Superior Quality for You

- Ideal surface smoothness and flatness with minimal warpage

- High stiffness, bending, flexural strength, and wear resistance (even working under high-temp)

- Optimized thermal conductivity with faster heat dissipation

- High electrical insulation, dielectric strength and volume resistivity

- Perfect in adhesion with thick and thin film metallization paste

- Precise tolerance in dimensions and thickness, especially after lapping

- Chemical inertness to various oil and acid-base environments

Your Preferred Ceramic Substrate Supplier in China

We offer ceramic substrates in a variety of materials, including not only the most popular alumina (Al2O3) substrates, but also high-end aluminum nitride (AlN), silicon nitride (Si3N4) and zirconia (ZrO2) substrates.

Thanks to the ideal thermal management, electrical insulation, mechanical and chemical properties of ceramic substrates, they can significantly improve the performance and reliability of your electronic power modules and semiconductor packages, and also extend their service life.

We have in-house integrated capabilities in forming, laser cutting, laser scribing, polishing, machining and metallization. These capabilities enable us to produce a wide variety of standard or custom ceramic substrates. These include different sizes, thicknesses, shapes, surface treatments, and even unique properties required for specific applications.

| 1 | Available Materials | Al2O3 (96%, 99.6%), AlN, Si3N4, ZrO2, etc. |

| 2 | Standard Thickness | 0.25 mm, 0.3mm, 0.38 mm, 0.5mm, 0.635 mm, 0.76mm, 0.8 mm, 0.89mm, 1.0mm, etc. (customizable) |

| 3 | Standard Size | 120×120mm, 140×190mm, 130×140mm, 280×240mm, etc. (customizable) |

| 4 | Surface Roughness | Ra 0.05μm to 0.75μm (adjustable according to process requirements) |

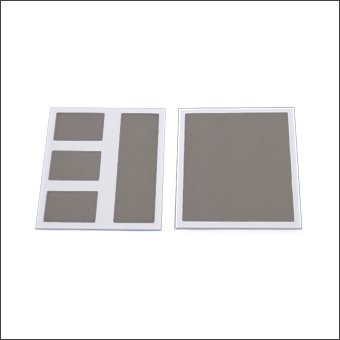

| 5 | Metallization | We can perform metallization on designated areas of ceramic substrates. |

Feel free to reach out to us to see what we can do for you.

By Material

Jinghui mainly supplies ceramic substrates in four types of ceramic materials: alumina (Al2O3), aluminum nitride (AlN), silicon nitride (Si3N4) and zirconia (ZrO2).

Excellent thermal conductivity is an outstanding feature of aluminum nitride substrate.

Core competitiveness lies in the perfect combination of high strength and toughness.

By Features

Our ceramic substrates can be processed into various shapes according to your requirements. And they can also be made in different colors to meet the needs of different applications.

The long strip ceramic substrates are often used in high-power LED, laser, and power modules.

Ceramic wafers are usually used in fields such as electronic components and semiconductor devices.

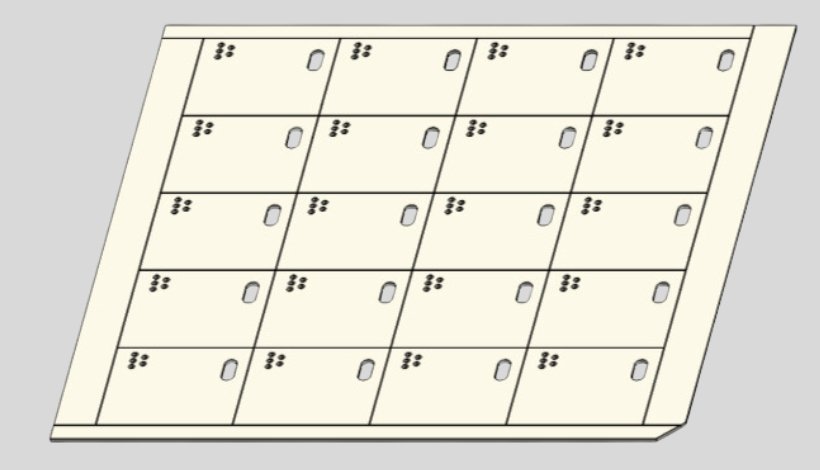

It’s a unique configuration in the ceramic substrate family, which can be shaped by dry pressing directly or laser cutting.

