Features and Benefits

- Ideal flatness and low roughness (<1.5μm)

- Excellent thermal shock resistance up to 1000℃

- High-temp stability if even extreme heat conditions

- Chemical durability in various acids-base environments

- Custom shape availability fit for firing bespoke parts

- Energy-saving and precised ceramics after sintering

Chinese Expert Ceramic Plate Setters Manufacturer

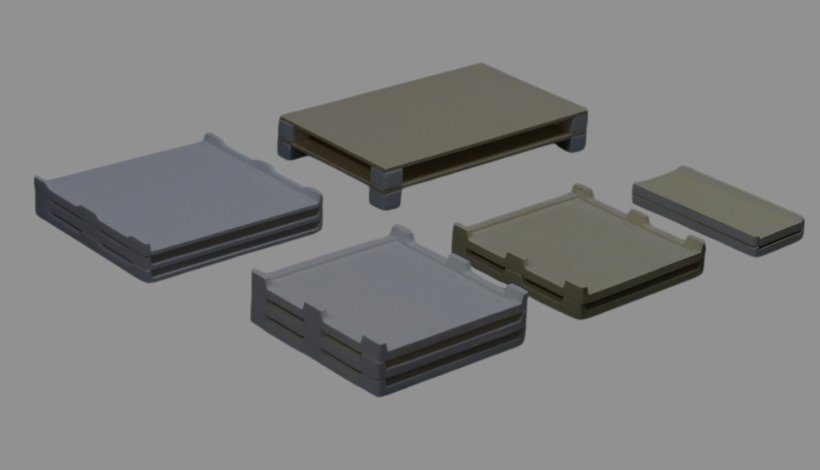

Advanced ceramic plate setters play a crucial role in firing molded parts. They can make your components more precise in terms of dimensions and shapes, and reduce energy consumption. In comparison with traditional graphite and tungsten setters, advanced ceramic setters can significantly promote your parts’ quality and also generate more competition.

Our facility manufactures a wide range of ceramic plate setters, the material covers high-purity alumina, aluminum nitride, boron nitride, zirconia ceramic, corundum mullite, and so on. They can be formed by dry pressing, cold isostatic pressing, tape casting, hot pressing with custom geometries, and the maximum size is 500mm. Precision flat grinding for ceramic setters needs to be conducted to minimize the deformation and get desirable sizes after sintering. All of them offer versatility and are ideal for sintering ceramic injection molding (CIM), metal injection molding (MIM), low temperature co-fired ceramics (LTCC), and so on.

Our philosophy is to grow with our customers and always be behind them. If you are searching for a reliable ceramic plate setter partner or a cost-down solution, don’t hesitate to call or email us today.

By Materials

According to the material, there are several typical products for your reference.

High-temperature stability (1,600°C) and electrical insulation for kiln furniture and furnace components.

Ultra-high thermal conductivity (170–200 W/mK) for semiconductor wafer annealing and LED packaging.

Non-stick surface and chemical inertness,and mainly used for molten metal handling and CVD processes.

High fracture toughness (6–8 MPa√m) for precision sintering of dental and aerospace components.

Products by Features

Our cceramic plate setters are custom made to order and come in a variety of shapes and sizes.

Uniform heat distribution for ceramic/powder metallurgy sintering in rotary kilns.

Secure holding of cylindrical workpieces in high-temperature brazing and glass molding.

Corrosion-resistant support for wire mesh catalysts in chemical reactors.

Multi-layer stacking for batch processing of electronic ceramics and battery materials.

A Quick Guide for Ceramic Plate Setters

Advanced Ceramic plate setters are high-end sintering support tools designed based on high-performance ceramic materials. Through material innovation, structural optimization and functional integration, they are mainly used in precision manufacturing processes such as metal injection molding (MIM), low-temperature co-fired ceramics (LTCC), and multilayer ceramic capacitors (MLCC). Compared with traditional setters, they significantly improve the stability, precision and efficiency of the high-temperature sintering process, and are particularly suitable for the production of high-value-added and high-complexity products.

Technical Properties of ceramic setters’ materials

| Property | Alumina

(Al2O3) |

Zirconia (ZrO2) | Aluminum nitride (AlN) | Silicon Nitride

(Si3N4) |

Boron Nitride

(h-BN) |

|

| Max. Use temperature(℃) | Air | 1600~ 1700 | 1500~ 1600 | 1000~1300 | 1200 ~1400 | 800~1000 |

| Inert or

vacuum |

1800~1900 | 2200~2400 | 1800~2000 | 1600~1700 | 1800~2400 | |

| Thermal Conductivity (W/m.K) | 20~30 | 2~3 | 170~230 | 30~40 | 30~60 | |

| Thermal Expansivity

(* 10-6/ ℃) |

7~8 | 10~11 | 4.5 | 3.2 | 1~3 | |

| Bending Strength

(MPa) |

350~450 | 900~1000 | 350 | >1000 | ||

| Hardness

(HV/GPa) |

15~20 | 12~14 | 9~9.5 | 24~30 | 0.3~1 | |

| Thermal Shock Resistance | Good | Better | Good | Best | Best | |

| Chemical Stability | Resistant to acid and alkali, and corrosion-resistant | High inertness and resistant to molten metals | Corrosion Resistance | Resistant to acid and alkali, oxidation resistance | Resistant to molten metals and acids-base | |

