Aluminum Nitride Tube Features

The characteristics of aluminum nitride material itself are fully utilized, and after being processed into ceramic tubes, they are used in corresponding scenarios, especially in thermal management and electrical applications.

-High thermal conductivity;

-High mechanical strength under compression load;

-Good thermal shock resistance;

-Low coefficient of thermal expansion;

-Good electrical insulation and resistivity;

-Low dielectric constant.

Aluminum Nitride Tube Manufacturer

If you are looking for a professional AlN tube factory in China, Jinghui ceramic is your first choice. We have over 100 styles of AlN pipe to support your business.

As a special advanced ceramics supplier since 2008, we have 10 expert designers and can supply 2D and 3D drawings based on your project needs or even ideas, you can customize your ceramic tubes, just give your project details, and we will design free for you.

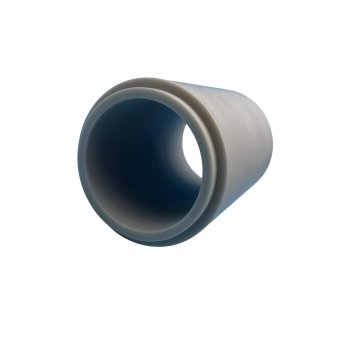

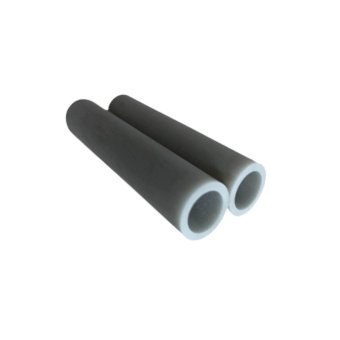

The commonly used forming process for AlN ceramic tubes is isostatic pressing. Laser drilling can be considered during processing, and metallization of the round end surface can also be performed according to customer requirements. We can supply ceramic tubes with various length and diameter. The main size range of the aluminum nitride tube products we produce is outer diameter:5-150 mm, wall thickness: 1-20 mm, length: 10-600 mm.Trust us to provide reliable, customizable solutions to you.

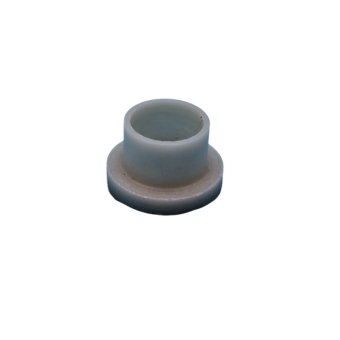

Product By Features

AlN tube is a common product application of aluminum nitride ceramic materials. The aluminum nitride material is guaranteed to have a purity of >99.5% in our AlN ceramic tube. We are able to customize ceramic tubes to your specifications in a variety of shapes, and these products below are just a few of our many offerings.

Aluminum Nitride Tube Applications

-Cooling systems for equipment requiring heat dissipation;

-Thermal insulation sleeves for devices.

– Semiconductor electronic device reactors;

AlN ceramic tubes are used in many industrial fields such as electronics, electricity, locomotives, aerospace, national defense and military industry, communications, etc., and have broad potential markets in laser technology and new energy.

At 25°C, the thermal conductivity of AlN (200W/mK) is 6.7 times that of aluminum oxide (30W/mK); at 300°C, AlN still maintains >180W/mK, while aluminum oxide drops to 15W/mK. This allows AlN tubes to reduce thermal management energy consumption by 40% in semiconductor equipment.

Yes. Through gel casting combined with ultra-precision grinding, we can produce microtubes with an inner diameter of 0.5 mm and a wall thickness of 0.1 mm, with a roundness tolerance of ≤ 0.005 mm. These are suitable for medical laser catheters and MEMS sensor packaging.

Pre-metallization treatment is possible. Active brazing (Ag-Cu-Ti alloy) is used to achieve a welding strength of >50MPa between AlN and Kovar alloy, meeting the vacuum chamber sealing requirements .