Various custom shapes can be obtained via laser cutting or machining to meet extensive specific uses.

To cater to the electrical circuits’ demands, some special pattern by laser cutting for the base substrate is needed.

The precision-machined ceramic substrates have more accurate dimensional tolerance, as well as more complex shapes.

Pink substrates are made from 94.4% alumina, which can improve optic performance and are readily identifiable.

Black ceramic substrates can be 92% alumina substrate, yttria stabilized substrate, or silicon nitride substrates.

Key Components in Power Modules

Ceramic substrates serve as critical carriers for high-performance electronic packaging. They fulfill multiple functions including mechanical support, environmental sealing, and thermal dissipation.

Currently, the most widely used ceramic substrate materials globally are A2O3, AlN, Si3N4, and ZrO2. Thanks to their unique properties, they play crucial roles in industrial electronics fields such as LEDs, automotive electronics, aerospace electronic components, and lasers.

Alumina substrates have dominated the power device field due to their mature technology and optimal cost-performance ratio.

- 96% Alumina Substrate: Commonly found in industrial control modules (such as automotive sensors), thick-film circuits, and heating elements.

- 99.6% Alumina Substrate: For high-frequency/microwave circuits, and high-precision thin-film circuits.

Aluminum nitride substrates are increasingly used in high-end power modules, radio frequency devices, and optoelectronics due to their higher thermal conductivity and equally excellent electrical insulation properties.

- Aluminum nitride substrates are commonly used in high-power power electronic devices such as high-power LED/LD chip carriers and IGBT/DBC power modules (electric vehicles/photovoltaics).

More About Our Ceramic Substrates

Our most mature product types are high-purity alumina (Al2O3) and aluminum nitride (AlN) ceramic substrates. We provide various specifications, shapes, and surface treatments. Additionally, we also offer metalized ceramic substrates.

Each of our substrates undergoes rigorous quality control to ensure consistency in dimensional accuracy and surface quality. We not only provide products but also offer expert advice on material selection and process adaptation based on our extensive experience.

- Material Properties

- Standard Specification

- Dimensional Accuracy

- Laser Processing

Below are the material properties of some of our most common ceramic substrates for your reference. Please feel free to contact us if you have any questions about any of these parameters.

1. Mechanical Properties

| Property | Unit | 96% Al2O3 | 99.6% Al2O3 | AlN |

| Color | / | White | Ivory | Gray |

| Density | g/cm3 | ≥3.70 | ≥3.95 | ≥3.33 |

| Light Reflectivity | % | 80%~90% | 85%~93% | 40%~60% (Visible light spectrum) |

| Flexural Strength | MPa | >350 | >500 | ≥380 |

| Fracture Toughness | MPa·m1/2 | 3.5~4.2 | 3.0~3.8 | 2.7~3.5 |

| Vickers Hardness | HV | 1500~1650 | 1600~1750 | 1200~1400 |

| Young’s Modulus | GPa | 300~350 | 370~400 | 310~350 |

| Camber | Length‰ | T≤0.3: ≤5‰, Others: ≤3‰ | ≤3‰ | ≤3‰ |

2. Thermal Properties

| Property | Unit | 96% Al2O3 | 99.6% Al2O3 | AlN |

| Max. Service Temperature (Non-loading) | ℃ | 1200 | 1400 | >1000 |

| CTE (Coefficient of

Thermal Expansion) @ 20-400℃ |

1×10-6/℃ | 7.0~7.5 | 6.5~7.2 | 4.2~4.8 |

| Thermal Conductivity @ 20℃ | W/(m·k) | 20~25 | 28~35 | 170-230 |

3. Electrical Properties

| Property | Unit | 96% Al2O3 | 99.6% Al2O3 | AlN |

| Dielectric Constant | / | 9.0~9.5 | 9.5~10.0 | 8.6~9.0 |

| Volume Resistivity | Ω·cm | >1014 | >1015 | >1014~>1015 |

| Dielectric Strength | KV/mm | 10~15 | 15~25 | 15~25 |

The following are our standard specifications. We also support customization.

