Zirconia Material Overview

Zirconia ceramic, chemically known as zirconium dioxide (ZrO₂), is a polycrystalline advanced ceramic material stabilized with oxides such as yttrium oxide (Y₂O₃), magnesium oxide (MgO), or calcium oxide (CaO). These stabilizers enable zirconia to exist in monoclinic, tetragonal, and cubic crystal phases, each contributing to its outstanding mechanical and thermal properties.

Among all advanced ceramics, zirconia is unique due to its phase transformation toughening mechanism, which significantly improves crack resistance under mechanical stress. Because of this behavior, zirconia ceramic is often referred to as “ceramic steel”, making it suitable for demanding applications requiring high reliability and long service life.

The most commonly used zirconia ceramics include:

- Yttria-stabilized zirconia (YSZ)

- Magnesia-stabilized zirconia (MSZ)

The following table compares the key properties of YSZ and MSZ, helping engineers and designers select the appropriate zirconia ceramic grade for different operating conditions.

| Property | YSZ | MSZ |

| Density | 6.0 g/cm³ | 5.72 g/cm³ |

| Flexural Strength | 800 MPa | 750 MPa |

| Modulus of Elasticity (GPa) | 200 | 200 |

| Thermal Conductivity (W/m·K) | 3 | 2.2 |

| Max. service temperature (℃) | 1500 | 1500 |

| Dielectric Strength (kV/mm) | 9 | 9.4 |

Zirconia Ceramic Products & Forms

Zirconia ceramics can be easily formed into complex geometries in the green state. After full sintering, final dimensions and surface finishes are achieved through diamond grinding, CNC machining, or laser processing.

Common zirconia ceramic product forms include:

- Zirconia substrates

- Zirconia plates

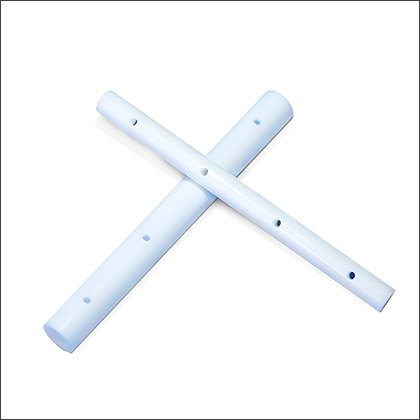

- Zirconia tubes

- Custom zirconia ceramic structural components

These forms are widely used in mechanical, chemical, electronic, and medical systems where high precision and durability are required. The following products show some of their uses in more product forms.

-

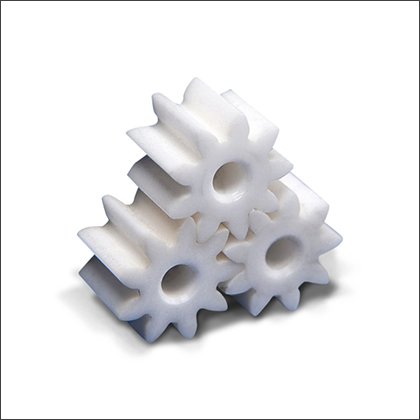

Zirconia Ceramic Gears

Zirconia Ceramic Gears -

zirconia Ceramic Blades

zirconia Ceramic Blades -

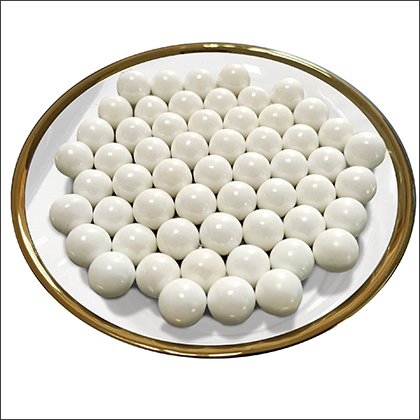

Zirconia Beads

Zirconia Beads -

Zirconia Ceramic Ring

Zirconia Ceramic Ring -

Zirconia Ceramic Sheet

Zirconia Ceramic Sheet -

Zirconia Ceramic Sleeve

Zirconia Ceramic Sleeve

Key Properties of Zirconia Ceramics

Compared with alumina ceramics, zirconia offers significantly higher fracture toughness, while compared with silicon nitride, zirconia provides better chemical inertness and biocompatibility. Zirconia ceramics offer the following key advantages:

Flexural strength up to 800 MPa, significantly higher than alumina and lithium disilicate ceramics.

Transformation toughening improves crack resistance, reducing the risk of sudden failure.

Continuous operation up to 1500 °C in air, suitable for high-temperature industrial environments.

Vickers hardness of 1070–1230 HV, ideal for abrasive and sliding applications.

Resistant to strong acids, alkalis, and corrosive media.

