Why Choose Jinghui

- A wide range of technical ceramic materials for plates

- Integrated shaping methods for specific applications

- Customize any sizes and configurations per your needs

- Sufficient stock with flexible delivery for standard plates

- Quick-turn and affordable prototyping for R&D samples

- Free samples of standard plates for quality assessment

Your Reliable Industrial Ceramic Plates Manufacturer

As a deep cultivator of industrial ceramics, our factory focuses on manufacturing a wide range of high-performance industrial ceramic plates, providing customized solutions to customers worldwide.

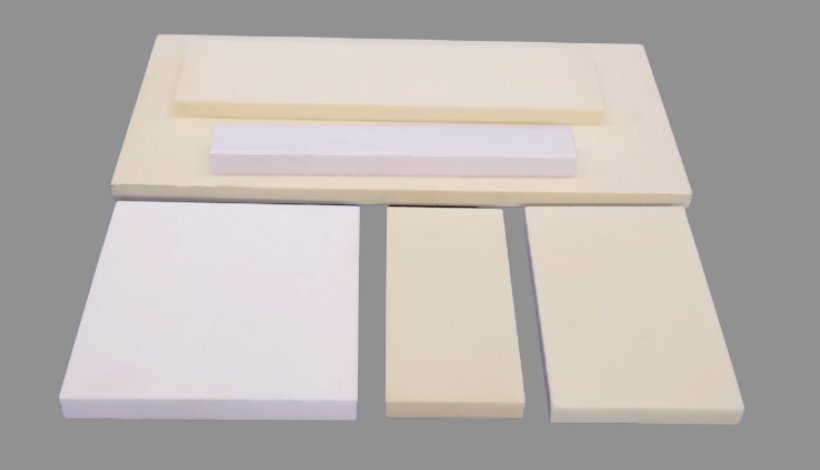

We also have in-house hot and isostatic pressing based on dry pressing as a shaping process. This allows us to produce a variety of custom complex-structure plates and products from small to large sizes. Given all ceramic materials can be formulated and sintered internally, it leads us to provide you with more competitive solutions.

In addition, another core strength of ours is the supply of ceramic plates from a variety of different raw materials. The material purity of the alumina plates we supply can be as high as 99.7%, making them a model for high-temperature resistance, insulation, and high-wear resistance industry applications; Zirconia plates break through the limits of mechanical components with 2200MPa bending strength. Aluminum nitride plates reconstruct the heat dissipation solution with CTE of 200W/m·K. Besides, these typical technical ceramic plates, we also produce silicon nitride, boron nitride, macor and mullite plates.

If you are searching for industrial ceramic plates, don’t hesitate to reach out us. You will find an optimized solution here as well as a reliable long-term partner.

By Material

As different advanced ceramics materials offer distinct merits, which are suitable for different applications in the industries. Therefore, we can make ceramic plates in a selection of ceramic materials for your specific solution.

A most used fine ceramic material for making industry plates because of its well-balanced properties and cost

Higher purity of alumina stands for higher performance, 99.8% alumina plate is suitable for various high-end industries.

Silicon nitride plates stand out in their unmatched thermal shock and high hardness in industrial applications.

Aluminum nitride plates are featured with excellent thermal conductivity for high-power modules.

Zirconia plates are characterized by their fracture toughness and excellent abrasive resistance than others in the family.

Boron nitride plates combine high thermal conductivity, high electrical insulation, and self-lubrication in comparison with others.

Macor sheet is known for its easier machinable property, so it is more used for custom-machined than other technical ceramic materials.

Silicon carbide plate is ideal for high thermal conductivity, electrical insulation, high temperature resistance and chemical stability.

By Features

Due to the diversity of needs in modern industries, these industries ask for matched ceramic components that offer corresponding features to accomplish the function and performance target in the system, even elevate them.

The max. outer diameter we can reach is 350mm via isostatic pressing. All these large-size plates have ideal flatness after fine grinding.

To obtain smoother and finer surface quality, polishing is a necessary method to elevate the flatness and roughness.

Applying a layer of glaze onto industrial ceramic plates increases the electrical insulation and mechanical strength significantly.

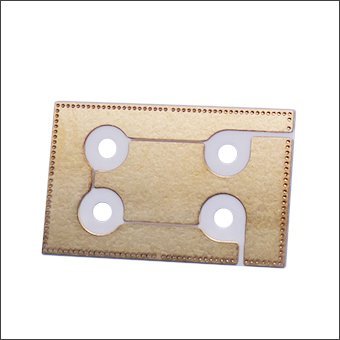

When the thickness of industrial ceramic plates is less than 1.2mm, the laser cutting process can conduct onto thin sheet to get complex pattern.

To achieve high-precision fitting and installation in the applications, it requires very tight dimensional tolerances. So machining is a must to conduct.

In most cases, the ceramic wafers must be polished and precisely ground to ensure the surface quality for semiconductor uses.