1. Alumina Substrate

| 99.6% Al2O3 Substrate | |||||||

| Thickness (mm) | Maximum Size (mm) | Shape | Forming Method | ||||

| As Fired | Lapped | Polished | Rectangular | Square | Round | ||

| 0.1-0.2 | 50.8 | 50.8 | ✓ | ✓ | Tape Casting | ||

| 0.25 | 114.3 | 114.3 | ✓ | Tape Casting | |||

| 0.38 | 120 | 114.3 | 114.3 | ✓ | Tape Casting | ||

| 0.5 | 120 | 114.3 | 114.3 | ✓ | Tape Casting | ||

| 0.635 | 120 | 114.3 | 114.3 | ✓ | Tape Casting | ||

|

Other special thicknesses within the thickness range of 0.1-0.635mm can be achieved by lapping. |

|||||||

| 96% Al2O3 Substrate | |||||||

| Thickness (mm) | Maximum Size (mm) | Shape | Forming Method | ||||

| As Fired | Lapped | Polished | Rectangular | Square | Round | ||

| 0.25 | 120 | 114.3 | 114.3 | ✓ | Tape Casting | ||

| 0.3 | 120 | 114.3 | 114.3 | ✓ | Tape Casting | ||

| 0.38 | 140×190 | ✓ | Tape Casting | ||||

| 0.5 | 140×190 | ✓ | Tape Casting | ||||

| 0.635 | 140×190 | ✓ | Tape Casting | ||||

| 0.76 | 130×140 | ✓ | Tape Casting | ||||

| 0.8 | 130×140 | ✓ | Tape Casting | ||||

| 0.89 | 130×140 | ✓ | Tape Casting | ||||

| 1 | 280×240 | ✓ | Tape Casting | ||||

| 1.5 | 165×210 | ✓ | Tape Casting | ||||

| 2 | 500×500 | ✓ | Tape Casting | ||||

|

Other special thicknesses within the thickness range of 0.1-2.0mm can be achieved by lapping. |

|||||||

2. Aluminum Nitride Substrate

| AlN Substrate | |||||||

| Thickness

(mm) |

Maximum Size (mm) | Shape | Forming Method | ||||

| As-fired | Lapped | Polished | Rectangular | Square | Round | ||

| 0.1-0.2 | 50.8 | 50.8 | ✓ | ✓ | Tape Casting | ||

| ≥0.2 | 114.3 | 114.3 | ✓ | ✓ | Tape Casting | ||

| 0.38 | 140×190 | 140×190 | 120 | ✓ | ✓ | Tape Casting | |

| 0.5 | 140×190 | 140×190 | 120 | ✓ | ✓ | Tape Casting | |

| 0.635 | 140×190 | 200 | 200 | ✓ | ✓ | ✓ | Tape Casting |

| 1 | 140×190 | 300 | 200 | ✓ | ✓ | ✓ | Tape Casting |

| 1.5 | 300 | 200 | ✓ | ✓ | Tape Casting | ||

| 2 | 300 | 200 | ✓ | ✓ | Tape Casting | ||

| 2.5 | 300 | ✓ | ✓ | Tape Casting | |||

| 3 | 300 | ✓ | ✓ | Tape Casting | |||

| … | 450 | ✓ | ✓ | Isostatic Pressing | |||

| 10 | 450 | ✓ | ✓ | Isostatic Pressing | |||

|

Other special thicknesses within the thickness range of 0.1-3.0mm can be achieved by lapping. |

|||||||

1. Dimensional Tolerances

| Alumina Substrate | ||||

| Item | Substrate Thickness (mm) | Standard Tolerance (mm) | Best Tolerance (mm) | Laser Cutting Tolerance (mm) |

| Length and Width Tolerance | / | ±2 | ±0.15 | |

| Thickness Tolerance | T<0.3 | ±0.03 | ±0.01 | |

| 0.30-1.0 | ±0.05 | ±0.01 | ||

| T>1.0 | ±10% | ±0.01 | ||

| Aluminum Nitride Substrate | ||||

| Item | Substrate Thickness (mm) | Standard Tolerance (mm) | Best Tolerance (mm) | Laser Cutting Tolerance (mm) |

