Aluminum Nitride Substrate Processing Techniques

The processing techniques for the aluminum nitride substrate mainly include cutting, drilling, grinding, polishing, and metallization.

- Cutting: Cut large aluminum nitride plates into smaller sizes.

- Drilling: Machining through holes or blind holes on the substrate.

- Grinding and polishing: Improving flatness and smoothness of the substrate surface.

- Metallization: Deposition of metal layers on the substrate surface for electrical connection.

Your Reliable Partner for Aluminum Nitride Substrates

Jinghui has been supplying aluminum nitride (AlN) substrates since 2008. Our AlN substrates combine exceptionally high thermal conductivity with outstanding insulating properties, making them ideal for demanding electronic applications such as microelectronics, LED packaging, power electronics, semiconductor manufacturing, and microwave and RF components.

Why Choose Us?

- Technical Values: Custom sizes and finishes to meet your unique needs; Efficient heat dissipation for enhanced device performance.

- Rigorous Quality Control and Competitive Pricing: Premium quality at cost-effective rates.

- Fast Delivery: Reliable delivery to meet your tight deadlines.

Contact us today for a quote and experience the difference of working with a trusted global supplier in AlN substrates.

By Features

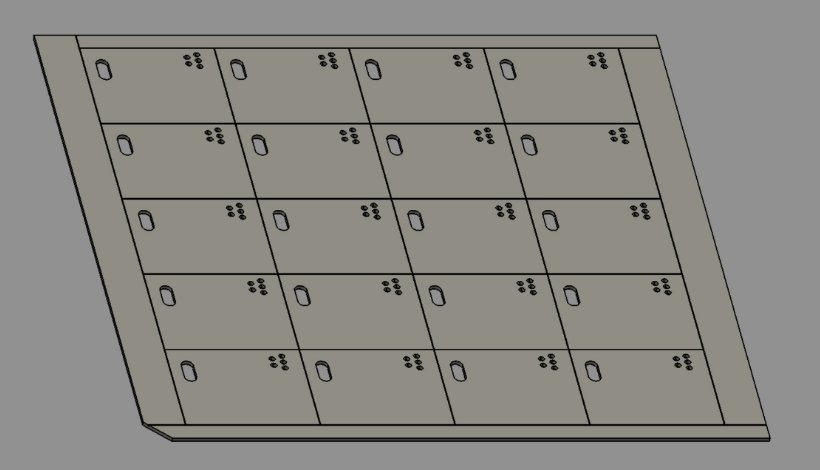

You can find various types of aluminum nitride substrates in different sizes, shapes and processes.

The most common sizes are 50.8*50.8mm, 114*114mm and 140*190mm.

Larger size highlights production capabilities, e.g. a φ150mm AlN wafer.

The surface is polished to achieve extremely high smoothness and flatness.

Use laser cutting, drilling or engraving to achieve complex structures.

How Difficult Is It to Process Aluminum Nitride Substrates?

Aluminum nitride substrates are challenging to work on in the following 2 ways.

1. High hardness and brittleness

Aluminum nitride is a high-hardness and high-brittle ceramic material with a hardness close to that of diamond. This characteristic makes traditional processing methods difficult to apply, and requires the use of high-hardness tools (such as diamond tools) and special processing techniques (such as laser cutting). During the processing, the slightest carelessness may cause material breakage or edge damage, so the control requirements for processing equipment and process parameters are extremely high.

2. High-precision requirements

Aluminum nitride substrates are usually used in precision fields such as high-power electronic devices and radio frequency devices, and have very high requirements for dimensional accuracy, surface flatness and finish. This places extremely high demands on the resolution, stability of processing equipment and the skills of operators.

The thermal conductivity of aluminum nitride substrates is generally 170-230 W/(m·K), significantly higher than that of aluminum oxide substrates (approx. 24 W/(m·K)) and close to that of beryllium oxide substrates (approx. 250 W/(m·K)), although beryllium oxide is toxic.

This high thermal conductivity makes aluminum nitride substrates an ideal choice for cooling high-power electronic devices. They can quickly transfer heat from the chip to the heat sink, significantly reducing device temperatures and improving reliability and lifespan.

Aluminum nitride substrates feature high resistivity (>10¹³ Ω·cm) and low dielectric constant (8-9), enabling effective circuit isolation and reduced signal loss. Their outstanding electrical insulation properties deliver exceptional performance in high-frequency, high-power electronic devices, ensuring stable and efficient signal transmission.

Aluminum nitride substrates exhibit higher mechanical strength than alumina substrates, enabling them to withstand greater mechanical and thermal stresses. Their flexural strength typically exceeds 310 MPa, making them suitable for applications demanding high reliability, such as automotive electronics and aerospace equipment.

Aluminum nitride substrates cost more than alumina substrates, but their excellent overall performance (such as high thermal conductivity and low thermal expansion coefficient) makes them more cost-effective in high-performance applications. For high-power, high-frequency, and high-reliability applications, aluminum nitride substrates are one of the most cost-effective options.

Yes, we can customize aluminum nitride substrates according to your requirements. Customization options include size, shape, finish, and more. Standard sizes include 50.8*50.8mm, 114*114mm, 140*190mm, etc., and the thickness range is usually 0.2-1.5mm. For special applications, larger sizes or thinner/thicker substrates can also be provided.

Aluminum nitride substrates are an environmentally friendly material, free from harmful substances such as lead, cadmium, and mercury, and compliant with environmental regulations including RoHS and REACH.

Compared to beryllium oxide substrates, aluminum nitride substrates are non-toxic and harmless to both humans and the environment, making them an eco-conscious choice for high-performance applications.