Key Features

Jinghui’s ceramic eyelets are specifically designed for cable routing and abrasion protection in textiles, electronics, and medical equipment., and have some relatively common technical specifications as follows:

Professional Ceramic Eyelets Manufacturer

Made of advanced materials such as alumina (Al₂O₃) and zirconia (ZrO₂), ceramic eyelets have excellent wear resistance, corrosion resistance and low friction. They are precision parts designed for textile machinery and have excellent durability and performance in high-speed line guidance.

We can customize the internal hole structure to accommodate various shapes, including round, elliptical, and polygonal designs, and support wire diameters from 0.1 to 10 mm. For our ceramic eyelets, we also consider design features to minimize friction during wire insertion, such as polished inner wall surfaces and chamfered edges, thus reducing the rate of fiber breakage.

We have a variety of stock sizes for you to choose from, and we can also customize them for you if necessary. Welcome to inquire.

By Features

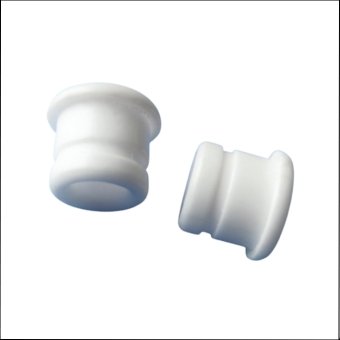

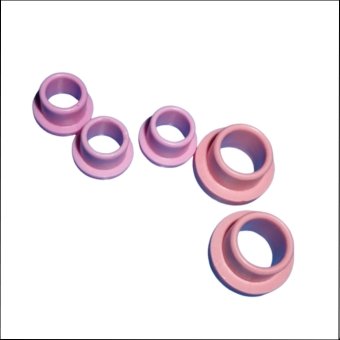

Ceramic eyelets are the one of the main product type of texitile ceramics, and main materials of ceramic eyelets are 95% alumina, 99% alumina, zirconia and titania ceramic.

Colors can be customized according to customer requirements.

The number of grooves may be one or several to add additional sealing.

The threads on the surface serve a functional purpose.

Zirconia are used more frequently in applications with higher wire density.

The threaded design on the outer column is commonly used for easy assembly.

The larger inner diameter is designed for guiding thicker wires.

wear-resistant and lower friction ,be suitable for use in fine weaving and knitting machines.

The glazed ceramic surface is smoother, which greatly reduces friction.

Technical Specifications

Below are the general specifications/performance characteristics we offer. If you have different requirements, do not hesitate to let us know.

Suitable for acidic environments in dyeing equipment.

Alumina ceramic eyelets: up to 1600°C; zirconia ceramic eyelets: up to 1000°C.

Compatible with machinery up to 25,000 RPM.

Mirror-polished (Ra ≤0.4μm) to reduce yarn abrasion.

High-quality Service for You

Ceramic Eyelets by Jinghui are precision-engineered components designed mainly for textile machinery, offering low friction, high wear resistance, and corrosion protection. Made from advanced materials like alumina and zirconia, these parts ensure smooth yarn handling, minimize fiber damage, and extend machinery lifespan. Ideal for spinning, weaving, and dyeing processes, they reduce downtime and energy consumption. With ISO 9001 certification and 15+ years of expertise, Jinghui delivers custom ceramic eyelets tailored to OEM specifications, trusted by global clients in automotive, aerospace, and industrial sectors.

Ceramic eyelets offer 10x longer lifespan, 30% lower yarn breakage, and corrosion resistance, outperforming metal eyelets in harsh environments like dyeing and high-speed spinning.

The ZrO₂ cerami eyelets has been tested to withstand linear speeds of >35 m/s (industry average is 20-25 m/s). The key design features include a parabolic curve for the inner channel to reduce turbulence, and a polished surface to minimize the coefficient of friction (μ < 0.15).

Use a tapered guide sleeve for insertion to prevent direct contact between the metal clamp and the ceramic; a polyurethane spacer is recommended to distribute the pressure.

Absolutely. We can provide excellent products in time to match OEM requirements, ensuring seamless integration into existing systems.