| Length and Width Tolerance | / | ±2 | ±0.15 | |

| Thickness Tolerance | T<1.0 | ±0.03 | ±0.01 | |

| 1.0≤T<1.5 | ±0.05 | ±0.01 | ||

| T≥1.5 | ±0.07 | ±0.01 | ||

2. Surface Roughness

| Alumina Substrate | |||

| Material | Surface Roughness (μm) | ||

| As Fired | Lapped | Polished | |

| 96% Al2O3 | Ra 0.2-0.75 | Ra 0.3-0.7 | Ra ≤0.05 |

| 99.6% Al2O3 | Ra 0.05-0.15 | Ra 0.1-0.5 | Ra ≤0.05 |

| Aluminum Nitride Substrate | |||

| Material | Surface Roughness (μm) | ||

| As Fired | Lapped | Polished | |

| AlN | Ra 0.4 | Ra 0.3-0.7 | Ra ≤0.05 |

1. Hole Size

| Alumina Substrate | |

| Hole Diameter (mm) | Standard Tolerance (mm) |

| φ≤0.5 | 0.08 |

| φ>0.5 | 0.2 |

| Aluminum Nitride Substrate | |

| Hole Diameter (mm) | Standard Tolerance (mm) |

| φ≤0.5 | 0.08 |

| φ>0.5 | 0.2 |

2. Laser Scribing

| Alumina Substrate | |

| Substrate Thickness (mm) | Laser Scribing Depth / Substrate Thickness (%) |

| 0.2-0.3 | 40%±5% |

| 0.3<T≤0.5 | 50%±3% |

| 0.5<T≤1.0 | 43%±3% |

| 1.2 | 55%±3% |

| 1.5 | 55%±3% |

| 2.0 | 55%+10% |

| The scribing spot can be in different sizes. Generally there are small spot 0.03-0.04mm (Substrate Thickness≤0.5mm ) and large spot 0.08-0.1mm (Substrate Thickness>0.5mm), and the accuracy is ±0.01mm. | |

| Aluminum Nitride Substrate | |

| Substrate Thickness (mm) | Laser Scribing Depth / Substrate Thickness (%) |

| 0.2-0.3 | 40%±5% |

| 0.5<T≤1.0 | 50%±3% |

| 1.0<T≤1.2 | 55%±3% |

| 1.2<T≤1.5 | 60%±3% |

| 2.0 | 45% (Extreme Depth) |

| The scribing spot can be in different sizes. Generally there are small spot 0.03-0.04mm (Substrate Thickness≤0.5mm ) and large spot 0.08-0.1mm (Substrate Thickness>0.5mm), and the accuracy is ±0.01mm. | |

We believe your primary consideration should be heat dissipation. If heat is an urgent issue for you (such as power devices or lasers), you must choose aluminum nitride (AlN). If you don’t have high requirements for heat dissipation and are more concerned with insulation, strength, and cost, then you can choose alumina (Al2O3).

In terms of ceramic substrates, the main difference between 96% alumina and 99.6% alumina lies in their properties.

99.6% alumina offers better thermal conductivity, dielectric strength, high-temperature stability, and surface finish compared to 96% alumina. If your application involves high frequency, high voltage, high temperature, or precision thin-film processes, we recommend that you choose 99.6% alumina.

However, if you are using alumina substrates in ordinary circuits, 96% alumina is sufficient. Additionally, it is more economical.

Our best surface roughness (Ra) is below 0.05μm. And our standard surface roughness is typically ≤0.75 μm.

Surface roughness does indeed affect metallization. Generally, the smoother the surface, the better the adhesion of subsequent coatings and the higher the circuit precision. This is especially important for thin-film circuits and fine-linewidth processes.

We can do precision machining on ceramic substrates. Please provide your drawing. We will evaluate the feasibility of production and inform you of the precision we can achieve.

We can provide free samples for standard specifications.

Our customization services include different sizes, special thicknesses, irregular shapes, different surface roughness levels, and metallization treatment for ceramic substrate surfaces. Please tell us your needs, and we will evaluate and provide a quote.

Standard products have a lower MOQ, while the MOQ for custom products depends on the complexity of the manufacturing process.

Delivery time will be assessed based on the order. The standard delivery time is generally 2-4 weeks. For urgent orders or samples, we will prioritize processing and ship them as quickly as possible.