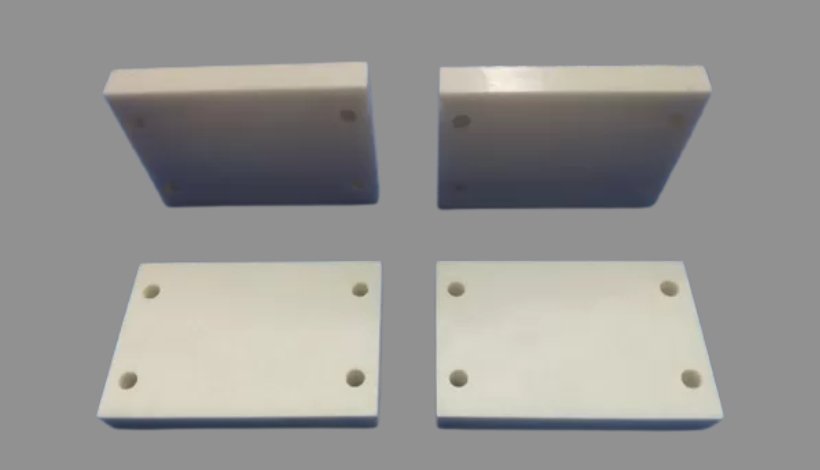

Customization Options

We support custom zirconia plates from prototype to mass production. Even if your specifications differ from those shown on our website, please contact us for options.

- Material: Y-TZP, Mg-PSZ, 3YSZ and 5YSZ ZrO2.

- Thickness: 1mm~50mm.

- Maximum size: 200×200mm (standard).

- Standard tolerance: ±0.02mm for thickness and ±0.05mm for dimensions. Tighter tolerances (e.g., ±0.01mm) are available upon request with CNC grinding.

- Surface roughness: Ra 0.1μm (mirror polish) to Ra 0.5μm (as-sintered).

Partner with the Leading Zirconia Plate Supplier

As your trusted zirconia plate supplier, we always provide high-quality products and reliable delivery. We have a variety of manufacturing options, including isostatic pressing, dry pressing and hot pressing, and can customize the size, shape and surface treatment according to your needs. The products have passed international certifications such as ISO9001, RoHS and REACH.

Our zirconia plates have excellent durability, thermal stability and corrosion resistance. They have been successfully used in industries such as mechanical engineering, high-temperature refractories, chemicals and metallurgy. Contact us now!

By Stabilizers

The performance of zirconia plates is closely related to their material ratios. Y-TZP and Mg-PSZ are the two dominant zirconia ceramic materials. In addition, we also have 3YSZ and 5YSZ. Talk to us about your project and we will be happy to provide you with material selection advice.

Stabilizer: yttria (2-3 mol%), mainly in the tetragonal phase. A representative of high-performance ceramics. Suitable for fields that require high reliability.

Stabilizer: magnesia (3-5 mol%), with partially stable tetragonal + monoclinic phase. Suitable for high economic requirements.

Stabilizer: yttria (about 3 mol%), with partially stabilized zirconia (PSZ) and has excellent mechanical properties and thermal shock resistance.

Stabilizer: yttria (about 5 mol%), with partially stabilized zirconia (PSZ). Its performance is similar to 3YSZ, but its stability is higher.

By Applications

Applications of zirconia plates include but are not limited to industrial machinery and wear-resistant parts, semiconductor and electronic packaging, energy and high-temperature equipment, chemical industry and corrosive environments.

-

Used for wafer carriers, etching trays and vacuum chamber liners to reduce contamination and improve yields.

-

Used in mechanical seals in equipment such as pumps, valves and compressors.

-

Used as electrolyte materials in solid oxide fuel cells to conduct oxygen ions and isolate fuel and oxidant.

-

Used in chemical equipment to reduce equipment failure and downtime caused by corrosion.

Zirconia Plate Vs. Alumina Plate: Who Wins Better in High-Performance Applications?

