Overview

Ceramic forming is the process of using various methods to make blanks (greenware) with a certain shape and size from prepared ceramic raw materials.Common ceramic forming methods are described in the table below. The ceramic body after forming is only a semi-finished product, and it still needs to go through multiple processes such as drying, glazing, loading, firing, and machining.

| Common methods of ceramic forming | ||||

| Ceramic Forming | Blank State | Forming Type | Moisture Content of Blank | Mold Materials |

| Stamping process | powder | Dry pressing | 6%~8% | Steel mold |

| Hot die casting | paraffin 12.5%~13.5% | Steel mold | ||

| Isostatic pressing | 1.5%~3% | Rubber mold | ||

| Plastic forming | plastic clay | Extrusion forming | 18%~26% | Steel mold |

| Injection molding | 18%~26% | Steel mold | ||

| Rolling film forming | 18%~26% | no mold | ||

| Slurry forming | slurry | Slip casting | 30%~40% | Hot method: steel mold, cold method: plaster mold |

| Gel-casting | 30%~40% | |||

| Tape casting | 30%~40% | scraper | ||

Production Equipment

We have multiple ceramic forming technologies: Hot die casting can prepare engineering ceramic parts of various complex shapes; Dry pressing is suitable for mass production of simple shapes; Isostatic pressing can achieve complex structures and uniform density; Tape casting is suitable for manufacturing various ultra-thin industrial ceramic plates, ceramic substrates, etc.; Extrusion forming can produce ceramic tubes, ceramic rods and ceramic burner plates; Injection molding is suitable for producing micro-shaped special parts.

-

Ceramic Injection Molding

Ceramic Injection Molding -

Ceramic Dry Pressing

Ceramic Dry Pressing -

Ceramic Hot die casting

Ceramic Hot die casting -

Ceramic Isostatic Pressing

Ceramic Isostatic Pressing -

Ceramic Extrusion

Ceramic Extrusion -

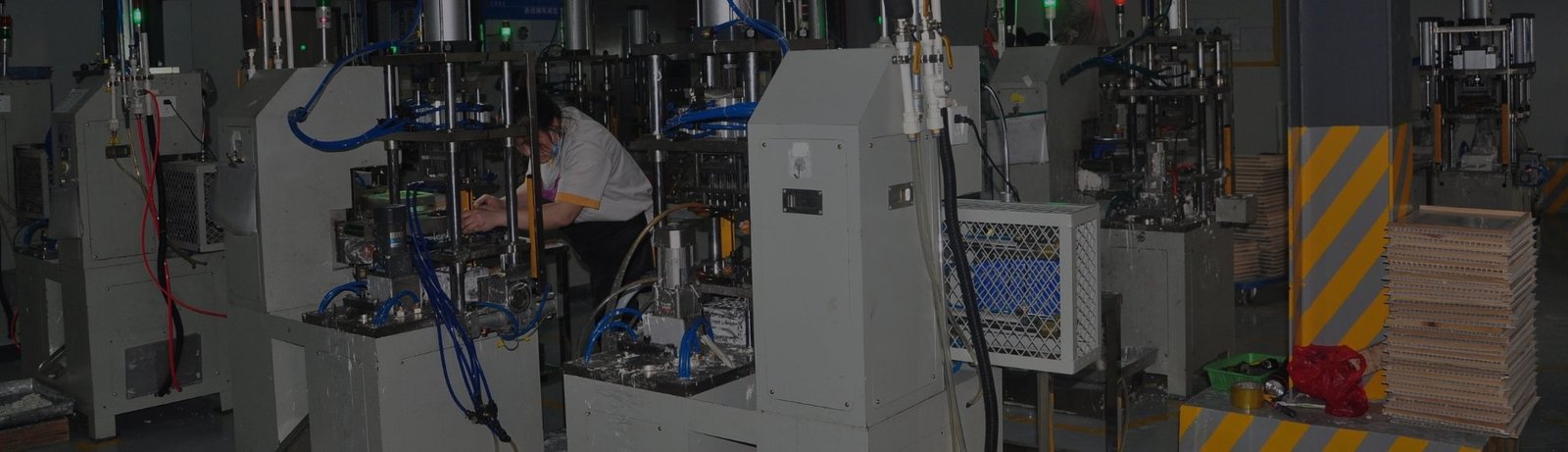

Hot Pressing Workshop

Hot Pressing Workshop

Selection of ceramic forming methods

There are many ceramic forming methods, and it is very important for us to choose the forming method that is suitable for production. We usually determine the corresponding process route based on the product drawings or samples, select the appropriate forming method, make process preparations and put the ingredients into production.

1. The shape, size and thickness of the product

Products with complex or large shapes, low dimensional accuracy requirements, thin tires, and thick walls can be formed by grouting. Products with regular geometric shapes can be formed by pressing. Products with simple rotating bodies can be formed by spinning in the plastic molding method.

2. Performance of blank

Blanks with good plasticity are suitable for plastic molding, while blanks with poor plasticity can be molded by grouting or dry pressing.

3. Product output and quality requirements

Products with high output can use plastic molding, products with low output can use slip casting, and products with high quality requirements can use isostatic pressing.

The following table statistics some of our experience in selecting molding methods in actual production, which can be used for reference.

| Ceramic Forming | Shape | Size | Uniformity | Efficiency | Cost |

| Dry pressing | flat shape | a bit bad | high | a bit low | |

| Cold isostatic pressing | tube, cylinder, sphere | large size | good | middle | middle |

| Hot die casting | complex shape | small size | a bit good | high | Low |

| Tape casting | substrate | thickness<1mm | good | high | middle |

| Extrusion forming | cylindrical | long size | middle | high | a bit low |

| Injection molding | complex shape | large size | good | high | middle |

| Slip casting | complex shape | small size | a bit good | a bit low | low |

In general, under the premise of ensuring product output and quality, the molding method with feasible process, simple equipment, convenient operation, shortest production cycle and best economic benefits is selected.

In addition to the common molding methods, new advanced molding methods include: filter press casting, direct coagulation casting (DCC), electrophoretic deposition (EPD), centrifugal deposition casting (CDC), and solid freeform fabrication (SFF).

Dry pressing is a process in which powdered blanks are pressed into a mold under high pressure. In essence, the particles are brought close to each other in the mold under the action of external force, and the internal friction firmly connects the particles and maintains a certain shape. There are several steps in dry pressing: feeding, pressurizing and forming in the mold, demoulding, removing the blank, and cleaning the mold.

Utilizing the fluidity of melted paraffin wax, a non-plastic ceramic powder is uniformly mixed with hot wax to form a slurry. This slurry is then injected into a metal mold under a certain pressure for molding. After cooling and solidification, the molded green body is removed. After the green body has its sprue removed and properly repaired, it is buried in an adsorbent and heated for degreasing, removing the paraffin wax and other volatile additives, and then sintered into a ceramic part.