Alumina Tube Manufacturing Experts

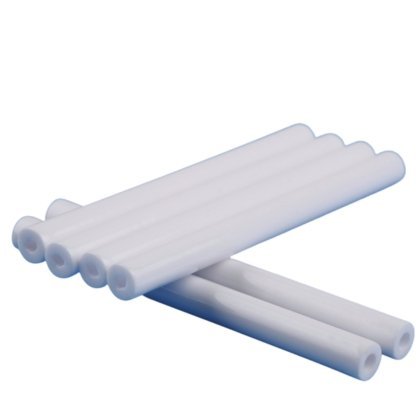

If you are looking for a professional alumina tube factory in China, Jinghui ceramic is your first choice. We have over 1000 styles of alumina pipe to support your business.

As a special advanced ceramics supplier since 2008, we have 10 expert designers and can supply 2D and 3D drawings based on your project needs or even ideas, you can customize your alumina tubes, just give your project details, and we will design free for you.

We can supply alumina tube with various length and diameter. Our ceramic tubes are also available in a variety of color options for meeting industry standards. Trust us to provide reliable, customizable solutions to you.

Product By Features

Alumina tube is a common product application of alumina ceramic materials. We are able to customize alumina tubes to your specifications in a variety of shapes, and these products below are just a few of our many offerings.

Product By Application

We offer a wide range of aluminum oxide tubes that are used in different usage scenarios utilizing its different properties.

Top-quality service for you

Alumina tubes, offered by Jinghui Ceramic, are high-performance ceramic components known for their exceptional thermal stability, corrosion resistance, and mechanical strength. Made from high-purity alumina (Al2O3), these tubes are ideal for demanding applications such as furnace linings, thermocouple protection, and semiconductor processing. While their extreme hardness requires specialized machining tools like diamond blades, their brittleness and sensitivity to thermal shock are minor trade-offs. Jinghui Ceramic ensures precision manufacturing, delivering reliable alumina tubes for industries like aerospace, metallurgy, and chemical processing. Trust Jinghui for top-quality alumina ceramic solutions tailored to your needs.

Yes, alumina tubes can be machined, but it requires specialized tools like diamond grinding wheels or laser cutting due to their extreme hardness. Precision machining is possible for tasks like drilling or shaping, but the process is slow and costly. Proper cooling and handling are essential to avoid cracking. Alumina’s brittleness makes it challenging, but skilled techniques ensure high-quality results.

To cut alumina ceramic tubes, use a diamond-coated cutting tool or a precision saw with a diamond blade for clean, precise cuts. Ensure proper cooling (e.g., water or coolant) to prevent overheating and cracking. Secure the tube firmly to avoid vibrations. For smoother edges, finish with diamond grinding or polishing. Always wear safety gear, including gloves and goggles, as ceramic dust can be hazardous. If high precision is required, consider laser cutting, though it may be more costly. Proper handling and tool selection are key to achieving clean cuts without damaging the tube.

Alumina pipes, while highly durable and resistant to heat and corrosion, have some disadvantages. They are brittle and prone to cracking under mechanical stress or impact. Their high hardness makes machining and cutting difficult, often requiring specialized tools like diamond blades. Additionally, alumina pipes are relatively heavy compared to metals or polymers, which can limit their use in weight-sensitive applications. They also tend to be more expensive due to the complex manufacturing process. Lastly, their low thermal shock resistance can cause failure under rapid temperature changes. Despite these drawbacks, alumina pipes excel in high-temperature and corrosive environments.

Alumina tubes are widely used in high-temperature applications, such as furnace linings, thermocouple protection, and semiconductor processing, due to their excellent thermal stability and corrosion resistance. They are also ideal for insulating components in electrical systems and as crucibles in laboratory settings. With high mechanical strength and wear resistance, alumina ceramic tubes are essential in industries like aerospace, metallurgy, and chemical processing. Their ability to withstand extreme environments makes them a reliable choice for demanding industrial and scientific applications.