

Plastic thermostat:good.

Ceramic thermostat:More difficult to process and more expensive;

Plastic thermostat:Easy to process, various shapes.

Ceramic thermostat:Equipment that requires high precision and high stability, such as industrial equipment, home appliances, etc;

Plastic thermostat:Cost-sensitive common equipment such as remote controls, sockets, etc.

Temperature range and environment of ceramic thermostat

Thermostats ceramic are designed for extreme environments, with typical operating temperature ranges from hundreds to thousands of degrees Celsius, depending on the type of ceramic. They can operate stably in environments with high temperatures, chemical corrosion, or severe mechanical vibration, such as industrial furnaces, plastic machine heating systems, and automotive engine compartments where high reliability is required.

Jinghui Ceramics has nearly 10+ years of experience in the production of advanced ceramic products. Based on the characteristics of different fields, combined with different material properties and different technical requirements, we meet customers’ customization requirements and help customers’ career development with high-quality products and professional services.

The core advantage of ceramic thermostats lies in their excellent high temperature resistance and outstanding electrical insulation. Ceramic materials can remain stable at temperatures far above the melting point of metals, avoiding thermal deformation. At the same time, their inherent high insulation ensures safety in high-voltage environments, making them particularly suitable for harsh working conditions with high frequencies and high temperatures.

During installation, the primary concern is mechanical stress. Although ceramics are hard and wear-resistant, excessive compression or improper installation torque can cause brittle fracture. It is recommended to follow the torque values provided by the manufacturer and use appropriate mounting brackets. In addition, ensure that the connection terminals are clean and secure to prevent local overheating due to poor contact.