Overview

The main purpose of ceramic surface metallization in industrial ceramics is electronic components in specific scenarios, or for ceramic-metal sealing, or for related electromagnetic shielding effects.

Ceramic-Metal Sealing Process Data

| Process Type | Liquid phase process | Gas phase process | Solid phase process |

| Characteristics | During metallization, there is a certain liquid phase between the ceramic and metal interfaces. | Metal vapor or ions are heated, evaporated or sputtered onto the ceramic surface. | Under high pressure, high temperature or electrostatic attraction, the ceramic and metal surfaces are in close contact. |

| Features | Widely used, film process,Including molybdenum-manganese method, active alloy method, and oxide solder method. | Thin film technology | Including pressure sealing, solid diffusion sealing, electrostatic sealing, etc. |

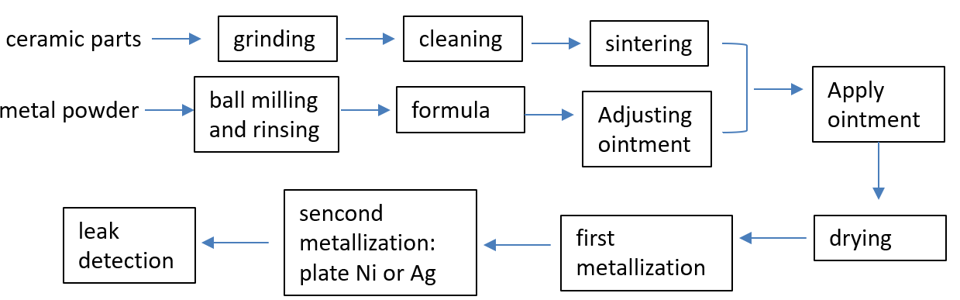

As described in the table above,there are many methods for metallization of ceramic surfaces. Our most commonly used method is the molybdenum-manganese method. Special Mo-Mn metal slurry is applied to the ceramic surface by screen printing or manual paste application, and then dried on an automatic baking line and sintered at high temperature to form a metallization layer.

Molybdenum-manganese process

Production Equipment

Generally, after coating molybdenum and manganese, many customers also need to plate Ni or Ag according to their needs. For example, metallized ceramic tubes with 95% alumina will be metallized at both ends, Mo-Mn 15~40 um,then Ni 3~6 um.

-

manual screen printing metallization

manual screen printing metallization -

automatic screen printing workshop

automatic screen printing workshop -

hydrogenation furnace workshop

hydrogenation furnace workshop -

metallizing & brazing workshop

metallizing & brazing workshop -

metallization scribing workshop

metallization scribing workshop -

metallizing parts detection

metallizing parts detection

Advanced Ceramic Metallization

Ceramic metallization involves bonding a metal layer (e.g., Mo, Cu, Ag) to advanced ceramics (Al₂O₃, AlN, SiC) to enable electrical conductivity, thermal management, or structural integration. Key methods include magnetron sputtering, Mo-Mn sintering, and active metal brazing.

Key Techniques & Advantages

-

Magnetron Sputtering:

-

Process: Uses argon plasma to bombard a metal target (e.g., Zr), depositing a uniform layer (50–200 nm) under vacuum (4.5–5.5×10⁻¹ Pa).

-

Benefits: High precision (±0.01 mm), minimal thermal damage, and compatibility with complex ceramic part surfaces.

-

-

Active Metal Brazing:

-

Materials: Ti-, Zr-, or Hf-based alloys react with ceramics to form interfacial compounds (e.g., Ti₃AlC₂), achieving shear strength >50 MPa.

-

Applications: Aerospace engine components and semiconductor packaging.

-

-

Direct Bonded Copper (DBC):

-

Mechanism: Bonds Cu foil to Al₂O₃/AlN via eutectic Cu-O phases at 1,065–1,083°C, enabling thermal conductivity up to 200 W/mK.

-

-

Mo-Mn Method:

-

Steps: Apply Mo-Mn paste, sinter at 1,400–1,600°C to form a glass-phase bond. Modified with oxides (Y₂O₃, ZrO₂) to reduce sintering temps to 1,300°C.

-

Metallization enables ceramics to conduct electricity, essential for substrates and sensors. For instance, AlN ceramics with magnetron-sputtered Ag layers achieve resistivity <10⁻⁴ Ω·cm, supporting 5G RF devices. The process also enhances thermal dissipation, reducing junction temperatures by 30% in high-power modules.

The Mo-Mn method forms a glass-phase layer during sintering, which chemically bonds to both ceramic and metal. Adding Y₂O₃ reduces sintering temperatures to 1,300°C, minimizing thermal stress. This increases bond strength by 60% compared to traditional methods, ideal for vacuum tubes and microwave components.

Low conductivity (e.g., ZrO₂: 2–3 W/mK) causes heat buildup during sintering, leading to cracks. Solutions include gradient heating (5°C/min) and using nano-sized metal powders to enhance interfacial contact. Laser-assisted sintering further reduces thermal stress, achieving defect-free coatings.

Yes. For example, SiC components with TiN coatings resist HCl (pH <1) and NaOH (pH >12) corrosion. Post-coating passivation (e.g., anodizing) improves durability, extending service life in chemical pumps by 5x.