Typical applications

- Firing setters for electronic component materials

- Setters for heat treatment of metal injection products

- kiln plate setters for furnace for support and hold use

- Jigs for brazing process

The traditional plate setters are metal (i.e: stainless steel and other heat-resisting alloy) and graphite, refer to the The advantages of advanced ceramic setters compared to them can present from following aspects.

- Better high temperature resistance: The Silicon nitride or silicon carbide setter can withstand 1600℃, but metal setters start to soften at 1200℃.

- Lower thermal expansivity: The silicon nitride, silicon carbide, Boron nitride setters have much lower than stainless steel one, so they can withstand rapid temperature rises and drops without cracking.

- Optimized mechanical strength: As the hardness of advanced ceramics is similar to diamond, so the wear resistance and mechanical strength of ceramic setters are much higher than traditional ones.

- Exceptional chemical stability: They can resist corrosion, oxidizing without pollution risk because of high purity of raw material.

- Cost advantage: Since advanced ceramic setters are recyclable, also the service life is much longer than traditional ones with less maintenance times, so the overall cost is lower accordingly.

- Idea for extreme working conditions: They are fit for high-vacuum, inert gas & reducing atmospheres, high-voltage and high-current fields.

- Other advantages: More lighter weight, better surface quality and easier to separate ceramic parts after sintering than metal setters.

Generally speaking, advanced ceramic setters have ideal chemical stability, also they can withstand corrosion and molten materials. Please find the following tables in different operation conditions.

| Raw Material | Acid-resistant gas | Alkali-resistant gas | Resistant to Molten metals | Resistant to molten salt/glass |

| Aluminum Oxide

(Al2O3) |

Average – High (<1200℃) |

Average | Average

(Non-active metals) |

Low |

| Aluminum Nitride

(AlN) |

High

(Dry gas) |

Average | High (Except for Al, Ca) |

Low |

| Silicon Nitride

(Si3N4) |

High | High

(<1000℃) |

High (nonferrous) |

Average |

| Boron Nitride

(BN) |

Higher

(In the inert) |

Average | Higher

(inoxidizability) |

Low |

| Zirconium Oxide

(ZrO2) |

High

(Except for HF) |

High

(<800℃) |

High (Except for Al, Cu) |

High |

In most common cases, alumina setters, silicon nitride setters, boron nitride setters and zirconia ceramic setters are used in the firing process for CIM parts. When selecting the type, you need to comprehensively consider from four aspects: material properties, part characteristics, process conditions and cost.

Choosing a right ceramic plate setter for MIM parts, it’s direct to the quality of shapes and dimensional consistency of MIM parts. You can find the reference ceramic setters for as follows:

- Alumina setters: Low cost, good corrosion resistance and easy to process, It’s suitable for Low-load, non-high-precision parts.

- Silicon carbide setters: High strength, high thermal conductivity and excellent thermal shock resistance, however, they are very expensive. They are suitable for high-precision and high-temperature sintered parts.

- Zirconia ceramic setters: Ultra-high strength, high temperature resistance and low thermal conductivity, but it’s hard to machine with high cost. Therefore, they are fit for high value added MIM parts.

- Silicon nitride setters: extreme high mechanical strength and high thermal shock resistance so that the cost is much higher than others. They are suitable for extreme temperature fluctuations or high-mechanical loading scenarios.

Due to the unique process requirements of low-temperature co-fired ceramics, such as low-temperature sintering, multi-layer structure, and high-precision alignment, special attention should be paid to the thermal matching, surface quality, and structural design of the ceramic setter plate.

The materials commonly used for setter plates for low-temperature co-fired ceramic parts include alumina, cordierite ceramics, mullite ceramics, and aluminum nitride ceramics. The following is a comparison of several materials in terms of performance, cost, application scenarios, etc.

- Alumina setters: easy to machine, adjustable thermal expansivity, low cost.They are fit for general-purpose LTCC, especially non-high-precision multi-layer substrates.

- Cordierite ceramic setter: Excellent thermal shock resistance and low CTE with average cost. They are fit for precision LTCC components with high CTE matching requirements.

- Mullite ceramic setters: resist to oxidization in high temperature and average CTE with middle level cost. They are fit for applications requiring antioxidant and CTE matching.

- Aluminum nitride setters: high thermal conductivity and adjustable CTE but much high cost, they are fit for High-frequency/high-power LTCC devices.