Widely used in dental restorations, hip implants, and medical devices due to excellent biocompatibility and low bacterial adhesion.

Applications of Zirconia Ceramic Materials

High-Stress Industrial Components

Zirconia ceramics are used to replace metals in non-lubricated environments to reduce friction and failure risks. such as:

- Pump components

- Valves and seals

- Bearings and wear parts

High-Temperature and Corrosive Environments

Zirconia maintains mechanical stability in:

- Strong acids and alkalis

- Hot gas flows

- Chemical processing equipment

This significantly extends equipment service life and reduces maintenance costs.

Energy and Electrochemical Devices

Zirconia ceramics play a critical role in:

- Solid oxide fuel cells (SOFC)

- Oxygen sensors

- Electrolytic cells

Cubic zirconia enables efficient oxygen ion conduction at elevated temperatures.

Related Advanced Ceramic Materials

-

Alumina ceramics are advanced ceramics with excellent comprehensive properties, and they were researched early, are the most widely used, and are the most mature.

-

Aluminum nitride ceramics are advanced ceramics with high thermal conductivity and insulation, and are often used in electronic packaging substrates and heat dissipation components.

-

Silicon carbide ceramics are advanced ceramics with semiconductor properties and resistance to high-temperature corrosion, making them suitable for power devices and high-temperature structural components.

-

Cordierite ceramics have ultra-low thermal expansion and are resistant to thermal shock, making them suitable for use as catalyst carriers and thermal insulation materials.

-

ZTA ceramics combine the hardness of alumina with the toughness of zirconia, making them suitable for cutting tools and wear-resistant components.

Custom Zirconia Ceramic Manufacturing

Customized zirconia ceramic solutions are available to meet specific application requirements.

-

Size and Geometry Customization

Precision machining after sintering using CNC grinding and laser cutting, with tolerances up to ±0.01 mm. -

Surface Treatment Options

Mirror polishing down to Ra 0.1 μm, suitable for sealing surfaces and optical or medical components.

Zirconia ceramics have a Mohs hardness of approximately 8.5–9, comparable to alumina ceramics and significantly harder than ordinary steel.

Thanks to its high fracture toughness (6.5–11 MPa·m¹/²), zirconia is not easy to break and performs reliably in high-stress applications.

- Pharmaceuticals: Zirconia plunger pumps resist acids (e.g., HCl) and alkalis, ensuring zero drug contamination during liquid filling.

- Energy: Solid oxide fuel cells use cubic zirconia electrolytes for efficient oxygen ion conduction at elevated temperatures (typically 700–1000 °C).

- Semiconductors: Zirconia crucibles handle molten silicon without reactivity, critical for wafer production.

Beyond its renowned toughness and biocompatibility, Zirconia (ZrO2) ceramic is a versatile engineering solution pushing the boundaries of performance across sectors. The potential uses are vast, but they converge on one goal: solving complex engineering problems.

1. Electronics & Semiconductors: In insulating substrates, sensor components, and wafer processing parts, thanks to its excellent dielectric properties.

2. Industrial Automation: As pump seals, ball valves, and cutting tools that withstand extreme abrasion and corrosion.

3. Medical & Dental: From wear-resistant hip joint bearings and dental implants that promote osseointegration.

4. Automotive: For oxygen sensors, engine components, and wear parts that perform under high temperatures.

5. Consumer Goods: Enabling durability in precision knives, watch cases, and sporting goods.

The table below summarizes how key properties of zirconia ceramics translate into specific industrial applications and performance benefits.

| Key characteristics | Potential Uses | Bullet points & Value |

| Toughness & fracture resistance strength | • Ball Valves and Seats in corrosive fluids• Cutting Tool Inserts for non-ferrous metals

• Wear Liners and Guides |

• Reduce downtime and maintenance costs• Extend component life and lower total cost of ownership

• Improve machining accuracy |

| Biocompatibility & wear resistance | • Orthopedic Implants (hip, knee)• Dental Abutments and Bridges

• Surgical Tool Components |

• Improved patient outcomes and implant longevity• Excellent tissue response, reducing the risk of rejection

• Withstands repeated sterilization |

| Low thermal conductivity & high temperature resistance | • Thermal Barrier Coatings for engine parts • Furnace Components • Engine Sensors |

• Improve thermal efficiency and protect metal substrates • Maintain dimensional stability in extreme environments • Enable precise sensing and control |

| Excellent dielectric properties | • Semiconductor Wafer Handling Pins • RF Connectors and Substrates • Piezoelectric Actuators |

• Prevents contamination and electrostatic damage • Ensures signal transmission integrity • Enables precise positioning and control |

YSZ offers higher ionic conductivity, making it ideal for SOFC and precision components.

MSZ provides better thermal shock resistance and dimensional stability in large or thick-walled industrial parts.