AlN, Non-toxic Alternative to BeO

AlN has similar thermal and electrical properties to BeO, but is more economical and has no toxicity issues, so it can replace BeO in some areas.

- Thermal conductivity of AlN (170-230 W/(m∙K)) is close to that of BeO (250 W/(m∙K))

- AlN has higher flexural strength, fracture toughness, and hardness than BeO, and is less brittle.

- BeO has a higher thermal expansion coefficient than AlN, which may cause greater thermal stress in environments with large temperature changes.

China Aluminum Nitride Plate Supplier

Jinghui is a professional aluminum nitride plate Chinese supplier. Our products’ core performance advantages include high thermal conductivity (170-230 W/(m∙K)), high electrical insulation, low thermal expansion coefficient (close to that of silicon) and excellent mechanical strength.

These properties make it excellent in fields such as high-power electronics, industrial heating equipment, and aerospace. High thermal conductivity ensures efficient heat dissipation and prevents device overheating; high insulation ensures safety in high voltage environments; low thermal expansion coefficient reduces thermal stress and improves device reliability. In addition, its thickness is usually above 1.0mm, which is suitable for applications that require high mechanical strength.

We ensure product consistency and durability through strict quality control. If you choose us, you’ll benefit from good quality, competitive pricing, customizable solutions, and fast delivery. Contact us today for a quote.

Product By Features

We supply the following types of aluminum nitride plates. Some sizes are available from stock and can be cut to smaller sizes upon request.

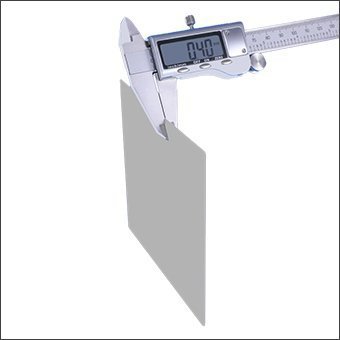

Thickness ≤ 1mm. Suitable for scenarios that require rapid heat dissipation.

Thickness 1-3mm. It is a very practical specification in industrial applications.

Thickness ≥ 3mm. For scenarios requiring high mechanical strength.

For cutting-edge applications requiring precision heat dissipation and a tight fit.

Aluminum Nitride Plate Thickness Selection and Application Guide

Aluminum nitride plates are widely used in high-power electronics, LEDs, electric vehicles, and industrial equipment due to their high thermal conductivity, high electrical insulation, and low thermal expansion coefficient. However, different application scenarios have different requirements for the thickness of ceramic plates, and the thickness selection directly affects their heat dissipation performance, mechanical strength, and application effect.

This article provides you with a thickness selection guide for aluminum nitride plates in different scenarios to help you optimize your design, give full play to the material properties, and meet diverse needs.

- Consumer Electronics (Such as Smartphones, Tablet Computers)

Recommended thickness: 0.3mm – 0.8mm

Reason: Consumer electronics require heat dissipation materials to be thin and efficient. Aluminum nitride substrates with a thickness of 0.3mm-0.8mm can achieve efficient heat dissipation in a limited space while keeping the device lightweight.

- LED Chip Heat Dissipation Substrate

Recommended thickness: 0.3mm – 1.0mm

Reason: LED chips have high requirements for heat dissipation, but the space is limited. Aluminum nitride substrates with a thickness of 0.3mm-1.0mm can achieve efficient heat dissipation in a limited space while maintaining lightweight.

- RF and Microwave Device Packaging

Recommended thickness: 0.5mm – 1.2mm

Reason: RF and microwave devices require materials with low dielectric constant and low loss, and also require certain heat dissipation performance. Aluminum nitride sheets with a thickness between 0.5mm-1.2mm can meet these requirements.

- High-Power Electronic Devices (Such as IGBT, MOSFET, SiC/GaN Power Modules)

Recommended thickness: 0.5mm – 1.5mm

Reason: High-power electronic devices require efficient heat dissipation performance. Thinner ceramic sheets (such as 0.5mm-1.0mm) can reduce thermal resistance and improve heat dissipation efficiency. For scenarios that require higher mechanical strength, the thickness can be increased to 1.5mm.

- Medical Equipment (Such as Laser Medical Equipment)

Recommended thickness: 0.8mm – 2.0mm

Reason: Medical equipment has high requirements for material reliability and heat dissipation performance, and also requires lightweight design. Aluminum nitride plates with a thickness of 0.8mm-2.0mm can meet these requirements.

- Electric Vehicle Power Modules (Such as Inverters, Motor Controllers)

Recommended thickness: 1.0mm – 2.0mm

Reason: Electric vehicle power modules need to work in high voltage and high power environments while withstanding mechanical vibration and thermal stress. Aluminum nitride plates with a thickness of 1.0mm-2.0mm can provide sufficient mechanical strength and heat dissipation performance.

- Solar Inverters and Wind Power Inverters

Recommended thickness: 1.0mm – 2.5mm

Reason: Solar and wind power inverters need to work in high power environments while withstanding temperature changes and mechanical stress in outdoor environments. Aluminum nitride plates with a thickness between 1.0mm-2.5mm can meet these needs.

- Laser Heat Sink

Recommended thickness: 1.0mm – 3.0mm

Reason: High-power lasers generate a lot of heat when working and require efficient heat dissipation performance. Aluminum nitride plates with a thickness between 1.0mm-3.0mm can provide sufficient heat dissipation capacity and mechanical strength.

- Aerospace Components

Recommended thickness: 1.5mm – 4.0mm

Reason: Aerospace equipment has extremely high requirements for material reliability and performance, and needs to withstand extreme temperatures and high vibration environments. Aluminum nitride plates with a thickness between 1.5mm-4.0mm can provide sufficient mechanical strength and heat dissipation performance.

- Industrial Heating Equipment (Such as High Temperature Furnaces, Heaters)

Recommended thickness: 2.0mm – 5.0mm

Reason: Industrial heating equipment needs to withstand high temperatures and mechanical loads while providing a certain degree of thermal insulation. Thicker aluminum nitride plates (such as 2.0mm-5.0mm) can meet these requirements.

Conclusion

By rationally selecting the thickness of aluminum nitride plates, we can maximize their performance advantages and meet the needs of different application scenarios.

Our company distinguishes aluminum nitride plates and substrates based on thickness. Generally, the thickness of aluminum nitride plates is above 1.0 mm, while the thickness of aluminum nitride substrates is below 1.0 mm.

In addition to different thicknesses, their applications are also different. Aluminum nitride plate is mainly used in scenarios that require higher mechanical strength, such as industrial heating equipment or support structures of high-power modules. And because aluminum nitride substrate is thinner and lighter, it is mainly used as heat dissipation sheet for high-power electronic devices, such as LED chips, semiconductor power modules, etc.

The common point between the two is that both have high thermal conductivity and high electrical insulation, but ceramic substrates focus more on heat dissipation performance, while ceramic plates focus more on structural strength and durability.

Compared to alumina plates, aluminum nitride plates have higher thermal conductivity and lower thermal expansion coefficient, making them more advantageous in high-power and high-reliability applications.

In electric vehicles, aluminum nitride plates (thickness above 1.0mm) are mainly used for supporting structures and heat dissipation components of power modules (such as inverters and motor controllers). Its high thermal conductivity and high insulation ensure the reliable operation of devices in high power and high voltage environments, while effectively dissipating heat and extending device life.

In addition, aluminum nitride substrates (thickness below 1.0mm) are used for heat dissipation substrates in battery management systems and charging piles to help solve heat dissipation problems under high power density.