Due to the chromium additive in the alumina mixture, the color of the Al2O3 plate is red. The lapped plates are commonly used in electrical circuits.

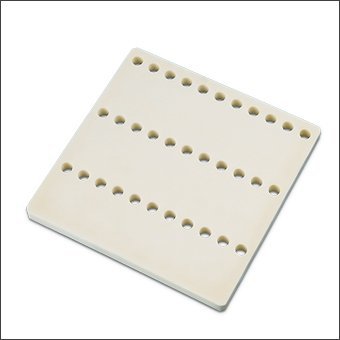

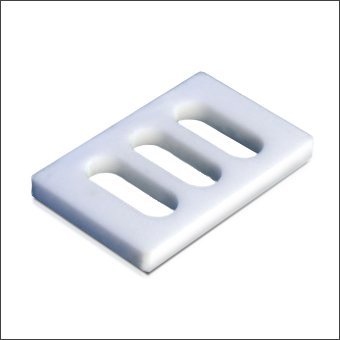

As technical ceramic plates are the most universal industrial component, thus, various custom geometries, sizes, and surface finishes are needed.

By Applications

Our ceramic plates have a wide range of applications, making the most of the properties of ceramics materials themselves.

-

It takes advantage of technical ceramics’ ideal thermal conductivity, used in various MOSFETs.

-

Technical ceramics are an ideal choice of electrical insulation material, especially for alumina and steatite

-

Industrial ceramic setters are regularly made from high-purity alumina, aluminum nitride, and silicon nitride.

-

Thanks to the superb hardness and abrasive resistance of alumina. They are widely used as lining tiles.

-

Ceramic Bulletproof Plate

Ceramic Bulletproof PlateCeramic bulletproof plates are the most common use of technical ceramics in military and defense.

Top 5 Materials of Industrial Ceramic Plates

- Alumina (Al2O3) Plate

Al2O3 plate is made from aluminum oxide and take the largest share in the modern industries. This ceramic component posses well-balanced properties and cost advantage than other types of advanced ceramics.

Thanks to the exceptional high hardness, abrasive resistance and electrical insulation of alumina plate, they are widely used in electronics & electrical, machinery manufacturing and chemistry fields.

- Silicon Nitride (Si3N4) Plate

Si3N4 plate takes important position in the high-performance, especially automobile, aviation and aerospace industries because of high physical strength and extraordinary thermal shock resistance . They are always used as high-temp ceramic structural parts and engine components.

- Silicon Carbide (SiC) Plate

Since the exceptional high heat conductivity, high melting point, corrosion & erosion resistance and chemical stability of silicon carbide ceramic, that’s why SiC plate can stands out in the new energy and semiconductor industries.

- Boron Nitride (BN) Plate

Boron Nitride is featured with its high thermal conductivity with fast heat dissipation, super electrical insulation, chemical stability and high-frequency attributes. Thus, boron nitride plate are mainly used in high-end electronics and thermal management industries.

- Zirconia(ZrO2)Plate

Zirconia is characterized by its high fracture toughness, high durability and biocompatibility in the advanced ceramic family. They are extensively used as medical & dental crown, industrial wear parts, electronics and energy and High-end decorative materials, smart wearable parts.

To sum up, industrial ceramic plates will play unparalleled roles in these future promising industries, such as new and renewable energy, semiconductor and electronic equipment manufacturing, biotechnology and health care, space technology and commercial spaceflight. The technical ceramic component will empower these high-tech industries to break through their limits.

Industrial ceramic plates are very different from traditional ceramic plates for daily use. They are made of high-performance advanced ceramic materials through unique molding and ultra-high-temperature firing. The main types of ceramic materials include aluminum oxide (Al2O3), zirconium oxide (ZrO2), silicon nitride (Si3N4), silicon carbide (SiC), aluminum nitride (AlN), and Bore Nitride (BN).

Almost all high-purity industrial ceramic plates offer high-temp resistance, high mechanical strength, wear resistance and anti-corrosion performance and so on. Due to their distinctive properties of different types of ceramic material, they exhibit different virtues, for example aluminum nitride owns super high thermal conductivity, zirconia and alumina are non-toxic, inert and biocompatible, silicon nitride has exceptional thermal-shock resistance.

Industrial ceramic plates usually have better high-temperature resistance than metals due to their unique properties and microstructure, refer to the comparison table for service temperature of typical technical ceramics:

| Types of ceramic | Max. Working Temp in the air

(Without loading) |

Max Working Temp. in the inert |

| Al2O3 | 1650℃ | 1800℃ |

| Si3N4 | 1000~1400℃ | 1800~1900℃ |

| SiC | 1000~1600℃ | 1600~1700℃ |

| BN | 900℃ | 2800℃ |

| ZrO2 | 1000~1100℃ | – |

All Industrial ceramic plates are safe and eco-friendly. They fully meet FDA, LFGB, RoHS and REACH regulations, also they are eco-friendly and recyclable.