Technical SPECs

The ceramic materials commonly used for ceramic washers are mainly alumina and zirconia.

| Property | 96%/99% Alumina Washers | Zirconia Washers |

|---|---|---|

| Density | ≥3.65 g/cm³ | ≥6 g/cm³ |

| Flexural Strength | 280–310MPa | 800 MPa |

| Thermal Conductivity | 24-29 W/m·K | 2–3 W/m·K |

| Surface Finish After Machining | Ra 0.4~1.2μm | Ra 0.2~0.5μm |

High-Performance Solutions for Extreme Environments

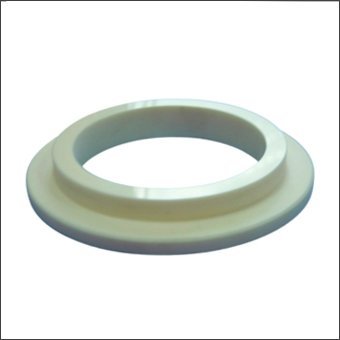

Ceramic washers are precision-engineered components made from advanced materials like alumina (Al2O3) and zirconia (ZrO2), designed to deliver exceptional wear resistance, thermal stability, and electrical insulation. These washers are critical in industries requiring high mechanical strength, corrosion resistance, and longevity, such as electronics and electrical appliances, chemicals and petroleum, and machinery and automation equipment. Their lightweight design and non-magnetic properties further enhance performance in demanding applications.

Product By Features

Our ceramic washers are customized according to customer needs with different characteristics. Below are some representative products. As long as you provide drawings or samples, we can make a 1:1 replica.

High-temperature stability (1,200°C) and fracture toughness.

Ultra-high insulation (>10¹⁴ Ω·cm) for high-voltage systems and electronic components.

Corrosion-resistant sealing in chemical pipelines and acidic/alkaline environments.

Brazable metal coating (Cu/Ag) for vacuum feedthroughs and RF devices.

Split design for easy installation in confined spaces and maintenance-heavy equipment.

Enhanced load-bearing capacity for high-pressure sealing applications.

Distributes stress evenly in aerospace fasteners and automotive suspension systems.

Reduces friction and improves lubrication retention in rotating equipment and pumps.

Key Features

Whether it is wear, high temperature, high pressure or corrosive environment, ceramic washers can stably exert their excellent performance and meet the stringent industrial needs.

Alumina washers achieve Vickers hardness of 1500–1800 HV, reducing wear by 90% compared to metal washers.

Operate continuously at 1600°C (Al₂O₃), ideal for high-temperature environments like aerospace engines.

Resistant to acids, alkalis, and organic solvents, ensuring durability in corrosive settings.

Volume resistivity >10¹⁴ Ω·cm, preventing short circuits in high-voltage systems.

Longer lifespan in abrasive or corrosive environments.

Self-lubricating properties reduce maintenance costs.

Ceramic Washer Applications

Ceramic washers are widely used in the following industrial fields.

-

Electronics and electrical appliances: Used as an insulating washer to prevent current leakage or short circuit. Or as a support and heat dissipation medium for electronic components.

-

Chemical and petroleum: Used as corrosion-resistant seals or reactor liners.

-

Machinery and automation equipment: Used in high-speed equipment to reduce friction and wear, or to protect precision electronic components in high temperature or corrosive environments.

Ceramic washers excel in corrosive settings due to their chemical inertness. For example, alumina ceramics can withstand HCl and NaOH, maintaining their structural integrity, whereas stainless steel will corrode. In chemical processing plants, ceramic washers reduce replacement frequency by 70% and eliminate contamination risks. Their non-porous surface also prevents bacterial growth, critical for pharmaceutical applications.

For high-load systems, prioritize high fracture toughness and compressive strength. Silicon nitride (Si₃N₄) offers superior mechanical strength (700 MPa) and thermal shock resistance, ideal for aerospace turbines. Alumina is better for electrical insulation and cost efficiency. Always match material properties to operational stresses—e.g., zirconia-toughened alumina (ZTA) for extreme wear.

Ceramic washers (especially high-purity Al2O3) have excellent insulation properties, with a volume resistivity of ≥10¹⁴Ω·cm and a dielectric strength of 17-25kV/mm, which are fully suitable for high-voltage electrical applications. In scenarios such as 10kV distribution cabinets and new energy charging piles, it can effectively isolate live parts and prevent arc breakdown while also having a heat dissipation function. Alumina washers (purity of more than 96%) are particularly suitable for high-voltage environments below 100kV.

The surface finish of ceramic washers can usually reach Ra 0.2-1.6μm (alumina/zirconia materials), depending on the forming process and post-processing.

The surface finish of standard dry-pressed parts is generally Ra 1.0-1.6μm, while hot pressing or injection molding combined with precision polishing can achieve an ultra-smooth surface of Ra 0.2-0.8μm.

Whether polishing is required depends on the application scenario: for general sealing and insulation purposes (such as electronic component washers), the original surface can meet the requirements; but in high-precision sealing (such as vacuum systems), fluid equipment or occasions where friction needs to be reduced, polishing is recommended.