Product Overview

Precision ceramic structural components designed specifically for harsh industrial environments address the pain points of metal or plastic parts in automated equipment, such as easy wear, corrosion, and short lifespan.

***Industrial Automation field such as precision bearings, mechanical guides, textile thread guides, measurement probes etc;

***Structural ceramics with mechanical properties: high wear resistance, dimensional stability, low friction coefficient;

***Some thermal and chemical functions;

***Requiring secondary processing after sintering;

***A certain dimensional accuracy and surface quality.

Your Reliable Special Engineering Ceramics Partner

Jinghui Ceramic is a manufacturer of advanced ceramics with 10+ years of production experience. Our products are based on alumina and zirconia ceramic materials, and we also supply special engineering ceramic parts made of aluminum nitride and silicon nitride. Our production processes include dry pressing, hot pressing, and isostatic pressing, as well as precision injection molding. Combined with precision sintering at temperatures exceeding 1600°C, we ensure product density exceeding 99%, minimizing dimensional deviation and cracking.

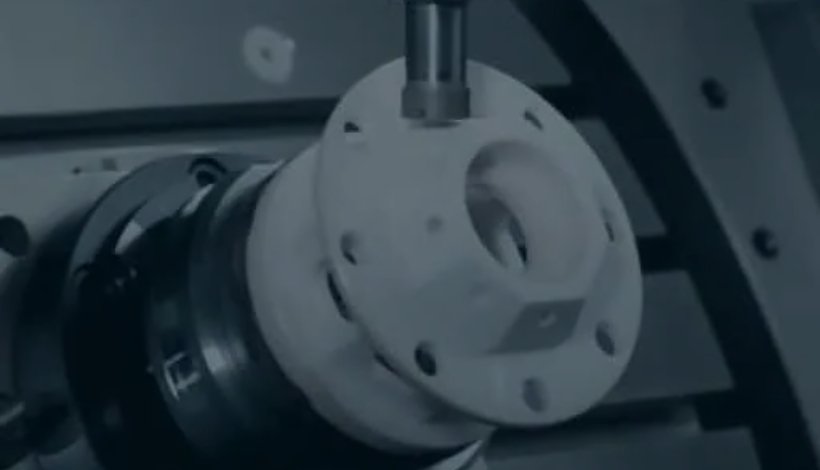

Customization is one of our core competencies. We can design and manufacture custom parts based on your drawings or technical requirements, covering material selection, dimensions, tolerances, and surface treatment. Whether it’s complex irregular shapes or assemblies requiring special properties, our engineering team can provide solutions for you. To ensure product accuracy, our engineering ceramic products undergo precision grinding or CNC machining after sintering, achieving dimensional accuracy of up to 0.001 mm.

To date, we have served over 500 customers in sectors including medical, green energy, and semiconductors. We are committed to implementing our technology and creating value through our experience. Therefore, we are not just a supplier, but also a partner. We look forward to welcoming you.

Product By Features

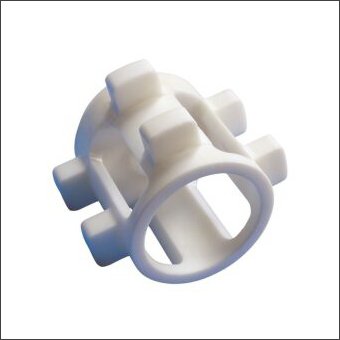

Engineering ceramic parts are mostly customized according to customer requirements, the features and shapes are different for customization, generally, the structure is more complex and requires more machining processes.

Zirconia ceramic impeller, for mechanical rotation.

99.7% alumina, slot and hole for structural assembly.

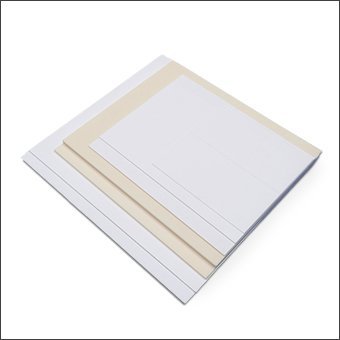

Yttria Stabilized zirconia,multi-hole structural cover plate.

99.7% Alumina, customized functional structural components.

Engineering Structural Ceramic Parts Feature

Engineering structural ceramics were created to meet the material needs of rapidly developing technologies such as industrial automation, intelligent machinery, aerospace, aviation, and atomic energy, giving full play to the mechanical properties of ceramics that are different from those of metals and plastics.

Application of wear-resistant materials, abrasives, etc.

Gas turbine components, refractory and corrosion-resistant materials, cutting tools, etc.

Application of device ceramics, circuit substrates, mold materials, and cutting tools.

Refractory materials in metallurgical metals, high-temperature anion conductors, sensors, cutting tools and other application environments.

Mainly use three materials: alumina, zirconium oxide and aluminum nitride.

The product cannot be used directly after sintering and requires secondary machining, such as cutting, punching, grinding, lapping and polishing, to achieve the required shape and dimensional accuracy.

Quality and Reliability of Engineering Ceramic Parts

The manufacturing of engineering ceramic products differs somewhat from that of other ceramic parts. Due to their complex structures, injection molding is typically used, but tape casting and dry pressing can also be used to create simple structures, followed by secondary machining to create more complex structures. Due to the inherent rigidity and brittleness of ceramics, high-temperature sintered ceramic products are often processed using surface grinding, cylindrical grinding, centerless grinding, CNC precision machining, and laser machining to improve product precision and facilitate the manufacture of complex shapes and tight tolerances.

Quality control objectives for engineering ceramic parts

Customer Satisfaction >95%

On Time Delivery >96%

QPPM <7000 PPM

Properties of commonly used ceramic materials

The properties of three common materials for engineering ceramics are described in the following table:

| Material | 99% Alumina | Zirconia (YSZ) | AlN (99% Purity) |

| Density (g/cm³) | >3.8 | 6.0 | 3.3 |

| Flexural Strength (MPa) | >310 | 800 | >310 |

| Modulus of Elasticity (GPa) | 350 | 200 | 310 |

| Vickers Hardness (HV) | >1520 | 1230 | 1040 |

| Thermal Conductivity (W/m·K) | 29 | 3 | 170–230 |

| Max. service temperature (℃) | 1600 | 1500 | 1200 |

Jinghui Ceramics has nearly 17 years of experience in the production of engineering ceramic products. Based on the characteristics of different fields, combined with different material properties and different technical requirements, we meet customers’ customization requirements and help customers’ career development with high-quality products and professional services.

Ceramic parts generally outperform metals and engineering plastics in terms of wear resistance, corrosion resistance, rigidity, and high-temperature stability. In high-speed, high-load environments or those containing corrosive media, ceramic parts can significantly reduce wear rates, extend equipment maintenance cycles, and minimize downtime due to parts replacement, thereby improving overall equipment efficiency and long-term operational economy.

Alumina ceramics offer excellent overall performance and cost-effectiveness, making them suitable for most wear-resistant, insulating, and general corrosive environments. Zirconia ceramics, on the other hand, are renowned for their high fracture toughness and superior wear resistance, with a mechanical strength approximately twice that of alumina. They are better suited for critical components subjected to impact loads, stress concentrations, or where extremely high reliability is required. The choice between these ceramics and alumina ceramics requires comprehensive consideration of specific operating conditions, performance requirements, and budget.

While engineering structural ceramics emphasize their physical and mechanical properties, functional ceramics prioritize non-mechanical properties. These materials typically possess one or more functions, such as electrical, magnetic, optical, thermal, chemical, and biological. Some ceramic materials, such as zirconium oxide, aluminum oxide, and silicon nitride, are both structural and functional.