Technical SPECs

Our ceramic shafts are mainly made of two materials: alumina with a purity of more than 99% and zirconia.

| Property | Alumina (≥99%) | Zirconia (3Y-TZP) |

|---|---|---|

| Density | ≥3.8 g/cm³ | ≥6 g/cm³ |

| Flexural Strength | ≥310 MPa | ≥800 MPa |

| Thermal Conductivity | 29 W/m·K | 2–3 W/m·K |

| Surface Finish After Machining | Ra ≤0.2 µm | Ra ≤0.1 µm |

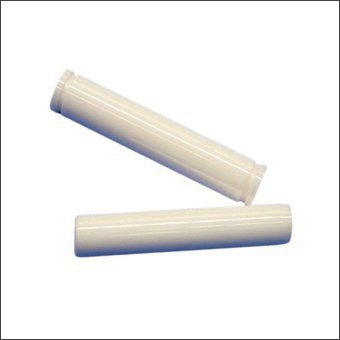

Professional Manufacturer of Precision Ceramic Shafts

As a professional ceramic shaft manufacturer, we provide ceramic shafts made of various materials such as alumina and zirconia. They have core advantages such as ultra-high wear resistance, corrosion resistance, insulation, and lightweight. They are suitable for chemical pump shafts, food machinery, textile guide wheels, precision instruments and other scenarios, greatly reducing maintenance costs and extending equipment life!

By Features

Our ceramic shafts are customized according to customer requirements, with different features. Typical products are as follows.

High wear resistance for textile machinery, reducing fiber breakage and energy consumption.

High rigidity and low thermal expansion ensure long-term accuracy.

Balances strength and thermal stability for hybrid EV powertrains.

Ultra-low thermal expansion, used in semiconductor wafer handling robots.

Fracture toughness 6–8 MPa√m for silicon nitride, ideal for CNC spindles.

Low friction (μ≈0.2) for food processing and automotive transmissions.

Resists acids/alkalis for chemical pumps and pharmaceutical equipment.

0.5–5 mm diameter for medical endoscopes and microfluidic devices.

Performance Characteristics

In the case of precision transmission and harsh working conditions, traditional metal shafts are prone to wear, corrosion and short life. High-performance ceramic shafts provide better solutions for industrial applications with excellent material properties!

99% alumina ceramic has a Vickers hardness of 1700 HV and reduces wear by 90% compared to steel.

Operate continuously at 1600°C (Al₂O₃) or 1000°C (ZrO₂), ideal for high-temperature applications.

Resistant to acids, alkalis, and molten metals, ensuring durability in corrosive environments.

The weight of rotating parts is reduced by 30%-50%, which reduces the starting torque and saves motor energy consumption.

Ceramic shafts typically last 3-10 times longer than metal shafts.

Zirconia ceramics have self-lubricating properties. No need to add lubricating oil regularly, reducing downtime and maintenance costs.

Ceramic Shaft Applications

From precision instruments to harsh industrial environments, ceramic shafts are gradually replacing traditional metal shafts with their excellent performance. The following are its most representative application scenarios.

-

Industrial pumps and valves: Resistant to acid and alkali corrosion (such as sulfuric acid and salt water), insulated, and can replace metal shafts that are prone to rust.

-

Textile machinery: The wear resistance is better than metal, which reduces fiber wear and prolongs service life.

-

Food processing equipment: High purity materials ensure no metal ion contamination and meet food grade safety requirements.

-

Industrial automation: High rigidity avoids micro-deformation and is suitable for repeated positioning.

1. The ceramic shaft is chemically inert and can resist strong acids, strong alkalis and organic solvents, preventing rust and electrochemical corrosion, and increasing its life by 5-10 times.

2. Its ultra-high hardness makes its wear resistance 20 times that of stainless steel, which is particularly suitable for medium containing particles.

3. The density is reduced by 30%-50% to achieve energy-saving operation, and there is no metal ion pollution, meeting the cleanliness requirements of food and medicine grades.

4. The insulating properties of ceramics can avoid electrolytic corrosion and static electricity risks, and the performance is stable at high temperatures of 800℃ or deep cold of -196℃.

Need to consider the working conditions.

1. Ultra-high speed + light load: Silicon nitride (Si3N4) is the first choice, taking advantage of its low density + self-lubricating properties.

2. Medium-high speed + impact load: Zirconia (Y-TZP) is selected, taking into account both toughness and speed.

3. Cost-sensitive + medium speed: Alumina (such as 99% Al2O3) is acceptable, but cooling needs to be strengthened.

Of course, we support customization. The information you need to provide is:

1. Drawings: STEP format files are preferred. PDF drawings must be marked with complete tolerances.

2. Working parameters: speed, load, medium type (such as whether it contacts strong acid), temperature range, etc.

3. Special requirements: if any.

Ceramic shafts made of alumina, zirconia, silicon nitride and other materials have excellent insulation (resistivity > 10¹⁴Ω·cm), and are suitable for explosion-proof and anti-static breakdown scenarios.

If you need conductive properties, we can do ceramic surface metallization (Au/Ag/Ni plating, etc.). You are welcome to provide us with a drawing for evaluation.