Technical SPECs

Ceramic crucibles have four major application areas: laboratory, metallurgy, semiconductor and energy. Their technical specifications are as follows:

Ceramic Crucible Manufacturing Expert

Ceramic crucibles by Jinghui are engineered for extreme thermal and chemical resistance. Crafted from high-purity alumina (Al₂O₃) or zirconia (ZrO₂), our crucibles withstand temperatures up to 1600°C, ensuring reliable performance in melting, sintering, and analytical processes. With 15+ years of expertise and ISO 9001 certification, we deliver crucibles trusted by labs, foundries, and electronics manufacturers worldwide.

By Features

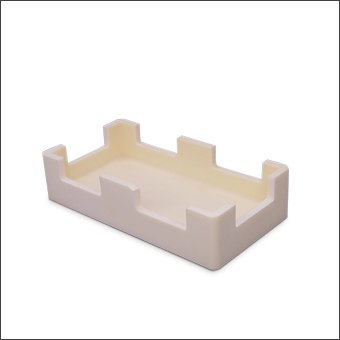

We have many types of ceramic crucibles, most of which are customized according to customer needs. The following products are available for your customization or selection reference.

High-purity alumina for non-reactive metal melting (Au, Ag, Pt) up to 1600°C.

Thermal shock-resistant sagger for kiln-based ceramic sintering and glaze firing.

Uniform heat distribution for lab experiments and small-batch alloy casting.

Insulating crucibles for high-voltage electrical testing and component coating.

Precision pouring spout for controlled molten metal transfer in jewelry manufacturing.

Zirconia-based crucibles for titanium and reactive metal melting under inert gas.

Grooved surface for secure wafer placement in semiconductor CVD processes.

Mullite crucibles for analytical chemistry and ash content testing.

Key Benefits

Jinghui can provide competitive ceramic crucibles to help your business grow.

Can be reused more than 100 times at low temperature (<1200℃).

Zero contamination for sensitive processes (e.g. precious metal melting).

Great performance at an affordable price.

Cylindrical, rectangular, conical, or custom shapes with lids.

Polished or glazed interiors for easy cleaning.

Functional samples in 10 business days.

High-quality Service for You

Our ceramic crucibles combine high-temperature resilience, chemical inertness, and longevity for demanding industrial and laboratory applications. Our ISO 9001-certified manufacturing ensures precision and reliability, while customizable designs meet unique process requirements.

Trusted by metallurgists, researchers, and semiconductor engineers, Jinghui’s crucibles minimize contamination risks and operational downtime. Partner with us for solutions that elevate efficiency and precision in your high-temperature processes. Contact us today to discuss your needs.

From cost consideration, the most suitable is the alumina crucible (purity above 99.5%), but it needs to be used under the protection of an inert atmosphere (such as Ar, N₂) and the temperature must be strictly controlled (it is recommended to increase or decrease the temperature by ≤5°C/min).

Ceramic crucibles can be heated directly, but preheating is recommended to avoid thermal shock cracking, especially for high-purity Al2O3 and SiO2. Due to their relatively poor thermal shock resistance, sudden cooling and heating are prone to thermal stress cracking. They should be heated gradually (5-10℃/minute) and cooled with the furnace.

Before using a new crucible for the first time, it is recommended to burn it empty to stabilize it and avoid local overheating with open flames. Check for cracks before using it to ensure safety.

If there are only slight scratches on the surface and it does not involve high temperature or corrosive environment, it can be used with caution for a short period of time, but it needs to be closely observed. If it is a slight crack, it is not recommended to continue using it. The main reasons are as follows:

1. Safety hazards: Cracks may expand rapidly at high temperatures, causing the crucible to suddenly break, causing molten material leakage or equipment damage.

2. Performance degradation: Cracks will reduce the mechanical strength and heat resistance of the crucible, affecting experimental accuracy or process stability.

3. Pollution risk: Impurities may peel off from the damaged area and contaminate the smelting materials (such as metals, chemicals, etc.).

Standard orders ship in 3-5 weeks. Expedited options are available for urgent needs.