Capable of Grinding Various Ingredients

High-quality ceramic burrs can grind a wide variety of ingredients. Below is a detailed ingredient guide.

- Perfect Match: Ceramic burrs are ideal for grinding black/white/red peppercorns, Sichuan peppercorns, dried chili peppers, caraway/coriander/cumin/fennel seeds, salt, and pour-over coffee beans.

- Extended Applications: Provided the ingredients are dry, low-oil, and moderately hard, they can also be used to grind small amounts of colored peppercorns, sesame seeds, etc.

- Professional Tip: For optimal flavor and to avoid flavor mixing, it is recommended to use dedicated grinders for salt, coffee, and spices.

Your #1 Choice for Ceramic Burrs in China

Jinghui has over 17 years of experience in the developing and manufacturing of a variety of standard and custom ceramic burrs. We supply burrs to reputable, large-scale grinder manufacturers in Europe, Asia, Africa, and North America.

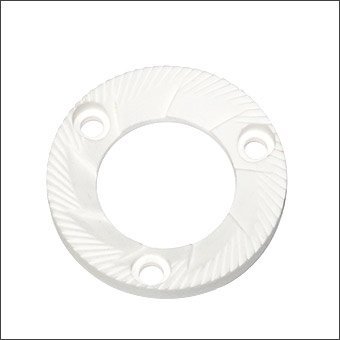

We produce both conical and flat ceramic burrs. They are wear-resistant, rust-free, sharp, stable in performance, FDA- and LFGB-certified, and suitable for various pepper, salt, and coffee grinders.

In addition to ceramic burrs, we also offer some standard ceramic grinder mechanisms. Sold as kits, they are an essential accessory for pepper grinders and have been successfully used by numerous international customers.

Our prices are very competitive and meet market demand for high cost-performance. If needed, we can provide free samples for your quality inspection.

Welcome to discuss cooperation with us.

By Application

We offer ceramic burrs for pepper grinders and coffee grinders, which can be customized to customer requirements. In addition, we also supply a variety of pepper mill grinder mechanisms.

The key component of the related grinders in the kitchen such as coarse salt, pepper, spices, etc.

Key component of coffee grinders and commonly found in both commercial and home applications.

Kits for our customers with convenient choices for application needs.

CKD method provides our clients with a more flexible purchasing method.

Featured Products

Our ceramic burrs have been successfully applied by many customers and have become an indispensable part of their products. Some standard models are listed below.

Key Benefits of Ceramic Burrs

The ceramic burr is one of our earliest products. It offers multiple outstanding advantages. We hope it will become one of the selling points of your product.

Non-reactive, ideal for seasoning and coffee.

5x lifespan vs. steel burrs.

Resistant to rust and corrosion.

Flat, conical, or hybrid geometries for OEMs.

Optimized for coarse/fine grinding.

Flexible MOQ and ISO-certified QC.

Design and Development Capability

● Configuration development: Optimized positioning and location design of burrs for imaging assembly machines of grinders.

● Size accuracy design: Ideal fitting dimensional tolerance, as well as suitable for bulk production.

● Grinding teeth design: Including the sizes, angle, density of the teeth, and the gaps between the inner and outer burrs.

Manufacturing Strength

※ Molds and dies can be customized according to specifications or actual samples.

※ 40 sets of auto shaping machines, monthly capability up to 10 million.

※ 5 sets of standard high-temperature sintering furnaces, and the output can be 12 million monthly.

Quality Assurance System

Everything is based on the ISO 9001:2015 quality management system.

● Incoming material inspection:

The particle size, specific surface area, particle morphology, and impurity content of each new batch of ceramic powder must be inspected to ensure stability.

● Process control:

Every process has IPQC checking, and complete automatic camera imaging systems are introduced into the final inspection covering profile, appearance, and dimensions of ceramic gears.

● Food-grade safety control:

Each kind of ceramic grinders will be sent to 3rd party to do food-grade safety testing per FDA, LFGB, and EEC regulations.

More About Our Ceramic Burrs

We can customize ceramic burrs for grinding pepper, salt, or coffee according to your requirements. They are manufactured from high-purity alumina or steatite ceramic, offering excellent wear resistance at an affordable price. In addition to custom-made ceramic burrs, we also offer several standard-type pepper mill grinder mechanisms. Many customers are amazed by our superior quality, and some have been working with us for over 10 years.