Do you want to know how to choose between zirconia plates and alumina plates? Let’s take a deep dive into their performance.

- Fracture Toughness

The fracture toughness of zirconia ceramics is usually 6.5-11 MPa∙m1/2. This high toughness is mainly due to the phase transformation toughening mechanism of zirconia: under the action of external force, the tetragonal phase of zirconia will transform into the monoclinic phase, absorbing energy and preventing crack propagation.

The fracture toughness of alumina ceramics is usually 4-5 MPa∙m1/2, which is prone to brittle fracture when subjected to impact or stress.

The high fracture toughness of zirconia plates makes them suitable for occasions that need to withstand impact or vibration, such as mechanical seals.

- Thermal Shock Resistance

Zirconia ceramics have excellent thermal shock resistance, and the critical temperature difference for cracking is >300℃, which can withstand rapid temperature changes without cracking. This is due to the high toughness (phase change toughening mechanism) and low thermal expansion coefficient of zirconia ceramics, which can effectively relieve thermal stress and prevent crack propagation.

The thermal shock resistance of alumina ceramics is relatively poor, and the critical temperature difference for cracking is ≥200℃, which is easy to crack under rapid temperature changes.

The excellent thermal shock resistance of zirconia plates makes them suitable for high temperature and thermal cycle environments, such as aircraft engine components.

- Comparison of Other Properties

- Hardness

The hardness of zirconia ceramics (1070-1230 HV) is slightly lower than that of alumina ceramics (≥1380 HV), but it is still a high-hardness material and is suitable for wear-resistant applications.

- Wear Resistance

The wear resistance of zirconia ceramics is better than that of alumina ceramics, especially under high load and high-speed friction conditions.

- Corrosion Resistance

Both have excellent chemical corrosion resistance, but zirconia ceramics are more stable in strong acid and alkali environments.

- Thermal Conductivity

The thermal conductivity of zirconia ceramics (2.2-3 W/(m∙K)) is lower than that of alumina ceramics (24-31 W/(m∙K)), making it suitable for use as a thermal insulation material.

Summary

Compared with alumina plates, the most unique properties of zirconia plates are their high fracture toughness and excellent thermal shock resistance. These properties give them significant advantages in mechanical seals, high-temperature components, and wear-resistant applications. Although the cost of zirconia plates is higher, its excellent properties make it an irreplaceable material in high-end industrial fields.

Zirconia plates have excellent high temperature stability and can be used for a long time in environments up to 1500℃. Their low thermal conductivity and thermal shock resistance make them an ideal choice for high temperature insulation materials and are widely used in aerospace engine components, thermal protection systems and industrial furnace linings.

Zirconia plates perform extremely well in wear-resistant applications, mainly due to their high hardness, low friction coefficient and excellent wear resistance.

Its typical applications include wear-resistant linings for mining and metallurgical equipment, mechanical seal support plates in pumps and valves, and guide rails and slides in high-precision machine tools and automation equipment.

Zirconia plates have excellent insulating properties. They have high resistivity, high breakdown voltage and excellent temperature stability, making them ideal for insulation applications in high temperature and high voltage environments.

For example, zirconia plates can be used for insulation components of equipment such as transformers, power modules, capacitors, insulation protection of high-temperature sensors in the aerospace and energy fields, and insulation gaskets for electric heating equipment and industrial heaters.

Yes. We laser-cut and CNC grind complex geometries (min. hole diameter 0.3mm). Please share your CAD file for production feasibility analysis.

The price of zirconia plate is affected by factors such as material formula, thickness, dimensional accuracy, surface treatment, etc. Generally speaking, its price is more expensive than that of alumina plate. This is because the raw material cost of high-purity ZrO₂ powder are 5-8x higher than Al₂O₃, and sintering requires precise temperature control. However, zirconia’s longevity offsets this cost. For example, in industrial machinery, the long life of zirconia plates reduces replacement frequency and maintenance costs.