- Material Properties

- Comparison

- Burr Types

- Customization Capabilities

Ceramic burrs used for grinding spices like pepper and salt are typically made of alumina (95%/99% Al2O3) or steatite. Ceramic burrs used for grinding coffee beans are generally made of alumina (95%/99% Al2O3).

| Optional Materials for Ceramic Burrs | |||

| Mechanical Property | 99% Al2O3 |

95% Al2O3 |

MgO·SiO2 (Steatite) |

| Density (g/cm³) | ≥3.80 | ≥3.65 | ≥2.70 |

| Water Absorption (%) | 0 | 0 | 0 |

| Vickers Hardness (HV) | ≥1380 | ≥1520 | 580 |

| Flexural Strength (MPa) | ≥280 | ≥310 | ≥140 |

| Compressive Strength (MPa) | 2068 | 2160 | >551 |

| Fracture Toughness (MPa·m1/2) | 4-5 | 4-5 | 1.9 |

Still struggling to decide between ceramic burrs and steel burrs? The table below provides a quick guide.

| Ceramic Vs. Steel Burrs | |||

| Property | Ceramic Burr | Stainless Steel Burr | Carbon Steel Burr |

| Corrosion Resistance | ⋆⋆⋆ | ⋆⋆ | ⋆ |

| Cost Advantage | ⋆⋆⋆ | ⋆⋆ | ⋆ |

| Sharpness | ⋆⋆ | ⋆ | ⋆⋆⋆ |

| Durability | ⋆⋆ | ⋆⋆⋆ | ⋆⋆⋆ |

| Consistency | ⋆⋆ | ⋆ | ⋆⋆⋆ |

| Remark: The better the performance, the more stars. | |||

There are three common types of coffee grinder burrs on the market: blade, conical, and flat burrs. Want to know their respective pros and cons? See the table below.

| Types of Coffee Grinder Burrs | ||

| Blade | Conical Burr | Flat Burr |

| Cheap. Messy. Inconsistent grind. |

Quieter. More consistent grind. Good for home use and espresso. |

More expensive. Remarkably even particle size. Best for commercial use. |

We have extensive experience in the design and manufacture of ceramic burrs. Please feel free to contact us if you have any custom requirements.

1. Common Sizes

- Pepper/Salt/Spice Grinder Burr: 25~50mm (outer diameter), 10~20mm (thickness)

- Coffee Grinder Burr: 38~64mm (outer diameter), 7~20mm (thickness)

2. Shaft Interface

Square, hexagonal, D-shaped, special tooth profiles, etc.

3. Overall Structure

Conical or flat

4. Tooth Profile Design and Performance

- We can optimize the tooth geometry for different spices such as peppercorns, chilies, and sesame seeds.

- We can tailor our designs to meet specific customer requirements, such as the size of the peppercorns to be ground and the desired particle size of the resulting powder.

Related Products

Ceramic burrs are a pair of ceramic cones (or discs) with coarse and fine teeth. They work by using the shearing and grinding pressure generated by the relative rotation of the two cones (or discs) to break down ingredients into uniform particles.

Ceramic is not only hard but also naturally pure, never rusts, and will never affect the authentic flavor of coffee beans or spices.

Ceramic burrs can grind ordinary refined table salt, dry fine sea salt, and coarse sea salt for cooking. However, it cannot be used to grind wet, large-particle rock salt or mineral salt, as this may cause physical damage, blockage and clumping, and increased wear.

We cannot make any guarantees without knowing the specific structure of your grinder. Generally speaking, as long as your grinder uses standard-sized, replaceable ceramic burrs, our products are highly likely to be compatible. However, to be on the safe side, if you are purchasing in bulk, we recommend ordering a small quantity of samples for trial installation first.

If you use custom ceramic burrs, you will need to send us the drawings. We will assess the feasibility of production and provide you with a quote.

Rinse with water (no detergents) and dry thoroughly. Avoid grinding extremely hard materials (e.g., stones) to prevent chipping.

Yes, we have a grinder mechanism that comes with ceramic burrs and a stainless steel shaft. It’s perfect for grinding salt. Please contact us to learn more.

Technically it’s possible, but we don’t recommend it. The most serious problem is flavor contamination. Both pepper and coffee are intensely flavorful ingredients and absolutely cannot share a grinder without mixing flavors. Then there’s the issue of mismatched grind designs. Coffee flavor extraction requires extremely high particle uniformity, while pepper grinding doesn’t demand such uniformity. Finally, there’s the cleaning problem. The oils in coffee and the aromatic oils in pepper cannot be removed by simple rinsing.

Ceramic burrs are safe for everyday use. They are non-toxic, stable, corrosion-resistant, and do not easily damage the flavor of ingredients (such as coffee beans and pepper) during grinding. They are also washable.

Furthermore, our ceramic burrs have food contact material testing reports from authoritative laboratories and meet US FDA and EU food safety standards.

Yes, we can customize ceramic burrs. Our customization services include shape and specifications, tooth patterns and specific properties (such as the particle size of the ground powder), and laser marking. If you have any customization needs, please contact our customer service team directly via email or phone.

Some standard products are in stock. We can ship them within 2-3 business days. The standard lead time for customized products is 4-6 weeks.

We will provide a specific delivery time once you confirm your order.